This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4980101 Retaining Clamp is a vital component in commercial trucks, designed to enhance the efficiency and reliability of the vehicle’s mechanical systems. Understanding its role and significance is essential for maintaining and optimizing truck performance.

Basic Concepts of Retaining Clamps

Retaining clamps are mechanical devices that hold components in place within a system by applying pressure. This function is crucial for maintaining the integrity and performance of various mechanical systems 1.

Purpose of the 4980101 Retaining Clamp

This part secures specific components within a truck’s system, ensuring they remain in their designated positions. Its application varies across different truck models and systems, contributing to the smooth operation of the vehicle.

Key Features

The 4980101 is characterized by its robust material composition, typically featuring high-strength alloys that provide durability and resistance to wear. Its design includes elements that enhance its grip and stability, ensuring effective retention of components. Unique characteristics may include adjustable features for a custom fit or corrosion-resistant coatings for longevity 2.

Benefits of Using the 4980101 Retaining Clamp

Incorporating this Cummins part into truck maintenance and operation offers several advantages. Its durable construction ensures long-term use, while its efficient design contributes to the overall reliability of the truck’s systems. The clamp’s ability to securely hold components in place reduces the risk of mechanical failure, enhancing safety and performance 3.

Installation Process

Installing the 4980101 requires careful attention to ensure proper fit and function. The process involves positioning the clamp around the component it is designed to secure, followed by tightening to the manufacturer’s specifications. Tools such as wrenches may be required, and it is important to follow the installation instructions provided by Cummins to ensure correct application.

Common Issues and Troubleshooting

Frequent problems with the 4980101 may include loosening over time or damage due to wear and tear. Troubleshooting involves inspecting the clamp for signs of wear, ensuring it is correctly installed, and tightening or replacing it as necessary. Regular checks can help identify issues before they lead to more significant problems.

Maintenance Tips

To ensure the longevity and optimal performance of the 4980101, regular maintenance is recommended. This includes periodic inspection for signs of wear or damage, cleaning to remove any debris that may affect its function, and ensuring it remains securely tightened. Following these maintenance routines can help prevent issues and extend the life of the clamp.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. Its product range includes a variety of components and systems designed to enhance the performance and reliability of commercial vehicles.

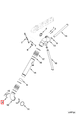

Cummins Engine Part 4980101: Retaining Clamp Application

The Cummins part number 4980101, identified as a Retaining Clamp, is a critical component in the assembly of several Cummins diesel engines. This part is designed to secure various engine parts in place, ensuring the integrity and performance of the engine. Here is how the Retaining Clamp fits within the specified engines:

-

QSB5.9 CM850 and QSC8.3 CM850 (CM2850): In these engines, the Retaining Clamp 4980101 is used to secure components such as fuel injectors and other critical parts that require precise alignment and stability. Its role is vital in maintaining the operational efficiency and longevity of these engines.

-

QSB6.7 M CM2250: For the QSB6.7 M CM2250 engine, the Retaining Clamp 4980101 is employed to hold components in place, ensuring that parts such as the turbocharger and other related assemblies are securely fastened. This helps in maintaining the engine’s performance under various operating conditions.

-

QSM11 CM570: In the QSM11 CM570 engine, the Retaining Clamp 4980101 is used to secure parts that are crucial for the engine’s operation. Its application in this engine ensures that all components are held firmly, contributing to the overall reliability and efficiency of the engine.

The use of the Retaining Clamp 4980101 across these engines highlights its importance in maintaining the structural integrity and performance of Cummins diesel engines. Its design and material ensure that it can withstand the rigors of engine operation, providing a reliable solution for securing various components.

Role of Part 4980101 Retaining Clamp in Various Engine Systems

The 4980101 Retaining Clamp is a critical component in ensuring the secure and efficient operation of various engine systems. Its primary function is to maintain the integrity of connections within these systems, preventing leaks and ensuring optimal performance.

Connection Stability

In any engine system, the stability of connections is paramount. The 4980101 Retaining Clamp plays a significant role in securing these connections, particularly in high-stress areas where vibrations and thermal expansion can lead to loosening. By providing a firm grip, it ensures that components remain aligned and sealed, which is vital for the consistent operation of the engine 4.

Exhaust Outlet Management

The exhaust outlet is a critical area where the 4980101 Retaining Clamp demonstrates its effectiveness. It secures the exhaust components, ensuring that the flow of exhaust gases is directed correctly without any leaks. This not only enhances the efficiency of the engine but also reduces the risk of harmful emissions escaping into the environment.

Plumbing Systems

In marine propulsion systems, the 4980101 Retaining Clamp is often used in plumbing applications. It ensures that coolant, fuel, and other fluids are transported efficiently without any risk of leakage. This is particularly important in marine environments where the integrity of fluid systems can significantly impact the performance and safety of the vessel.

Exhaust Outlet Connection

The connection between the exhaust outlet and the manifold is another area where the 4980101 Retaining Clamp is invaluable. It ensures a tight seal, which is essential for maintaining the backpressure required for efficient engine operation. This connection is subject to high temperatures and pressures, making the reliability of the clamp a key factor in the overall performance of the engine.

System Integration

Overall, the 4980101 Retaining Clamp contributes to the seamless integration of various components within an engine system. Whether it’s securing pipes, manifolds, or other critical parts, its role in maintaining the structural and functional integrity of the system cannot be overstated. This ensures that all components work in harmony, leading to enhanced engine performance and reliability.

Conclusion

The Cummins 4980101 Retaining Clamp is a crucial component in the maintenance and operation of commercial trucks and Cummins diesel engines. Its robust design, durable materials, and efficient functionality contribute to the overall reliability and performance of the vehicle. Regular maintenance and proper installation are key to ensuring the longevity and effectiveness of this part.

-

Ling, Frederick F. The Automotive Body. Springer Science, 2011.

↩ -

Composite Materials Handbook Volume 4 Metal Matrix Composites. SAE International, 2013.

↩ -

Mananathan, R. Automobile Wheel Alignment and Wheel Balancing. SAE International, 2022.

↩ -

Asef, Pedram, Sanjeevikumar Padmanaban, and Andrew Lapthorn. Modern Automotive Electrical Systems. Wiley, 2022.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.