3636624

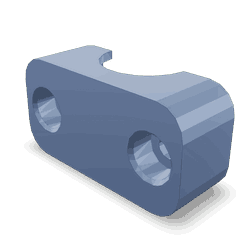

Retaining Clamp

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3636624 Retaining Clamp is a component designed for use in heavy-duty truck applications. Its purpose is to secure various parts within the truck’s engine system, ensuring they remain in place under operational conditions. This clamp is significant due to its role in maintaining the integrity and efficiency of the truck’s components.

Purpose and Function

The 3636624 Retaining Clamp serves to hold specific parts in position within the truck’s engine system. It is applied in scenarios where components need to be firmly secured to prevent movement or detachment during operation. This clamp supports the reliable functioning of the engine by ensuring that critical parts remain correctly aligned and connected 1.

Key Features

The design of the 3636624 Retaining Clamp incorporates materials and dimensions tailored for heavy-duty applications. Constructed from durable materials, it is built to withstand the rigors of truck engine environments. Its design includes features that enhance its grip and stability, ensuring a secure hold on the components it is meant to retain 2.

Benefits

Utilizing the 3636624 Retaining Clamp offers several advantages. It contributes to the overall reliability of the truck’s engine system by securely holding parts in place. The clamp is designed for ease of installation, reducing downtime during maintenance procedures. Its durability ensures long-term performance under various operating conditions, making it a valuable component for heavy-duty trucks.

Installation Process

Installing the 3636624 Retaining Clamp requires following a series of steps to ensure proper fitting. The process involves identifying the correct location for the clamp, using the appropriate tools to secure it in place, and verifying that it holds the component firmly without causing damage. Best practices include checking the clamp’s alignment and tension to ensure optimal performance.

Maintenance and Care

Regular maintenance of the 3636624 Retaining Clamp is recommended to ensure continued optimal performance. This includes cleaning the clamp to remove any debris or contaminants, checking for signs of wear or damage, and replacing it if necessary. Adhering to these maintenance practices helps maintain the clamp’s effectiveness and the overall efficiency of the truck’s engine system.

Troubleshooting Common Issues

Common issues with the 3636624 Retaining Clamp may include loosening over time or damage due to wear. Addressing these problems involves inspecting the clamp for any signs of deterioration, tightening it if it has loosened, or replacing it if it is damaged. Prompt attention to these issues helps prevent more significant problems within the engine system.

Safety Considerations

When working with the 3636624 Retaining Clamp, it is important to observe safety guidelines and precautions. This includes ensuring the engine is off and cooled down before beginning any work, using the correct tools for installation and maintenance, and following all manufacturer recommendations for handling and use. These safety measures help protect both the technician and the equipment.

Cummins Overview

Cummins Inc. is a leading manufacturer of diesel engines, known for its commitment to quality and innovation in the heavy-duty truck industry. With a history of producing reliable and efficient engine components, Cummins has established a reputation for excellence. The company’s focus on advancing technology and meeting the needs of its customers underscores its position as a trusted provider of heavy-duty truck parts.

Role of Part 3636624 Retaining Clamp in Engine Systems

Integration with the Oil Level Gauge

The 3636624 retaining clamp is instrumental in securing the oil level gauge within the engine system. By firmly holding the gauge in place, it ensures accurate readings of the oil level, which is essential for maintaining optimal engine performance and preventing potential damage from oil starvation or overfilling 1.

Ensuring Stability at the Location

At the designated location within the engine, the retaining clamp plays a significant role in maintaining the structural integrity of the oil level gauge. This stability is vital for consistent and reliable operation, as any movement or misalignment could lead to incorrect readings and subsequent engine issues.

Enhanced System Reliability

The use of the retaining clamp enhances the overall reliability of the engine system. By securing the oil level gauge, it contributes to a more stable and dependable engine environment, which is fundamental for both performance and longevity of the engine components 2.

Conclusion

The 3636624 Retaining Clamp by Cummins is a vital component in heavy-duty truck engine systems, ensuring the secure placement and stability of critical parts. Its design and functionality contribute to the reliability and efficiency of the engine, making it an essential part for maintaining optimal performance in demanding operational conditions.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.