This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3637075 Wiring Harness is a specialized component designed for use in commercial trucks. It serves as a link in the vehicle’s electrical system, facilitating the connection between various electrical components and ensuring the proper transmission of signals and power. Its role is significant in maintaining the operational integrity of the truck’s electrical infrastructure.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches that transmit electrical power and signals between different components of a vehicle. It is designed to organize and protect the wires, reducing the risk of damage and ensuring efficient signal transmission. Within a vehicle’s electrical system, the wiring harness plays a role by providing a structured pathway for electricity to flow from the power source to the various electrical components, such as lights, sensors, and control units 1.

Purpose of the 3637075 Wiring Harness

The Cummins 3637075 Wiring Harness is specifically engineered to serve within the electrical system of a truck. It functions by connecting a wide array of electrical components, ensuring that signals and power are transmitted accurately and efficiently. This harness is integral to the operation of the truck, as it supports the functionality of critical systems such as the engine control unit, sensors, and lighting systems, thereby contributing to the overall performance and reliability of the vehicle 2.

Key Features

The Cummins 3637075 Wiring Harness is characterized by several key features that enhance its performance and durability. Its design incorporates high-quality materials that are resistant to wear, corrosion, and environmental factors, ensuring long-term reliability. The harness is also engineered with precision to fit securely within the truck’s electrical system, minimizing the risk of disconnections or faults. Additionally, it may include unique characteristics such as integrated surge protection or specialized connectors that further enhance its functionality.

Benefits

The use of the Cummins 3637075 Wiring Harness offers several advantages. It contributes to improved reliability by ensuring stable and consistent electrical connections. This reduces the risk of electrical faults that could lead to system failures or inefficiencies. Furthermore, the harness enhances the overall performance of the truck’s electrical system, supporting the efficient operation of all connected components. Its robust design and high-quality materials also contribute to its longevity, providing value over the vehicle’s lifespan.

Installation Considerations

Proper installation of the Cummins 3637075 Wiring Harness is crucial for ensuring optimal performance and longevity. It is important to follow manufacturer guidelines closely, paying attention to specific requirements such as secure mounting and correct routing of wires to avoid damage. Precautions should be taken to protect the harness from physical damage and environmental factors during installation. Ensuring that all connections are secure and correctly aligned will help maintain the integrity of the electrical system.

Troubleshooting and Maintenance

Regular maintenance and prompt troubleshooting are key to prolonging the lifespan of the Cummins 3637075 Wiring Harness and ensuring continued reliable operation. Inspecting the harness for signs of wear, corrosion, or damage can help identify potential issues before they lead to system failures. Addressing any detected issues promptly, such as repairing or replacing damaged sections, is important. Additionally, keeping the harness clean and protected from environmental factors can help maintain its condition and performance.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, emissions solutions, and related technologies. With a strong reputation in the industry for quality and innovation, Cummins is committed to advancing technology for a better world. The company’s dedication to excellence is evident in its products, including the Cummins 3637075 Wiring Harness, which exemplifies its commitment to providing reliable and high-performance automotive components.

Cummins Engine Wiring Harness 3637075 Compatibility

The Cummins Wiring Harness part number 3637075 is designed to be compatible with several of Cummins’ engine models. Specifically, this wiring harness is engineered to fit seamlessly with the following engines:

- QSK45 CM500

- QSK60 CM500

- QSK60 CM850 MCRS

This part is integral to the electrical system of these engines, ensuring that all necessary components are properly connected and that the engine operates efficiently. The harness is built to withstand the rigors of engine operation, providing reliable electrical connections that are critical for the performance and longevity of the engine.

When installing the wiring harness, it is essential to follow the manufacturer’s guidelines to ensure that all connections are secure and that the harness is routed correctly to avoid any potential interference with other engine components. Proper installation of this part is crucial for maintaining the integrity of the engine’s electrical system and ensuring optimal performance.

Role of Part 3637075 Wiring Harness in Engine Systems

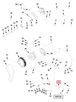

The 3637075 Wiring Harness is integral to the efficient operation of various engine components, particularly the drive and fan systems.

Drive System Integration

In the drive system, the 3637075 Wiring Harness facilitates the electrical connections necessary for the operation of the drive motor. It ensures that power is efficiently distributed from the power source to the motor, enabling smooth and reliable operation. The harness also incorporates sensors and feedback mechanisms that allow for real-time monitoring of the drive’s performance, ensuring optimal functionality and immediate detection of any irregularities.

Fan System Integration

For the fan system, the 3637075 Wiring Harness plays a significant role in managing the electrical supply to the fan motor. It ensures that the fan operates at the correct speed to maintain appropriate engine temperature, enhancing overall engine efficiency. The harness is designed to handle the varying electrical loads that the fan may experience, providing a stable and consistent power supply. Additionally, it includes connections for temperature sensors, which help in regulating the fan speed based on the engine’s thermal conditions, thus preventing overheating and ensuring prolonged engine life.

Conclusion

The Cummins 3637075 Wiring Harness is a critical component in the electrical systems of commercial trucks, particularly those equipped with Cummins engines. Its design and features ensure reliable and efficient operation of the truck’s electrical components, contributing to the overall performance and reliability of the vehicle. Proper installation, regular maintenance, and prompt troubleshooting are essential for maximizing the lifespan and effectiveness of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.