This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3093667 Wiring Harness is a specialized component designed for use in commercial trucks. It serves as a vital part of the vehicle’s electrical system, facilitating the connection between various electrical components and the truck’s power source. This wiring harness ensures that electrical signals and power are efficiently distributed throughout the truck, contributing to the overall functionality and performance of the vehicle.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches and relays that transmit electrical power and signals between different components of a vehicle. It typically includes insulated wires bundled together, connectors for joining wires, and protective housing to shield the wires from physical damage and environmental factors. Within a vehicle’s electrical system, the wiring harness plays a role in ensuring that all electrical components receive the necessary power and signals to operate correctly 1.

Purpose of the 3093667 Wiring Harness

The Cummins 3093667 Wiring Harness is designed to integrate seamlessly with the electrical systems of commercial trucks. It connects various electrical components, such as sensors, lights, and control units, to the truck’s power source. This integration allows for the efficient distribution of electrical power and signals, ensuring that all components function as intended. The harness also plays a role in protecting the wires from damage, reducing the risk of electrical faults and improving the reliability of the truck’s electrical system 2.

Key Features

The Cummins 3093667 Wiring Harness is characterized by its robust design and high-quality materials. It is constructed using durable, insulated wires that are resistant to abrasion, heat, and chemicals. The harness is also designed to be flexible, allowing it to be routed through the tight spaces within a truck’s chassis. Additionally, it features secure connectors that ensure a reliable electrical connection between components. These features contribute to the harness’s longevity and performance in demanding commercial truck applications 3.

Benefits

The Cummins 3093667 Wiring Harness offers several advantages. Its robust construction and high-quality materials contribute to improved reliability, reducing the likelihood of electrical faults. The efficient distribution of power and signals enhances the overall efficiency of the truck’s electrical system. Furthermore, the protective features of the harness contribute to increased safety by minimizing the risk of electrical fires and other hazards associated with faulty wiring 4.

Installation Considerations

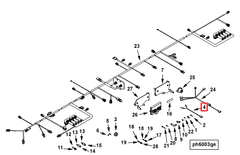

When installing the Cummins 3093667 Wiring Harness, it is important to follow the manufacturer’s guidelines to ensure proper integration with the truck’s electrical system. This may involve disconnecting the battery to prevent electrical shocks, routing the harness through designated pathways to avoid damage, and securing it in place using appropriate fasteners. Special tools may be required to connect and disconnect the harness from other components, so it is advisable to have the necessary equipment on hand.

Troubleshooting Common Issues

Common issues with wiring harnesses can include loose connections, damaged wires, and faulty connectors. To address these problems, it is important to inspect the harness regularly for signs of wear or damage. Loose connections can often be tightened or reconnected, while damaged wires may need to be repaired or replaced. Faulty connectors should be replaced to ensure a reliable electrical connection. Regular maintenance and inspections can help identify and resolve these issues before they lead to more significant problems.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 3093667 Wiring Harness, regular maintenance is recommended. This includes inspecting the harness for signs of wear, damage, or corrosion, and cleaning it to remove any dirt or debris that may accumulate over time. It is also important to ensure that all connections are secure and that the harness is properly routed and secured within the truck’s chassis. Following these maintenance practices can help prevent electrical issues and extend the life of the wiring harness.

Safety Precautions

When working with the Cummins 3093667 Wiring Harness, it is important to observe several safety precautions. Always disconnect the battery before beginning any work on the electrical system to prevent electrical shocks. Use appropriate personal protective equipment, such as gloves and safety glasses, to protect yourself from potential hazards. Additionally, ensure that all tools and equipment are in good working condition to avoid accidents. Following these safety measures can help prevent injuries and ensure a safe working environment.

Cummins Overview

Cummins is a well-established company with a strong reputation in the commercial truck industry. Founded in 1919, Cummins has a long history of innovation and excellence in engine and power generation technologies. The company is known for its commitment to quality, reliability, and customer satisfaction, making it a trusted name among commercial truck manufacturers and operators. Cummins’ extensive product line and global presence underscore its leadership in the industry.

Cummins Wiring Harness 3093667 Compatibility

The Cummins Wiring Harness part number 3093667 is designed to seamlessly integrate with a variety of engine models, ensuring reliable electrical connectivity and optimal performance. This wiring harness is engineered to fit specific Cummins engines, providing a critical link between various electrical components and the engine control unit (ECU).

QST30 CM552 Engines

The 3093667 wiring harness is compatible with the QST30 CM552 engines. This compatibility ensures that the harness can effectively manage the electrical needs of these engines, facilitating smooth operation and efficient power distribution. The harness is designed to withstand the operational stresses of these engines, ensuring durability and longevity.

Grouping of Compatible Engines

The Cummins Wiring Harness 3093667 is also suitable for a broader range of engines within the Cummins lineup. This harness is engineered to fit engines that share similar electrical architectures and requirements, ensuring that it can be used across multiple models without modification. This versatility makes it an essential component for maintaining the electrical integrity of these engines.

By ensuring that the wiring harness is compatible with these engines, Cummins provides a reliable solution for maintaining the electrical systems of their engines, enhancing overall performance and reliability.

Role of Part 3093667 Wiring Harness in Engine Systems

The 3093667 Wiring Harness is an integral component in the orchestration of various engine systems, facilitating seamless communication and operation among them.

Integration with the Engine Control Module (ECM)

The wiring harness establishes a vital connection between the Engine Control Module (ECM) and other engine components. This link ensures that the ECM receives accurate and timely data from sensors and actuators, allowing it to make precise adjustments to engine parameters such as fuel injection timing, ignition timing, and valve timing. The harness also transmits control signals from the ECM to various actuators, ensuring that the engine operates efficiently and within specified parameters.

Sensor Data Transmission

Sensors play a pivotal role in modern engine management systems by providing real-time data on various engine conditions. The 3093667 Wiring Harness is responsible for transmitting data from sensors such as the Manifold Absolute Pressure (MAP) sensor, Mass Air Flow (MAF) sensor, and Oxygen (O2) sensor to the ECM. This data is essential for the ECM to make informed decisions regarding fuel delivery and ignition timing. Additionally, temperature sensors, including the Engine Coolant Temperature (ECT) sensor and Intake Air Temperature (IAT) sensor, rely on the wiring harness to convey temperature data to the ECM, enabling it to adjust engine operation based on thermal conditions.

Pressure and Temperature Regulation

The wiring harness also facilitates the operation of pressure and temperature regulation systems within the engine. For instance, it connects the ECM to the Fuel Pressure Regulator (FPR), allowing the ECM to modulate fuel pressure based on engine load and RPM. Similarly, the harness links the ECM to the Exhaust Gas Recirculation (EGR) valve, enabling the ECM to control the flow of exhaust gases back into the intake manifold to reduce emissions and improve fuel efficiency. Temperature-related components, such as the Thermostat and Radiator Fan, also rely on the wiring harness to receive control signals from the ECM, ensuring that the engine maintains optimal operating temperatures.

In summary, the 3093667 Wiring Harness is a cornerstone of modern engine management systems, enabling the ECM to monitor and control a wide array of engine components and systems. Its role in data transmission and control signal distribution is indispensable for the efficient and reliable operation of contemporary engines.

Conclusion

The Cummins 3093667 Wiring Harness is a critical component in the electrical systems of commercial trucks, ensuring efficient power and signal distribution. Its robust design, high-quality materials, and compatibility with various Cummins engines make it an essential part for maintaining the electrical integrity and performance of these vehicles. Regular maintenance, proper installation, and adherence to safety precautions are key to maximizing the benefits of this Cummins part.

-

Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles, Andrew Brown Jr, National Academy of Sciences, 2010

↩ -

Haynes Manual on Diesel Engines, Martynn Randall, Haynes Publishing, 2015

↩ -

Automotive Emissions Regulations and Exhaust Aftertreatment Systems, John Kasab and Andrea Strzelec, SAE International, 2020

↩ -

Modelling Diesel Combustion, P A Lakshminarayanan and Yogesh V Aghav, Springer Science, 2010

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.