This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

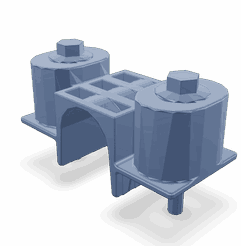

The Cummins 5298539 Retaining Clamp is a specialized component designed for use in commercial trucks. Its primary role is to secure various parts within the engine assembly, ensuring they remain in place under operational conditions. This clamp is particularly relevant for Cummins engines, where it contributes to the overall efficiency and reliability of the engine system 1.

Purpose and Function

The retaining clamp plays a role in the operation of a truck by securing components within the engine, preventing them from shifting or becoming dislodged during engine operation. In Cummins engines, this clamp is applied to hold specific parts in position, which is vital for the engine’s performance and longevity. By maintaining the correct alignment and position of engine components, the clamp helps ensure smooth operation and reduces the risk of damage due to component misalignment 2.

Key Features

The design and construction of the 5298539 Retaining Clamp incorporate several features that enhance its functionality and durability. Constructed from high-strength materials, the clamp is built to withstand the rigors of commercial truck operation. Its design allows for a secure fit around the components it is meant to hold, ensuring stability. The clamp’s build quality is a testament to Cummins’ commitment to producing reliable and durable parts for the commercial trucking industry 3.

Benefits

The advantages provided by the 5298539 Retaining Clamp include improved reliability of the engine components it secures, ease of installation due to its design, and durability that matches the demanding conditions of commercial truck use. These benefits contribute to the overall efficiency and maintenance of the truck’s engine system, reducing downtime and enhancing performance 4.

Installation Process

Installing the retaining clamp requires following a series of steps to ensure it is securely fastened and functions as intended. The process involves identifying the correct position for the clamp, using the appropriate tools to install it, and verifying that it is properly secured. Detailed instructions and any necessary tools should be referenced to ensure a correct installation 5.

Maintenance and Troubleshooting

Maintaining the retaining clamp involves regular inspections to ensure it remains in good condition and securely fastened. Common issues may include wear or damage to the clamp, which can affect its ability to hold components in place. Troubleshooting steps may involve replacing the clamp if it shows signs of wear or adjusting its position if it becomes loose 6.

Safety Considerations

When installing or maintaining the retaining clamp, it is important to observe safety guidelines to prevent injury or damage. This includes ensuring the engine is off and cool before beginning work, using the correct tools for installation, and following all manufacturer recommendations for maintenance and replacement 7.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins plays a significant role in the commercial truck industry, providing reliable and efficient engine solutions for a wide range of applications. The company’s commitment to quality and performance is evident in its product line, including components like the 5298539 Retaining Clamp 8.

Role of Part 5298539 Retaining Clamp in Engine Systems

The Part 5298539 Retaining Clamp is instrumental in ensuring the secure and efficient operation of various engine components. When integrated with a Wiring Harness Repair Kit, the Retaining Clamp plays a significant role in maintaining the integrity and functionality of the electrical systems within the engine.

Secure Wiring Connections

One of the primary functions of the Retaining Clamp in conjunction with the Wiring Harness Repair Kit is to secure wiring connections. This ensures that all electrical wires are held firmly in place, preventing any unwanted movement that could lead to disconnections or shorts. The clamp helps to maintain consistent electrical conductivity, which is essential for the reliable operation of engine systems 9.

Protection Against Vibration

Engines are subject to constant vibration during operation. The Retaining Clamp helps to mitigate the effects of this vibration on the wiring harness. By holding the wires securely, it reduces the risk of wires becoming frayed or damaged over time. This protection is vital for the longevity and reliability of the electrical components within the engine 10.

Facilitation of Repairs and Maintenance

When using a Wiring Harness Repair Kit, the Retaining Clamp simplifies the repair process. It allows for easy access to the wiring harness while ensuring that the repaired sections remain stable and protected. This makes maintenance and repairs more efficient, reducing downtime and enhancing the overall reliability of the engine system 11.

Enhancement of Electrical System Performance

By ensuring that all wiring connections are secure and protected, the Retaining Clamp contributes to the optimal performance of the engine’s electrical system. This includes improved signal transmission, reduced risk of electrical faults, and overall enhanced engine efficiency 12.

Conclusion

In summary, the Part 5298539 Retaining Clamp, when used with a Wiring Harness Repair Kit, plays a vital role in maintaining the secure, protected, and efficient operation of engine electrical systems. Its design and functionality contribute to the overall reliability and performance of Cummins engines, making it an essential component for commercial truck applications.

-

Reif, Konrad. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Eret, Angelina. Dynamic and Fatigue Assessment of Heavy-Duty Engine Valves. Springer Nature, 2024.

↩ -

Fijalkowski, BT. Automotive Mechatronics Operational and Practical Issues Volume 1. Springer, 2011.

↩ -

Cummins Inc. Service Manual (5579482).

↩ -

Cummins Inc. Service Manual (5579482).

↩ -

Cummins Inc. Service Manual (5579482).

↩ -

Cummins Inc. Service Manual (5579482).

↩ -

Cummins Inc. Service Manual (5579482).

↩ -

Cummins Inc. Service Manual (5579482).

↩ -

Cummins Inc. Service Manual (5579482).

↩ -

Cummins Inc. Service Manual (5579482).

↩ -

Cummins Inc. Service Manual (5579482).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.