This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3636637 Retaining Clamp is a component manufactured by Cummins, a well-established name in the commercial truck industry. This retaining clamp is designed for use in commercial trucks, where it plays a role in securing various components, ensuring they remain in place under operational conditions.

Basic Concepts of Retaining Clamps

Retaining clamps are mechanical devices used to hold components firmly in place. They are commonly employed in various systems to prevent movement and ensure stability. These clamps function by applying consistent pressure to the components they secure, which helps maintain alignment and integrity within the system 1.

Purpose of the 3636637 Retaining Clamp

The 3636637 Retaining Clamp is specifically designed to secure components within a truck’s system. It interacts with various parts, ensuring they remain fixed during operation. This clamp is particularly useful in environments where vibrations and movements are common, as it helps maintain the structural integrity of the components it holds 2.

Key Features

The 3636637 Retaining Clamp boasts several key features that enhance its functionality. It is constructed from durable materials, ensuring longevity and resistance to wear. The design includes elements that allow for easy installation and adjustment, providing flexibility in various applications. Additionally, the clamp features a robust mechanism that ensures a secure fit, reducing the risk of component displacement 3.

Benefits

The advantages of using the 3636637 Retaining Clamp include improved reliability and efficiency in truck operations. By securely holding components in place, it helps prevent issues that could arise from component movement. This can lead to reduced maintenance needs and operational downtime, offering cost-saving benefits for fleet operators.

Installation Process

Installing the 3636637 Retaining Clamp involves several steps to ensure a secure fit. Begin by identifying the components that require clamping. Use the appropriate tools to position the clamp around these components. Adjust the clamp to apply the necessary pressure, ensuring it holds the components firmly without causing damage. Follow best practices for tightening to achieve optimal performance.

Troubleshooting Common Issues

Common problems with retaining clamps may include improper fitting or component displacement. These issues can often be traced back to incorrect installation or wear and tear. To address these problems, inspect the clamp for signs of damage or misalignment. Adjust the clamp as needed, or replace it if necessary, to restore secure component holding.

Maintenance Tips

Regular maintenance of the 3636637 Retaining Clamp is important for ensuring its longevity and consistent performance. Inspect the clamp at regular intervals for signs of wear or damage. Clean the clamp and surrounding components to remove any debris that could affect its operation. Following these maintenance practices can help prevent issues and ensure the clamp continues to function effectively.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its wide range of products and strong reputation. Founded with a commitment to innovation and quality, Cummins has established itself as a trusted provider of engine and power generation equipment. The company’s extensive product line includes components like the 3636637 Retaining Clamp, which are designed to meet the demanding requirements of commercial truck operations.

Cummins Part 3636637 Retaining Clamp Compatibility

The Cummins part 3636637 Retaining Clamp is designed to fit seamlessly with a range of Cummins engines, ensuring secure fastening and reliable performance. This retaining clamp is compatible with the following engines:

QSK38 Series Engines

- QSK38 CM2150 MCRS

- QSK38 CM850 MCRS

The QSK38 series engines, both the CM2150 MCRS and CM850 MCRS variants, are designed for heavy-duty applications. The part 3636637 Retaining Clamp is engineered to provide the necessary support and stability in these demanding environments.

QSK50 Series Engines

- QSK50 CM2150 K107

- QSK50 CM2150 MCRS

- QSK50 CM2350 K108

The QSK50 series engines, including the CM2150 K107, CM2150 MCRS, and CM2350 K108, are built for high-performance applications. The part 3636637 Retaining Clamp is specifically designed to meet the rigorous demands of these engines, ensuring that all components are securely fastened and operating efficiently.

By using the part 3636637 Retaining Clamp, users can ensure that their Cummins engines maintain optimal performance and reliability across various applications.

Understanding the Role of Part 3636637 Retaining Clamp in Engine Systems

The part 3636637 retaining clamp is an essential component in ensuring the secure and efficient operation of various engine systems. Its application spans across multiple critical areas, contributing to the overall performance and reliability of the engine.

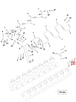

Integration with Camshaft and Gear

In the camshaft and gear assembly, the retaining clamp plays a significant role in maintaining the precise alignment and secure fitting of the camshaft to the gear. This ensures that the camshaft operates smoothly, reducing the risk of misalignment that could lead to increased wear or failure. The clamp’s ability to hold components in place under varying operational stresses is vital for consistent engine performance.

Securing Connecting Rod and Piston

The connecting rod and piston assembly is another area where the retaining clamp is instrumental. By securely holding the connecting rod to the piston, the clamp helps maintain the integrity of the assembly during the engine’s power strokes. This secure fit is essential for efficient power transfer from the piston to the crankshaft, directly influencing the engine’s overall performance.

Ensuring Integrity in Fuel Supply Plumbing

In the fuel supply plumbing system, the retaining clamp is used to secure fuel lines and fittings. This is particularly important in high-performance engines where fuel delivery must be precise and reliable. The clamp ensures that there are no leaks or disconnections in the fuel lines, which could lead to inefficient fuel delivery or even dangerous fuel spills.

Role in Performance Parts

For performance parts, the retaining clamp is often utilized to secure aftermarket components that are designed to enhance engine performance. Whether it’s a high-flow fuel injector or a custom fuel line, the clamp ensures that these parts are held firmly in place, allowing them to function as intended without the risk of detachment or misalignment.

Application in Plumbing and Fuel Systems

In the broader context of engine plumbing and fuel systems, the retaining clamp is a versatile component. It is used to secure various plumbing connections, from fuel injectors to fuel filters. This ensures that the fuel system remains intact and functions efficiently, which is essential for optimal engine performance.

Contribution to Overall Engine Performance

Ultimately, the retaining clamp’s role in securing and aligning various engine components contributes significantly to the engine’s performance. By ensuring that all parts are held in place and functioning correctly, the clamp helps maintain the engine’s efficiency, reliability, and longevity.

Conclusion

The 3636637 Retaining Clamp is a vital component in the operation of Cummins engines, ensuring the secure and efficient functioning of various engine systems. Its robust design, ease of installation, and compatibility with a range of Cummins engines make it an indispensable part for maintaining engine performance and reliability.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.