This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

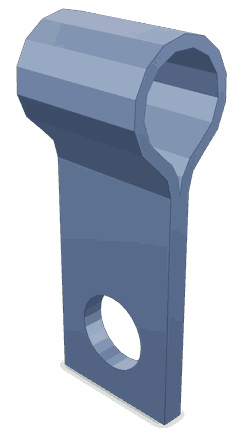

The 4982655 Retaining Clamp, manufactured by Cummins, is a component designed to enhance the maintenance and operation of commercial trucks. Cummins, a well-established name in the commercial truck industry, produces a range of parts and systems aimed at improving the efficiency, reliability, and safety of truck operations. This Cummins part plays a role in securing various parts within the truck’s mechanical systems 1.

Basic Concepts of Retaining Clamps

Retaining clamps are mechanical devices used to secure components in place within various systems. They function by applying pressure to hold parts together, preventing movement or separation that could lead to malfunction or failure. In mechanical systems, retaining clamps are important for maintaining the integrity and alignment of components, ensuring that systems operate smoothly and efficiently 2.

Purpose of the 4982655 Retaining Clamp

The 4982655 Retaining Clamp is specifically designed to secure components within the commercial truck’s engine and transmission systems. It plays a role in maintaining the proper alignment and connection of parts, which is vital for the efficient operation of the truck. By securing these components, the clamp helps to ensure that the truck operates reliably under various conditions 3.

Key Features

The 4982655 Retaining Clamp boasts several key features that enhance its functionality and durability. It is constructed from high-strength materials, ensuring it can withstand the rigors of commercial truck operation. The design includes precision-machined surfaces for a secure fit and long-lasting performance. Additionally, the clamp features an easy-to-use mechanism for quick installation and removal, facilitating maintenance procedures.

Benefits of Using the 4982655 Retaining Clamp

Incorporating the 4982655 Retaining Clamp into truck maintenance routines offers several advantages. It contributes to improved safety by securely holding components in place, reducing the risk of part failure during operation. The clamp also enhances reliability, ensuring that the truck’s mechanical systems function as intended. Furthermore, by maintaining component alignment and connection, the clamp supports efficient truck operation, potentially leading to fuel savings and reduced maintenance costs.

Installation Process

Installing the 4982655 Retaining Clamp requires careful attention to ensure proper fit and function. The process involves identifying the components to be secured, positioning the clamp around them, and then tightening it to the manufacturer’s specifications. Tools required may include a torque wrench for precise tightening. It is important to follow the installation instructions provided by Cummins to ensure the clamp is installed correctly.

Troubleshooting Common Issues

Common issues with the 4982655 Retaining Clamp may include improper fit, difficulty in tightening, or component misalignment. Troubleshooting these issues involves checking the clamp’s position and alignment, ensuring it is correctly installed according to the manufacturer’s guidelines. If the clamp does not fit securely or tighten properly, re-evaluating the installation process or consulting the manufacturer’s troubleshooting guide can help identify and resolve the problem.

Maintenance Tips

Regular maintenance of the 4982655 Retaining Clamp is key to its longevity and effective performance. This includes periodic checks for signs of wear or damage, ensuring it remains securely tightened, and cleaning any debris that may accumulate around the clamp. Following Cummins’ maintenance recommendations can help prevent issues and ensure the clamp continues to function as intended.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, emissions solutions, and related technologies. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s extensive product range and commitment to customer satisfaction make it a preferred choice for truck manufacturers and operators worldwide.

Role of the 4982655 Retaining Clamp in Engine Systems

The 4982655 retaining clamp is a component in ensuring the secure and efficient operation of various engine systems. Its primary function is to maintain the integrity and alignment of components, thereby contributing to the overall performance and reliability of the engine.

Integration with Gauge Systems

In gauge systems, the 4982655 retaining clamp plays a role by securing the gauge components in place. This ensures that the gauges remain accurately positioned, allowing for precise measurement and monitoring of engine parameters. The clamp helps in maintaining the structural stability of the gauge assembly, which is vital for consistent and reliable readings. This is particularly important in high-vibration environments where component displacement can lead to inaccurate data.

Application in Oil Level Monitoring

When integrated with oil level monitoring systems, the 4982655 retaining clamp ensures that the sensors and probes are held firmly in their designated positions. This is essential for accurate oil level readings, which are critical for maintaining proper lubrication and preventing engine damage. The clamp prevents the sensors from shifting or becoming misaligned, which could result in false readings and potential engine issues.

By securing these components, the retaining clamp contributes to the longevity and efficiency of the engine, ensuring that all monitoring systems function as intended.

Conclusion

The 4982655 Retaining Clamp by Cummins is a vital component in the maintenance and operation of commercial trucks. Its design and features ensure the secure attachment of various parts within the engine and transmission systems, contributing to the truck’s reliability and efficiency. Regular maintenance and proper installation of this part are crucial for its effective performance and the overall health of the truck’s mechanical systems.

-

Awari, G.K., Kumbhar, V.S., & Tirpude, R.B. (2011). Automotive Systems Principles and Practice. CRC Press.

↩ -

Gilles, T. (2020). Automotive Service: Inspection, Maintenance, Repair: 2nd Edition. Cengage Learning.

↩ -

Goodnight, N., & Van Gelder, K. (2018). Automotive Braking Systems. Jones & Bartlett Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.