This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

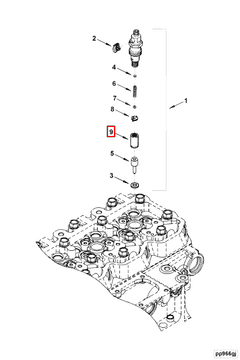

The Injector Nozzle Retainer 3915120, a component designed by Cummins, plays a role in the fuel injection system of heavy-duty trucks. Its purpose is to secure the injector nozzle in place, ensuring proper alignment and sealing within the engine’s fuel injection system. This Cummins part contributes to the overall efficiency and performance of the engine by maintaining the integrity of the fuel injection process.

Function and Operation

This part operates by holding the injector nozzle firmly in position within the fuel injection system. It interacts with other components such as the injector body and the cylinder head. The retainer ensures that the nozzle is correctly aligned, which is vital for the precise delivery of fuel into the combustion chamber. This precise alignment helps in achieving optimal fuel atomization and combustion efficiency.

Key Features

The Injector Nozzle Retainer 3915120 is characterized by its durable design and the use of high-quality materials. It is engineered to withstand the high pressures and temperatures present in the fuel injection system of heavy-duty engines. The precision machining of this component ensures a tight seal and proper fit, which are critical for the efficient operation of the fuel injection system.

Benefits

The use of the Injector Nozzle Retainer 3915120 offers several advantages. It contributes to improved fuel efficiency by ensuring that fuel is delivered accurately and consistently. This precise fuel delivery also helps in reducing emissions, as it allows for more complete combustion of the fuel. Additionally, the retainer enhances engine performance by maintaining the integrity of the fuel injection process, leading to smoother operation and increased reliability.

Installation and Maintenance

Proper installation of the Injector Nozzle Retainer involves following specific torque specifications and alignment procedures to ensure it is securely fastened and correctly positioned. Regular maintenance, including inspection for wear or damage, is recommended to ensure the longevity and optimal performance of the component. Cleaning and, if necessary, replacing the retainer can help prevent issues related to fuel injection system performance.

Troubleshooting Common Issues

Typical problems associated with Injector Nozzle Retainers may include leaks or misfires. These issues can often be traced back to improper installation, wear, or damage to the retainer. Diagnostic procedures may involve inspecting the retainer for signs of wear, ensuring it is correctly installed, and checking for any leaks in the fuel injection system. Repair or replacement of the retainer may be necessary to resolve these issues.

Manufacturer Overview

Cummins is a well-established manufacturer in the automotive industry, known for its commitment to innovation and quality. The company offers a wide range of products designed for heavy-duty applications, including engines, powertrains, and components like the Injector Nozzle Retainer 3915120. Cummins’ focus on research and development ensures that its products meet the demanding requirements of modern heavy-duty trucks.

Conclusion

This overview provides a comprehensive understanding of the Injector Nozzle Retainer 3915120, its function within the fuel injection system, and the benefits it offers to heavy-duty truck engines. Proper installation, maintenance, and troubleshooting are key to ensuring the component’s effectiveness and longevity.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.