This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

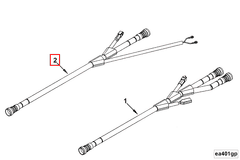

The Cummins 2896531 Wiring Harness is a specialized component designed for use in commercial trucks. It serves as an essential element in the vehicle’s electrical system, facilitating the connection between various electrical components and ensuring the smooth operation of the truck. Its role is significant, as it contributes to the overall functionality and efficiency of the truck’s electrical network.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and terminals that transmit electrical power and signals between different components within a vehicle 1. It is designed to organize and protect the wires, reducing the risk of damage and ensuring reliable electrical connections. Within a vehicle’s electrical system, the wiring harness plays a vital role by providing a structured pathway for electrical current to flow, enabling the operation of lights, sensors, and other electrical devices.

Purpose of the 2896531 Wiring Harness

This Cummins part is specifically engineered to integrate with the electrical systems of commercial trucks. It connects various electrical components, such as sensors, lights, and control modules, ensuring they receive the necessary power and signals to function correctly. This harness is designed to work in conjunction with other electrical systems, contributing to the overall performance and reliability of the truck.

Key Features

The 2896531 Wiring Harness boasts several key features that enhance its performance and durability. Its design includes high-quality materials that are resistant to wear and environmental factors, ensuring long-lasting operation. The harness is also engineered with precision to fit securely within the truck’s electrical system, minimizing the risk of loose connections. Additionally, it incorporates protective measures to safeguard the wires from physical damage and corrosion.

Benefits

The implementation of this Cummins part offers several benefits. It contributes to improved electrical efficiency by providing a direct and organized pathway for electrical current. This reduces the risk of short circuits and enhances the reliability of the truck’s electrical system. Furthermore, the harness’s durable construction ensures it can withstand the demanding conditions of commercial truck operations, leading to a longer service life.

Installation Considerations

Proper installation of the 2896531 Wiring Harness is crucial for its effective operation. It is important to follow manufacturer guidelines to ensure the harness is correctly positioned and securely connected. Special tools may be required for installation, and it is advisable to consult the vehicle’s manual or seek professional assistance to avoid potential issues 2.

Troubleshooting Common Issues

Common issues with wiring harnesses may include loose connections, damaged wires, or corrosion. Troubleshooting steps involve inspecting the harness for visible damage, ensuring all connections are secure, and testing for electrical continuity. Solutions may range from tightening connections to replacing damaged sections of the harness.

Maintenance Tips

To ensure the optimal performance and longevity of the 2896531 Wiring Harness, regular maintenance is recommended. This includes periodic inspections for signs of wear or damage, cleaning the harness to remove dirt and debris, and ensuring all connections remain tight and secure. Adhering to these maintenance practices can help prevent electrical issues and extend the life of the harness.

Safety Precautions

When working with the 2896531 Wiring Harness, it is important to observe safety precautions. This includes disconnecting the battery before beginning any work to prevent electrical shocks. Additionally, handling the harness with care and using appropriate tools can help avoid damage to the wires and connectors. Following electrical safety guidelines is crucial to ensure a safe working environment.

About Cummins

Cummins is a renowned manufacturer with a long-standing reputation in the industry for producing high-quality automotive and heavy-duty truck parts. The company is committed to innovation and excellence, consistently delivering products that meet the demanding requirements of commercial vehicle operations. Cummins’ dedication to quality and customer satisfaction has established it as a trusted name in the field.

Cummins Engine Wiring Harness 2896531 Compatibility

This Cummins part is designed to integrate seamlessly with a range of Cummins engines, ensuring reliable electrical connectivity and performance. The wiring harness is compatible with the following engine models:

- QSK19 CM850 MCRS

- QSK50 CM2150 K107

- QSK50 CM2150 MCRS

- QSK60 CM850 MCRS

For the QSK19 CM850 MCRS and QSK60 CM850 MCRS engines, the wiring harness is engineered to handle the specific electrical demands of these models, ensuring that all components are properly powered and controlled. The harness is designed to fit precisely, minimizing the risk of electrical faults and enhancing overall system reliability.

In the case of the QSK50 CM2150 K107 and QSK50 CM2150 MCRS engines, the wiring harness is tailored to meet the higher power requirements and more complex electrical systems of these engines. This ensures that the harness can support the increased load and provide stable power distribution across the engine’s various systems.

By using the Cummins Wiring Harness part number 2896531, technicians and operators can be confident in the compatibility and performance of the harness across these engine models, facilitating easier maintenance and reducing downtime.

Role of Part 2896531 Wiring Harness in Engine Systems

The Part 2896531 Wiring Harness is an integral component in the electrical system of engine assemblies, facilitating the connection between various electrical components and the main power source. This harness is designed to route electrical signals and power efficiently, ensuring that all connected systems operate harmoniously.

Integration with Engine Components

-

Harness: The primary function of the wiring harness is to serve as the backbone of the electrical system. It connects the battery to the starter motor, ignition system, and other critical electrical components. This ensures that power is distributed effectively throughout the engine system.

-

Main Extension: The main extension of the wiring harness extends the reach of the primary harness, allowing it to connect to components that are located further away from the central power source. This includes sensors, fuel injectors, and other peripheral devices that require a stable and consistent power supply.

Electrical Signal Routing

The wiring harness is responsible for routing electrical signals from the engine control unit (ECU) to various sensors and actuators. This includes:

- Oxygen Sensors: These sensors monitor the oxygen content in the exhaust gases and send data to the ECU, which then adjusts the air-fuel mixture accordingly.

- Throttle Position Sensor: This sensor detects the position of the throttle and sends this information to the ECU, allowing for precise control of the engine’s power output.

- Fuel Injectors: The harness supplies power to the fuel injectors, enabling them to deliver the correct amount of fuel into the combustion chamber at the right time.

Power Distribution

In addition to signal routing, the wiring harness ensures that power is distributed to all necessary components, including:

- Ignition Coils: These components require a consistent power supply to generate the high voltage needed for spark plug ignition.

- Cooling Fans: The harness provides power to the cooling fans, which help maintain optimal engine temperature by dissipating heat.

- Lighting Systems: Interior and exterior lighting systems are also connected via the wiring harness, ensuring they receive the necessary power to operate.

Safety and Reliability

The wiring harness is engineered to withstand the harsh environment of the engine compartment, including exposure to heat, vibration, and moisture. Its robust construction ensures reliable performance, minimizing the risk of electrical failures that could lead to engine malfunctions.

By efficiently managing the distribution of power and electrical signals, the Part 2896531 Wiring Harness plays a significant role in the overall performance and reliability of engine systems.

Conclusion

The Cummins 2896531 Wiring Harness is a critical component in the electrical systems of commercial trucks and Cummins engines. Its design and features ensure reliable power distribution and signal routing, contributing to the overall performance and efficiency of the vehicle. Proper installation, maintenance, and adherence to safety precautions are essential to maximize the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.