3092793

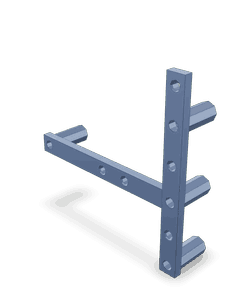

Retaining Brace Bracket

Cummins®

AVAILABLE

2 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Retaining Brace Bracket, part number 3092793, manufactured by Cummins, is a component designed for heavy-duty trucks. Cummins, a well-established name in the automotive industry, is known for its high-quality and reliable parts. This bracket is significant in the context of heavy-duty truck components due to its role in enhancing the structural integrity and operational efficiency of the vehicle.

Purpose and Function

The Retaining Brace Bracket serves a specific purpose in heavy-duty trucks. It is designed to provide additional support and stability to various components within the truck’s structure. By doing so, it contributes to the overall structural integrity of the vehicle. Furthermore, the bracket plays a role in maintaining the alignment and positioning of certain parts, which is vital for the truck’s operational efficiency 1.

Key Features

The Retaining Brace Bracket is characterized by several key features that enhance its performance and durability. Its design is engineered to withstand the rigors of heavy-duty use, incorporating materials that offer strength and resistance to wear and tear. Unique characteristics of the bracket may include specific mounting points or a design that allows for easy installation and adjustment, ensuring it meets the demands of its application 2.

Benefits

The installation of the Retaining Brace Bracket offers several benefits. It contributes to improved stability of the truck’s components, which can lead to enhanced safety during operation. Additionally, by maintaining the proper alignment and support of parts, the bracket can increase the longevity of these components, reducing the need for frequent replacements or repairs 3.

Installation Process

Proper installation of the Retaining Brace Bracket is crucial for its effectiveness. The process involves securing the bracket in its designated location using the appropriate tools and, if necessary, additional components. Detailed instructions should be followed to ensure that the bracket is installed correctly, providing the intended support and stability.

Maintenance and Troubleshooting

Regular maintenance practices are recommended to ensure the longevity and effectiveness of the Retaining Brace Bracket. This may include periodic inspections for signs of wear or damage and ensuring that all mounting points are secure. Common issues that may arise with the bracket can often be addressed through troubleshooting, such as tightening loose components or replacing worn parts.

Compatibility and Usage

The Retaining Brace Bracket is designed for use with specific types of trucks and engine models. Its application may vary depending on the operational scenario, with guidelines available to ensure it is used correctly in each situation. Understanding the compatibility and proper usage of the bracket is important for maximizing its benefits.

Safety Considerations

When installing, maintaining, or troubleshooting the Retaining Brace Bracket, it is important to observe certain safety guidelines and precautions. This includes ensuring that the vehicle is properly supported during installation and that all work is performed in a safe environment. Following these safety considerations helps protect both the individual performing the work and the integrity of the vehicle.

Cummins: A Brief Overview

Cummins Inc. is a leader in the automotive industry, with a history of innovation and quality in the production of engines and components. The company’s product range includes a variety of parts designed for heavy-duty trucks, showcasing Cummins’ commitment to enhancing the performance and reliability of these vehicles. Cummins’ reputation in the industry is built on its contributions to the development of advanced and durable truck components.

Cummins Retaining Brace Bracket 3092793 Compatibility

The Cummins Retaining Brace Bracket part number 3092793 is designed to fit seamlessly with a range of Cummins engines, ensuring structural integrity and operational efficiency. This part is crucial for maintaining the alignment and stability of engine components, particularly in high-stress environments.

QST30 CM552 Engines

The Cummins Retaining Brace Bracket 3092793 is specifically engineered to integrate with the QST30 CM552 engines. This bracket plays a vital role in securing the engine’s internal components, ensuring that they remain in place during operation. Its precise fit and robust construction make it an essential part for maintaining the engine’s performance and longevity.

Grouping of Compatible Engines

While the primary focus here is on the QST30 CM552 engines, the Cummins Retaining Brace Bracket 3092793 is also compatible with other Cummins engine models that share similar design and structural requirements. This compatibility extends to various engine groups within the Cummins lineup, ensuring that the bracket can be used across multiple applications without compromising its functionality.

The bracket’s design allows it to fit snugly within the engine’s framework, providing the necessary support and stability. This ensures that the engine operates smoothly and efficiently, reducing the risk of mechanical failure and extending the engine’s overall lifespan.

Role of Part 3092793 Retaining Brace Bracket in Engine Systems

The 3092793 retaining brace bracket is an essential component in the assembly and stabilization of various engine systems. It provides structural support and ensures the secure positioning of key components, thereby contributing to the overall efficiency and reliability of the engine.

Integration with the Monitor

In engine systems equipped with a monitor, the 3092793 retaining brace bracket plays a significant role. It secures the monitor in place, ensuring that it remains stable during engine operation. This stability is vital for accurate readings and consistent performance. The bracket also facilitates easy access for maintenance and calibration, enhancing the monitor’s functionality and longevity.

Compatibility with Electronic Engine Components

For electronic engine systems, the 3092793 retaining brace bracket is instrumental in maintaining the integrity of the electronic components. It supports sensors, control units, and wiring harnesses, ensuring they are properly aligned and protected from vibrations and external impacts. This support is essential for the precise operation of electronic systems, which rely on stable and secure component placement to function correctly.

Enhanced System Performance

By providing a robust framework for these components, the 3092793 retaining brace bracket contributes to the enhanced performance of the engine system. It ensures that all parts are held in optimal positions, reducing the risk of malfunctions and improving the overall reliability of the engine. This is particularly important in high-performance engines where precision and stability are paramount.

Facilitation of Maintenance

The design of the 3092793 retaining brace bracket also aids in the maintenance of engine systems. Its secure hold on components allows for easier disassembly and reassembly, which is crucial during routine checks and repairs. This feature not only saves time but also reduces the potential for errors during maintenance procedures.

Conclusion

In summary, the 3092793 retaining brace bracket is a vital component in the assembly and operation of engine systems, particularly when integrated with monitors and electronic engine components. Its role in providing structural support, ensuring component stability, and facilitating maintenance underscores its importance in the efficient and reliable performance of engine systems.

-

Goodnight, Nicholas, and Kirk Van Gelder. Automotive Braking Systems. Jones & Bartlett Learning, 2018.

↩ -

Klyde, Michael, and Kirk VanGelder. Advanced Automotive Electricity and Electronics. Jones Bartlett Learning, 2010.

↩ -

Lakshminarayanan, P. A., and Avinash Kumar. Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature, 2020.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.