This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4324176 Retaining Clamp, manufactured by Cummins, is a component designed for use in commercial trucks. Retaining clamps play a role in heavy-duty truck maintenance and operation by securing various components in place, ensuring the truck’s systems function correctly and safely. This overview provides insights into the 4324176 Retaining Clamp, its purpose, features, and benefits, along with installation, maintenance, and safety considerations.

Basic Concepts of Retaining Clamps

Retaining clamps are mechanical devices used to hold components securely in place within a system. They function by applying pressure to the components they are designed to secure, preventing movement and ensuring stability. These clamps are commonly manufactured from materials such as steel, aluminum, or composite materials, chosen for their strength, durability, and resistance to environmental factors. The material selection impacts the clamp’s performance, longevity, and suitability for specific applications 1.

Purpose of the 4324176 Retaining Clamp

The 4324176 Retaining Clamp serves a specific role in truck operations by securing components within the truck’s systems. It ensures that parts remain in their designated positions, which is vital for the reliable and safe operation of the vehicle. By holding components firmly in place, the clamp contributes to the overall stability and functionality of the truck’s systems, playing a part in maintaining the vehicle’s performance and safety standards 2.

Key Features

The 4324176 Retaining Clamp is characterized by several key features that enhance its performance and durability. Its design includes elements that allow for a secure fit, ensuring that components are held firmly without the risk of slippage or movement. The material composition of the clamp is selected for its strength and resistance to wear, contributing to the clamp’s longevity and effectiveness in truck applications. Unique attributes, such as corrosion resistance or ease of installation, further enhance its suitability for use in commercial trucks 3.

Benefits

Using the 4324176 Retaining Clamp offers several benefits, including improved component security, enhanced system reliability, and potential cost savings through reduced maintenance needs. By securely holding components in place, the clamp helps prevent issues that could arise from component movement, such as wear, damage, or failure. This contributes to the truck’s overall performance and operational efficiency, potentially reducing downtime and maintenance costs.

Installation Process

Proper installation of the 4324176 Retaining Clamp involves several steps to ensure a secure and correct fit. The process may require specific tools or additional components, depending on the application. Tips for installation include verifying the clamp’s compatibility with the components it will secure, ensuring the surfaces are clean and free of debris, and applying the necessary pressure to achieve a secure fit. Following these guidelines helps maximize the clamp’s effectiveness and longevity.

Troubleshooting and Maintenance

Common issues with the 4324176 Retaining Clamp may include loosening over time, damage from environmental factors, or wear from use. Troubleshooting steps involve inspecting the clamp for signs of damage or wear, ensuring it is securely fastened, and addressing any issues promptly to prevent further complications. Maintenance tips include regular inspection of the clamp and its secured components, cleaning the clamp and surrounding areas, and replacing the clamp if it shows signs of significant wear or damage.

Compatibility and Applications

The 4324176 Retaining Clamp is designed for use in specific types of trucks and models, with compatibility determined by the clamp’s design and the requirements of the truck’s systems. Understanding the clamp’s applications and how to determine compatibility with other truck systems and components is important for ensuring optimal performance and reliability.

Safety Considerations

When working with the 4324176 Retaining Clamp, it is important to follow safety guidelines to protect both the worker and the equipment. This includes proper handling, installation, and maintenance practices, as well as recommendations for personal protective equipment (PPE) and maintaining a safe work environment. Adhering to these safety considerations helps prevent accidents and ensures the clamp’s effective and safe use.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its commitment to quality and innovation in truck component manufacturing. With a rich history and a focus on advancing technology and efficiency, Cummins plays a significant role in the industry, providing reliable and high-performance components for commercial vehicles.

Cummins Part 4324176: Retaining Clamp Compatibility with QSK95 Engines

The Cummins part 4324176, a Retaining Clamp, is designed to fit seamlessly with the QSK95 series engines, specifically the QSK95 CM2350 K111 and QSK95 CM2350 K113 models. This retaining clamp is a component in ensuring the integrity and functionality of the engine’s various systems.

For the QSK95 CM2350 K111 and QSK95 CM2350 K113 engines, the retaining clamp is integral to the engine’s assembly, providing support and stability. It is engineered to maintain the alignment and secure the positioning of engine components, ensuring optimal performance and longevity.

In both the QSK95 CM2350 K111 and QSK95 CM2350 K113 engines, the retaining clamp is strategically placed to withstand the operational stresses and environmental conditions these engines encounter. This ensures that the clamp remains effective in its role, contributing to the overall reliability of the engine.

Given the specific design and engineering of these engines, the retaining clamp is a part that fits precisely, facilitating ease of installation and maintenance. Its compatibility with both the QSK95 CM2350 K111 and QSK95 CM2350 K113 models underscores its versatility and importance in maintaining the structural integrity of these engines.

Role of Part 4324176 Retaining Clamp in Engine Systems

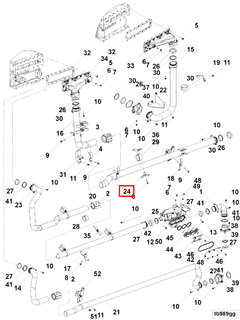

The 4324176 Retaining Clamp is a component in various engine systems, ensuring the secure attachment and stability of multiple parts. Its application spans across several key systems, enhancing overall engine performance and reliability.

Auxiliary Cooling System

In the auxiliary cooling system, the 4324176 Retaining Clamp is utilized to hold components such as hoses, fittings, and sensors in place. This ensures that the cooling fluid flows efficiently without any leaks, maintaining optimal engine temperature. The clamp’s reliable hold prevents vibrations and movements that could otherwise disrupt the cooling process.

Service Kit

When included in a service kit, the 4324176 Retaining Clamp plays a role in facilitating routine maintenance and repairs. It allows for the easy replacement of worn-out parts by providing a secure fit for new components. This ensures that the engine system remains in top condition, reducing downtime and enhancing operational efficiency.

General System Integration

Across various engine systems, the 4324176 Retaining Clamp is employed to secure critical connections and attachments. Whether it’s holding pipes in the fuel system, stabilizing electrical connections, or ensuring the integrity of emission control components, this clamp contributes to the seamless operation of the engine. Its versatile application underscores its importance in maintaining the structural and functional integrity of engine systems.

Conclusion

The 4324176 Retaining Clamp by Cummins is a vital component in the maintenance and operation of commercial trucks, particularly in ensuring the secure attachment and stability of engine components. Its design, featuring materials chosen for strength and durability, plays a significant role in the reliability and efficiency of truck systems. Proper installation, regular maintenance, and adherence to safety guidelines are essential for maximizing the effectiveness and longevity of this part. Understanding its compatibility with specific truck models and engine systems, such as the QSK95 series, highlights its importance in maintaining the structural integrity and performance of commercial vehicles.

-

Heywood, John. Internal Combustion Engine Fundamentals. McGraw-Hill Education, 2019.

↩ -

Reif, Konrad Ed. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Mom, Gijs. The Evolution of Automotive Engineering: A Handbook. SAE International, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.