3068768

Retaining Ring

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3068768 Retaining Ring is a component designed for use in commercial trucks. Its purpose is to secure various mechanical parts in place, ensuring they function correctly within the truck’s systems. This Cummins part is specifically engineered to meet the demands of heavy-duty applications, providing stability and reliability in the operation of commercial vehicles.

Basic Concepts of Retaining Rings

Retaining rings, also known as circlips, are mechanical fasteners used to prevent components from moving along a shaft or within a housing. They operate by fitting into a groove and exerting pressure against the walls of that groove, thereby securing the component in place. Retaining rings are essential in many mechanical systems for their simplicity, effectiveness, and ease of installation and removal 1.

Role of the 3068768 Retaining Ring in Truck Operation

In the context of truck operation, the Cummins 3068768 Retaining Ring plays a specific role in securing components within the truck’s mechanical systems. It is typically placed in grooves on shafts or within housings to hold bearings, gears, or other parts in position. This ensures that these components remain fixed during operation, contributing to the smooth and efficient functioning of the truck’s mechanical systems.

Key Features

The Cummins 3068768 Retaining Ring is characterized by several key features that enhance its performance and durability. It is made from high-quality materials, designed to withstand the rigors of heavy-duty use. The ring’s design specifications, including its size, shape, and the precision of its fit, are tailored to ensure optimal functionality in its intended applications. Additionally, any unique attributes, such as special coatings or treatments, further contribute to its performance and longevity.

Benefits

The use of the Cummins 3068768 Retaining Ring offers several benefits. It provides improved mechanical stability by securely holding components in place, which is vital for the reliable operation of truck systems. Enhanced performance is another advantage, as the secure fit of components can lead to more efficient operation of the mechanical systems. Moreover, the durability of the retaining ring contributes to the longevity of the components it secures, reducing the need for frequent replacements and maintenance 2.

Troubleshooting and Maintenance

Common issues associated with retaining rings include wear, deformation, or displacement, which can lead to component failure or inefficient operation. Troubleshooting these problems involves inspecting the ring for signs of damage or improper fit and addressing any issues promptly. Maintenance practices for the Cummins 3068768 Retaining Ring include regular inspection during routine maintenance checks, ensuring it remains in good condition and properly seated. Replacing the ring when signs of wear or damage are detected is also a key maintenance practice to ensure the longevity and proper function of the mechanical systems it supports 3.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable, high-performance engines and components. The company’s product range includes a wide array of engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial and industrial applications. Cummins’ commitment to innovation, quality, and customer satisfaction has solidified its position as a trusted name in the industry.

Retaining Ring 3068768 Compatibility with Cummins Engines

The Cummins Retaining Ring part number 3068768 is designed to fit a variety of Cummins engines, ensuring secure and reliable performance across multiple models. This retaining ring is crucial for maintaining the integrity of engine components by preventing unwanted movement and wear.

ISM Series Engines

- ISM CM570

- ISM CM570/870

- ISM CM876

- ISM11 CM876 SN

The ISM series engines, including the ISM CM570, ISM CM570/870, ISM CM876, and ISM11 CM876 SN, all utilize the 3068768 retaining ring to secure various components within the engine. This part is integral to the smooth operation and longevity of these engines.

ISX Series Engines

- ISX CM570

- ISX CM870

- ISX CM871

The ISX series engines, such as the ISX CM570, ISX CM870, and ISX CM871, also benefit from the use of the 3068768 retaining ring. This component is essential for maintaining the alignment and stability of critical engine parts, ensuring optimal performance and durability.

CELECT Series Engines

- L10 CELECT

- M11 CELECT

- M11 CELECT PLUS

- N14 CELECT PLUS

The CELECT series engines, including the L10 CELECT, M11 CELECT, M11 CELECT PLUS, and N14 CELECT PLUS, incorporate the 3068768 retaining ring to secure components and prevent misalignment. This part is vital for the reliable operation of these engines.

QSM and QSNT Series Engines

- QSM11 CM570

- QSM11 CM876

- QSN14 CM876 N102

- QSNT14 CM876 N102

The QSM and QSNT series engines, such as the QSM11 CM570, QSM11 CM876, QSN14 CM876 N102, and QSNT14 CM876 N102, also utilize the 3068768 retaining ring. This part ensures that the engine components remain securely in place, contributing to the overall efficiency and lifespan of these engines.

Role of Part 3068768 Retaining Ring in Engine Systems

The Part 3068768 Retaining Ring is an essential component in various engine systems, ensuring the secure assembly and operation of multiple parts. Its application spans across several key components, contributing to the overall performance and reliability of the engine.

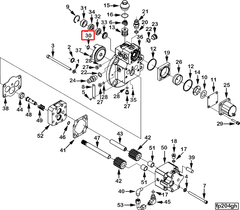

Fuel System Integration

In the fuel system, the Retaining Ring is utilized in the Fuel Pump and Fuel Base Pump assemblies. It secures the Injector Nozzle within the Injector, ensuring a tight seal and preventing fuel leakage. This is particularly important in high-pressure fuel systems where even minor leaks can significantly affect performance and efficiency.

Piston and Valve Mechanisms

The Retaining Ring plays a significant role in the Engine Piston assembly. It is used to secure the piston pin within the connecting rod, ensuring smooth and consistent piston movement. This is vital for maintaining engine balance and reducing wear on piston components.

Check Valve Functionality

In the Check Valve system, the Retaining Ring ensures that the valve components are held in place under varying pressure conditions. This is essential for maintaining the integrity of the fuel flow and preventing backflow, which could lead to engine inefficiencies.

Mounting and Performance

The Retaining Ring is also integral in the Mounting of various engine components. It ensures that parts such as the Fuel Pump and Injector are securely fastened to their respective mounts, reducing vibrations and enhancing the overall performance of the engine.

Comprehensive Application

Across all these applications, the Retaining Ring contributes to the secure assembly of parts, enhancing the durability and performance of the engine. Its role in preventing component displacement and ensuring tight seals is fundamental to the efficient operation of modern engine systems.

Conclusion

The Cummins 3068768 Retaining Ring is a critical component in the operation and maintenance of commercial trucks and various Cummins engines. Its design and features ensure the secure assembly and reliable performance of engine components, contributing to the overall efficiency and longevity of the systems it supports. Regular maintenance and prompt troubleshooting of any issues are essential to maximize the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.