This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3628758 Wiring Harness is a specialized component designed for use in commercial trucks. It serves as an essential element in the vehicle’s electrical system, facilitating the connection between various electrical components and the truck’s power source. This wiring harness ensures that electrical signals and power are efficiently distributed throughout the truck, contributing to its overall operational efficiency and reliability.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches and relays that transmit electrical power and signals between different parts of a vehicle. It is designed to organize and protect the wires, reducing the risk of damage and ensuring reliable performance. Within a vehicle’s electrical system, the wiring harness plays a vital role by providing a structured pathway for electricity to flow from the power source to the components that require it, such as lights, sensors, and control units 1.

Purpose of the 3628758 Wiring Harness

The Cummins 3628758 Wiring Harness is specifically engineered to support the electrical needs of commercial trucks. It integrates with the truck’s engine control module (ECM), sensors, and other electrical components, ensuring that they receive the necessary power and signals to function correctly. This harness is designed to withstand the harsh conditions often encountered in commercial trucking, such as vibrations, temperature extremes, and exposure to moisture 2.

Key Features

The Cummins 3628758 Wiring Harness is characterized by its robust design and high-quality materials. It is constructed using durable wires and connectors that are resistant to wear and environmental factors. The harness is also designed with flexibility in mind, allowing it to be routed through the truck’s chassis without compromising its integrity. Additionally, it may include unique features such as integrated fuses or relays to enhance safety and functionality 3.

Benefits of Using the 3628758 Wiring Harness

Utilizing the Cummins 3628758 Wiring Harness offers several advantages. It contributes to improved efficiency by ensuring that electrical components receive a stable and consistent power supply. The harness also enhances reliability, reducing the likelihood of electrical failures that could lead to downtime. Furthermore, it plays a role in safety by providing a secure and organized pathway for electrical currents, minimizing the risk of short circuits or electrical fires.

Installation Process

Installing the Cummins 3628758 Wiring Harness requires careful attention to detail. The process involves routing the harness through the truck’s chassis, connecting it to the appropriate electrical components, and securing it in place. Tools such as wire strippers, crimping tools, and zip ties may be required. It is important to follow the manufacturer’s instructions to ensure proper installation and avoid damaging the harness or other components.

Common Issues and Troubleshooting

Wiring harnesses can encounter issues such as frayed wires, loose connections, or corrosion. These problems can lead to electrical malfunctions or failures. Troubleshooting may involve inspecting the harness for visible damage, testing electrical connections with a multimeter, and repairing or replacing damaged sections as necessary. Regular inspections can help identify potential issues before they become serious problems.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 3628758 Wiring Harness, regular maintenance is recommended. This includes inspecting the harness for signs of wear or damage, ensuring that all connections are secure, and protecting the harness from moisture and debris. Keeping the harness clean and free from obstructions can also contribute to its reliable operation.

Safety Considerations

When working with the Cummins 3628758 Wiring Harness, it is important to observe safety guidelines to prevent accidents and injuries. This includes disconnecting the truck’s battery before beginning any electrical work, using insulated tools to avoid electrical shocks, and wearing appropriate personal protective equipment. Additionally, it is crucial to follow all manufacturer instructions and safety recommendations during installation and maintenance.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the commercial truck industry. The company’s commitment to excellence is reflected in its products, including the Cummins 3628758 Wiring Harness, which is designed to meet the demanding requirements of commercial trucking applications.

Compatibility

The Cummins Wiring Harness part number 3628758 is designed to integrate seamlessly with a variety of Cummins engines, ensuring reliable electrical connections and optimal performance. This wiring harness is compatible with the following engines:

K38 and K50 Engines

The K38 and K50 engines benefit from the precise wiring harness connections provided by the 3628758. These engines, known for their robust performance, require a dependable wiring system to manage the electrical demands effectively.

QSK45 CM500 and QSK60 CM500 Engines

For the QSK45 CM500 and QSK60 CM500 engines, the 3628758 wiring harness is engineered to handle the higher electrical loads and complex wiring configurations. This ensures that the engines operate smoothly and efficiently, with all necessary electrical components properly connected.

QSK60G Engine

The QSK60G engine, part of the QSK series, also integrates well with the 3628758 wiring harness. This engine, designed for heavy-duty applications, relies on a precise and durable wiring system to maintain its high performance and reliability.

Grouping of Engines

The engines mentioned can be grouped based on their series and intended applications. The K38 and K50 engines are typically used in medium-duty applications, while the QSK45 CM500, QSK60 CM500, and QSK60G engines are designed for heavy-duty and industrial use. The 3628758 wiring harness is tailored to meet the specific electrical needs of these engine groups, ensuring compatibility and performance across different applications.

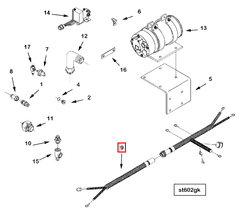

Role of Part 3628758 Wiring Harness in Engine Systems

The Part 3628758 Wiring Harness is an integral component in the electrical system of various engine setups. It facilitates the connection between multiple engine components, ensuring seamless communication and operation. Here’s how it integrates with the provided components:

Integration with Components

Prelub Electrical Remote Kit and Prelub Remote Kit

The Wiring Harness connects the prelub electrical remote kit and the prelub remote kit to the engine’s electrical system. This ensures that the prelub system, which primes the engine with oil before starting, receives the necessary power and signals to operate correctly.

Motor and Starting System

For the motor and starting system, the Wiring Harness provides the essential electrical connections needed for the starting motor to engage. It routes power from the battery to the starter motor, enabling the engine to crank and start. Additionally, it ensures that the starting motor receives the correct signals from the ignition system.

Mounting and Starting Motor

When dealing with the mounting and starting motor components, the Wiring Harness plays a key role in securing electrical connections. It ensures that the starting motor, once mounted, can communicate with other engine systems, such as the ignition and battery, to facilitate a smooth start-up process.

Plumbing and Engine Oil Primer

In systems that include plumbing and an engine oil primer, the Wiring Harness is responsible for connecting the oil primer to the engine’s electrical system. This allows the primer to operate efficiently, ensuring that the engine is adequately lubricated before and during operation.

Prelub Air Starter (LB and RB) and Prelub Starter

For the prelub air starter (left bank and right bank) and the prelub starter, the Wiring Harness ensures that these components receive the necessary electrical power. This is vital for the prelub system to function correctly, providing the engine with the required lubrication prior to start-up.

Remote Installation Kit

In scenarios where a remote installation kit is used, the Wiring Harness extends the electrical connections to allow for remote operation of the engine. This is particularly useful in applications where the engine needs to be started from a distance, ensuring safety and convenience.

Overall, the Part 3628758 Wiring Harness is a fundamental element in the electrical architecture of engine systems, ensuring that all components work in unison for optimal engine performance.

Conclusion

The Cummins 3628758 Wiring Harness is a critical component in the electrical systems of commercial trucks and various Cummins engines. Its robust design, high-quality materials, and compatibility with a range of engines make it an essential part for ensuring reliable and efficient operation. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part, contributing to the overall performance and safety of the vehicle.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.