3064523

Retaining Ring

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

Minimum Quantity 2

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3064523 Retaining Ring is a specialized component designed for use in heavy-duty truck engines. Its purpose is to secure various engine components in place, ensuring they function correctly under the demanding conditions typical of heavy-duty applications. The significance of this retaining ring lies in its ability to maintain the integrity and performance of critical engine parts, contributing to the overall reliability and efficiency of the truck 1.

Basic Concepts of Retaining Rings

Retaining rings, also known as circlips, are mechanical fasteners used to prevent components from moving along a shaft or within a housing. They operate by fitting into a groove and exerting a radial force that holds the component in position. Retaining rings are widely used in various mechanical systems due to their simplicity, effectiveness, and ease of installation and removal 2.

Purpose of the Cummins 3064523 Retaining Ring

The Cummins 3064523 Retaining Ring plays a specific role in securing components within the engine, such as bearings, gears, and other rotating parts. By keeping these components in their designated positions, the retaining ring helps maintain the precise alignment and operation of the engine systems. This is particularly important in heavy-duty trucks, where the engine is subjected to high loads and stresses 3.

Key Features

The Cummins 3064523 Retaining Ring is designed with several features that enhance its functionality and durability. It is typically made from high-strength materials such as spring steel, which provides the necessary resilience and resistance to wear. The ring’s design includes a coiled shape that allows it to expand and contract, fitting securely into grooves without the need for additional fasteners. This design also facilitates easy installation and removal using simple tools.

Benefits of Using the Cummins 3064523 Retaining Ring

Using the Cummins 3064523 Retaining Ring offers several advantages. It improves the reliability of the engine by ensuring that components remain in place under operational stress. The ease of installation reduces downtime during maintenance, and its durable construction minimizes the need for frequent replacements. Additionally, the retaining ring contributes to maintenance efficiency by simplifying the process of securing and releasing components.

Installation Process

Installing the Cummins 3064523 Retaining Ring involves a few straightforward steps. First, ensure the groove where the ring will be placed is clean and free of debris. Using a retaining ring plier, expand the ring and position it over the component. Carefully place the ring into the groove, ensuring it sits flush and secure. The plier can then be used to compress the ring slightly, ensuring a tight fit. Always follow the manufacturer’s guidelines for the specific application to ensure proper installation.

Common Issues and Troubleshooting

Typical problems with retaining rings may include improper seating, damage from wear, or incorrect sizing. If a retaining ring fails to secure a component properly, it may be due to an incorrectly sized ring or damage to the groove. Troubleshooting involves inspecting the ring and groove for any signs of wear or misalignment. Replacing a damaged ring or repairing the groove may be necessary to resolve the issue.

Maintenance Tips

Regular inspection of the Cummins 3064523 Retaining Ring is recommended to ensure optimal performance and longevity. Check for signs of wear, corrosion, or damage during routine maintenance checks. Ensure that the groove remains clean and free of debris, as accumulation can affect the ring’s ability to secure components effectively. Following these maintenance practices helps prevent unexpected failures and extends the service life of the retaining ring.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the automotive and heavy-duty truck industry. The company’s extensive product range includes engines, powertrains, and related components, all designed to meet the demanding requirements of various applications 4.

Applications of the Cummins 3064523 Retaining Ring

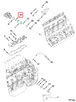

The retaining ring part number 3064523, manufactured by Cummins, is a critical component in several of their engine models. This part is designed to secure various parts within the engine, ensuring they remain in place during operation.

In the G8.3 engines, the retaining ring is used to hold certain internal components, maintaining the structural integrity and operational efficiency of the engine. Similarly, in the ISX12 G CM2180 EJ engines, this part plays a vital role in securing components that are essential for the engine’s performance.

For the QSK19 CM500 engines, the retaining ring part 3064523 is integral to the engine’s design, providing stability and support to critical parts. The same applies to the QSK19G engines, where this part ensures that the internal components are properly aligned and secured.

Across these engines, the retaining ring is a common component, highlighting its importance in the overall design and functionality of Cummins engines.

Role of Part 3064523 Retaining Ring in Engine Systems

The Part 3064523 Retaining Ring is an essential component in various engine systems, ensuring the secure placement and operation of multiple parts.

In the Accessory Drive system, the retaining ring helps maintain the alignment and positioning of gears and pulleys, which are vital for the operation of ancillary components like the alternator and water pump.

Within the Ignition System, it plays a part in securing the ignition components, ensuring that the spark plugs and related parts remain in their correct positions for reliable ignition.

In the Cylinder Block, the retaining ring is used to hold various components in place, contributing to the structural integrity and operational efficiency of the engine.

For the Cam Follower Lever and Cam Follower Shaft, the retaining ring ensures these parts are correctly positioned relative to the camshaft, which is essential for the accurate timing of valve operations.

In the Cam Follower Top Level Assembly Lever and Cam Top Level Assembly Follower, the retaining ring secures these components, ensuring they interact correctly with the camshaft for optimal engine performance.

The Valve Cover utilizes the retaining ring to secure O-rings and gaskets, maintaining the seal integrity around the valve train components.

In the Fluid Top Level Assembly Coupling and various Service Coupling Assemblies (2008, 2009), the retaining ring ensures that fluid lines and couplings remain securely attached, preventing leaks and ensuring proper fluid flow.

For the Flywheel and Plumbing systems, the retaining ring helps in securing bolts and fittings, ensuring these systems function without unintended movement or disconnection.

Lastly, in the Short Block Kit and overall Engine System, the retaining ring is used in multiple locations to secure components, ensuring the engine’s reliability and performance.

Conclusion

The Cummins 3064523 Retaining Ring is a vital component in heavy-duty truck engines, ensuring the secure placement and operation of various engine parts. Its design, made from high-strength materials and featuring a coiled shape, allows for easy installation and removal while providing durability and reliability. Regular maintenance and proper installation are key to maximizing the performance and longevity of this part.

-

Harrison, Matthew. Controlling Noise and Vibration in Road Vehicles. SAE International, 2004.

↩ -

Peters, George, and Barbara J Peters. Automobile Vehicle Safety. CRC Press, 2002.

↩ -

Gillespie, Thomas D. Fundamentals of Vehicle Dynamics. SAE International, 2021.

↩ -

Cummins Inc. Owners Manual for QSK60 CM2350 K136. Bulletin Number 5504629.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.