This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Injector Link Retainer 3072486, a component manufactured by Cummins, plays a significant role in the fuel injection system of heavy-duty truck engines. Cummins, a renowned name in the automotive industry, is particularly known for its diesel engines and components. This part ensures efficient and reliable operation within the fuel injection system.

Function and Operation

The Injector Link Retainer operates by securing the injector link, which connects the fuel injector to the engine’s camshaft. This connection is essential for the precise timing of fuel injection, contributing to optimal engine performance. The retainer ensures that the injector link remains in the correct position, allowing for consistent and accurate fuel delivery 1.

Purpose of the Injector Link Retainer

The primary function of the Injector Link Retainer is to maintain the integrity of the fuel injection timing. By securing the injector link, it enhances the overall efficiency of the fuel injection process. This contributes to better engine performance, including smoother operation and potentially improved fuel economy 2.

Key Features

The Injector Link Retainer 3072486 is designed with features that enhance its functionality and reliability. These include robust construction to withstand high pressures and temperatures, precise engineering for accurate injector link positioning, and compatibility with a range of Cummins engine models.

Benefits

Using the Injector Link Retainer 3072486 offers several advantages, including improved fuel efficiency due to more accurate fuel injection timing, enhanced engine performance through consistent injector operation, and increased durability thanks to its sturdy construction. These benefits contribute to the overall reliability and longevity of the engine 3.

Installation and Compatibility

Proper installation of the Injector Link Retainer involves securing it to the engine block and ensuring it is correctly aligned with the injector link and camshaft. It is compatible with various Cummins engine models, making it a versatile component for fleet management and maintenance.

Maintenance and Troubleshooting

Regular maintenance of the Injector Link Retainer includes inspecting it for signs of wear or damage, cleaning it to remove any buildup that could affect its operation, and ensuring all connections are secure. Common troubleshooting tips involve checking for proper alignment and ensuring there are no obstructions that could interfere with its function.

Common Failure Modes

Typical failure modes for the Injector Link Retainer may include wear from continuous use, damage from high engine temperatures, or issues arising from improper installation. Addressing these involves inspecting the component for signs of wear, ensuring it is correctly installed, and replacing it if necessary to maintain engine performance.

Upgrades and Modifications

Possible upgrades or modifications to the Injector Link Retainer could involve enhancing its material properties for increased durability or modifying its design to improve compatibility with newer engine models. These modifications aim to further optimize engine performance and reliability.

Cummins Corporation

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a strong reputation in the automotive industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction, particularly in the realm of diesel engines and components.

Compatibility with Cummins Engines

The Injector Link Retainer, part number 3072486, is compatible with various Cummins engine models, including:

- ISM Series Engines: ISM CM570, ISM CM570/870, ISM CM876, ISM11 CM876 SN

- L10 and M11 Series Engines: L10 CELECT, M11 CELECT, M11 CELECT PLUS

- N14 Series Engines: N14 CELECT PLUS

- QSM11 and QSNT14 Series Engines: QSM11 CM570, QSM11 CM876, QSNT14 CM876 N102

- QSN14 Series Engine: QSN14 CM876 N103

By ensuring that the injector links are held firmly in place, the Injector Link Retainer contributes to the overall reliability and efficiency of these Cummins engines.

Interaction with Key Engine Components

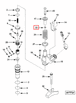

The Injector Link Retainer interacts with several key engine components:

- Injector Plunger Link: Ensures the injector plunger link remains in the correct operational position.

- Injectors: Contributes to the performance of the injectors by stabilizing the injector plunger link.

- Cylinder Head: Supports the structural stability of the injector components.

- Engine Piston Kit and Connecting Rod: Influences the combustion process through timely and accurate fuel injection.

- Camshaft and Campaign Kit: Aligns with the camshaft’s function in controlling the valve timing.

Contribution to Engine Performance

The Injector Link Retainer is a significant contributor to engine performance. Its role in securing the injector plunger link ensures that the fuel injection process is both timely and accurate. This precision is essential for maximizing engine efficiency, power output, and overall performance. Additionally, by maintaining the structural integrity of the injector components, the retainer supports the longevity and reliability of the engine system.

Conclusion

The Injector Link Retainer 3072486 by Cummins is a critical component in the fuel injection system of heavy-duty truck engines. Its role in ensuring precise fuel injection timing and maintaining the structural integrity of injector components contributes significantly to engine performance, efficiency, and reliability. Proper installation, regular maintenance, and understanding its interaction with other engine components are essential for maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.