This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 5258019 Retaining Ring is a specialized component designed for use in commercial trucks. Its primary role is to secure various parts within the truck’s engine and other mechanical systems, ensuring they remain in place under operational conditions. This part is integral to maintaining the structural integrity and functionality of the components it secures, contributing to the overall performance and reliability of the vehicle 4.

Basic Concepts of Retaining Rings

Retaining rings, also known as circlips, are mechanical fasteners used to prevent components from moving along a shaft or within a housing. They operate by fitting into a groove and exerting a radial force that holds parts in place. Retaining rings are widely used in various mechanical systems due to their simplicity, effectiveness, and ease of installation and removal 1.

Purpose of the 5258019 Retaining Ring

The Cummins 5258019 Retaining Ring plays a specific role in the operation of commercial trucks by securing components within the engine or other systems. It ensures that parts such as gears, bearings, and shafts remain correctly positioned, which is vital for the smooth operation and longevity of the mechanical systems. By maintaining the proper alignment and positioning of these components, the retaining ring contributes to the efficient functioning of the truck 2.

Key Features

The Cummins 5258019 Retaining Ring is characterized by several key features that enhance its performance. It is typically made from high-strength materials such as steel or stainless steel, ensuring durability and resistance to wear. The design of the ring includes precise dimensions and a robust construction to withstand the operational stresses encountered in commercial trucks. Additionally, the ring may feature specific coatings or treatments to improve corrosion resistance and longevity 3.

Benefits

The advantages provided by the Cummins 5258019 Retaining Ring include improved reliability, efficiency, and longevity of the components it secures. By ensuring that parts remain in their intended positions, the ring helps prevent mechanical failures and reduces the need for frequent maintenance. This results in enhanced performance and durability of the truck’s engine and other systems, contributing to overall operational efficiency 4.

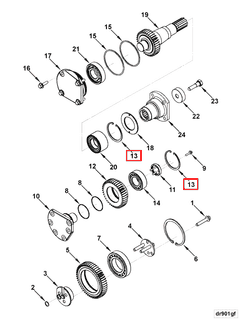

Installation Process

Proper installation of the Cummins 5258019 Retaining Ring involves several steps to ensure correct fitting. The process typically requires the use of specialized tools such as retaining ring pliers. The groove where the ring will be installed should be clean and free of debris. The ring is then carefully placed into the groove, ensuring it is seated correctly and exerts the necessary radial force to secure the component. Following manufacturer guidelines and best practices is important to achieve a secure and effective installation 1.

Common Issues and Troubleshooting

Typical problems associated with retaining rings include improper installation, wear, and corrosion. Diagnosing issues may involve inspecting the ring for signs of damage or misalignment and checking the components it secures for proper positioning. Troubleshooting tips include ensuring the groove is clean and free of debris before installation, using the correct tools, and verifying that the ring is the appropriate size for the application. Regular inspections can help identify and address potential issues before they lead to mechanical failures 2.

Maintenance Tips

Regular maintenance of the Cummins 5258019 Retaining Ring involves periodic inspection for signs of wear, corrosion, or damage. It is important to check that the ring remains securely in place and that the components it secures are functioning correctly. If signs of wear or damage are detected, the ring should be replaced to prevent potential mechanical issues. Following manufacturer recommendations for inspection intervals and maintenance procedures will help ensure the longevity and reliability of the retaining ring and the components it secures 3.

Manufacturer Information - Cummins

Cummins is a renowned manufacturer in the automotive and heavy-duty truck industry, known for its commitment to quality and innovation. The company has a long-standing reputation for producing reliable and high-performance components, including the Cummins 5258019 Retaining Ring. Cummins’ dedication to excellence is reflected in their rigorous testing and quality control processes, ensuring that their products meet the demanding requirements of commercial truck applications 4.

Cummins Retaining Ring Part 5258019 Compatibility

The Cummins Retaining Ring part number 5258019 is a critical component that is compatible with several of Cummins’ engine models. This part is designed to secure and stabilize various engine parts, ensuring optimal performance and longevity of the engine.

Compatible Engines

- B6.7 G CMOH6.0 B125

- ISB/ISD6.7 CM2150 SN, ISBE CM2150

- ISBE4 CM850

- QSB7 CM2880 B117

Grouping of Compatible Engines

Group 1: B6.7 G CMOH6.0 B125

This engine model benefits from the retaining ring in maintaining the integrity of its components, ensuring smooth operation and reducing wear and tear.

Group 2: ISB/ISD6.7 CM2150 SN, ISBE CM2150

The ISB/ISD6.7 CM2150 SN and ISBE CM2150 engines both require the retaining ring to keep certain parts in place, which is crucial for their performance and durability.

Group 3: ISBE4 CM850

The ISBE4 CM850 engine also utilizes the retaining ring to secure its components, contributing to the engine’s overall efficiency and reliability.

Group 4: QSB7 CM2880 B117

Finally, the QSB7 CM2880 B117 engine incorporates the retaining ring to maintain the stability of its parts, enhancing the engine’s operational lifespan.

Role of Part 5258019 Retaining Ring in Engine Systems

The Part 5258019 Retaining Ring is an essential component in various engine systems, ensuring the secure placement and operation of multiple parts. In the accessory drive gear system, the retaining ring holds the gear in place, allowing it to mesh correctly with other components and transfer power efficiently.

In the flywheel housing, the retaining ring plays a significant role by securing the flywheel, which is vital for maintaining engine balance and smooth operation. Similarly, in other housings, such as the rear gear housing, the retaining ring ensures that the rear gear remains fixed, preventing any unwanted movement that could lead to gear misalignment or failure.

For the idler gear, the retaining ring is used to keep the gear in its correct position, ensuring that it engages properly with the primary gears and maintains the intended gear ratio. In the intake manifold cover, the retaining ring helps to secure the cover, ensuring a proper seal and preventing any leaks that could affect engine performance.

When it comes to kits, such as those for the Repto module or fuel control systems, the retaining ring is often included to ensure that all components within the kit are held securely in place. This is particularly important in high-stress environments where vibrations and movements could otherwise dislodge parts, leading to potential system failures.

Overall, the Part 5258019 Retaining Ring is a fundamental component in maintaining the integrity and functionality of various engine systems, ensuring that all parts operate as intended 4.

Conclusion

The Cummins 5258019 Retaining Ring is a critical component in the maintenance and operation of commercial truck engines. Its role in securing various parts within the engine ensures the structural integrity and functionality of these components, contributing to the overall performance and reliability of the vehicle. Proper installation, regular maintenance, and understanding its compatibility with specific engine models are essential for maximizing the benefits of this Cummins part. By adhering to manufacturer guidelines and best practices, users can ensure the longevity and efficiency of their truck’s engine systems.

-

Crolla, David. Crolla Encyclopedia. Wiley, 2015.

↩ ↩ -

Bennett, Sean. Modern Diesel Technology Light Duty Diesels. Cengage Learning, 2012.

↩ ↩ -

Harrison, Matthew. Controlling Noise and Vibration in Road Vehicles. SAE International, 2004.

↩ ↩ -

Parikyan Ed, Tigran. Advances in Engine and Powertrain Research and Technology. Springer Nature, 2022.

↩ ↩ ↩ ↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.