This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

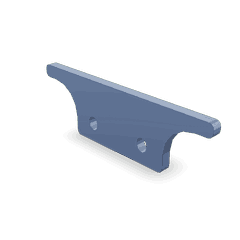

The Tube Retaining Clip 2866794, manufactured by Cummins, is a component designed for use in commercial truck operations. Cummins, a well-established name in the industry, produces a range of parts and systems aimed at enhancing the efficiency and reliability of heavy-duty trucks. This Cummins part is integral to the maintenance and operation of various truck systems.

Purpose and Function

The Tube Retaining Clip 2866794 serves a specific role in the operation of a truck. It is utilized to secure tubes within the truck’s systems, ensuring they remain in place under various operating conditions. This clip is particularly important in systems where tubes are subject to vibration or movement, such as in the engine compartment or along the frame of the truck. By securing the tubes, it helps maintain the integrity of fluid pathways, which is vital for the proper functioning of the truck’s systems 1.

Key Features

The design and material characteristics of the Tube Retaining Clip 2866794 contribute to its effectiveness and longevity. Constructed from durable materials, it is capable of withstanding the harsh conditions often encountered in commercial truck environments. Its design allows for easy installation, accommodating various tube sizes and types. This versatility ensures that it can be used in different applications across a range of truck models 2.

Benefits

The advantages provided by the Tube Retaining Clip 2866794 include enhanced security of tube connections, which reduces the risk of disconnections or leaks. This security leads to a reduction in maintenance requirements, as the tubes are less likely to become dislodged or damaged. Additionally, the clip contributes to the overall reliability of the truck’s systems by ensuring that tubes remain properly positioned and connected 3.

Installation Process

Proper installation of the Tube Retaining Clip 2866794 involves several steps to ensure a secure fit. First, the tube should be positioned in its intended location. The clip is then placed over the tube and secured in place, following the manufacturer’s guidelines for torque specifications if applicable. Tools required may include a wrench or pliers, depending on the specific design of the clip. It is important to follow best practices during installation to ensure that the clip is properly aligned and tightened to the correct specifications.

Troubleshooting Common Issues

Typical problems that may arise with the Tube Retaining Clip 2866794 include improper fit or damage to the clip. If the clip does not fit securely, it may be necessary to reassess the tube’s position or consider a different size clip. Damage to the clip, such as cracks or deformation, may require replacement. Regular inspection can help identify issues early, allowing for timely maintenance or replacement.

Maintenance Tips

Regular inspection and care of the Tube Retaining Clip 2866794 are recommended to prolong its lifespan and ensure continued efficient operation. This includes checking for signs of wear or damage, ensuring that the clip remains securely fastened, and verifying that the tubes are properly aligned. Cleaning the clip and surrounding area can also help prevent buildup that may affect its performance.

Cummins Overview

Cummins is a manufacturer with a significant presence in the commercial truck industry. With a history of innovation and quality, Cummins offers a wide range of products designed to enhance the performance and reliability of heavy-duty trucks. Their reputation is built on a commitment to excellence and a comprehensive product range that meets the diverse needs of the trucking industry.

Tube Retaining Clip (Part 2866794) in Cummins Engines

The Tube Retaining Clip, part number 2866794, manufactured by Cummins, is a critical component in several of their engine models. This part is designed to secure and stabilize various tubes within the engine, ensuring that they remain in place and function correctly.

Application in Cummins Engines

QSK60 Series

In the QSK60 series, the Tube Retaining Clip is used to maintain the integrity of the coolant and oil passages. These engines are known for their robust design and high performance, often used in heavy-duty applications such as marine and stationary power generation. The clip ensures that the tubes do not shift or become dislodged, which could lead to leaks or system failures.

CM850 Series

The CM850 series engines benefit from the Tube Retaining Clip in maintaining the structural integrity of the fuel and coolant systems. These engines are typically found in on-highway and vocational applications, where reliability and efficiency are paramount. The clip’s role in securing the tubes helps in preventing any misalignment that could affect the engine’s performance.

MCRS Series

In the MCRS series, the Tube Retaining Clip is essential for securing the tubes in the engine’s lubrication system. These engines are designed for medium-duty applications, providing a balance between power and fuel efficiency. The clip ensures that the tubes remain properly aligned, which is crucial for the smooth operation of the engine’s lubrication system.

Importance of the Tube Retaining Clip

The Tube Retaining Clip is a small but vital component that ensures the longevity and reliability of the engine. By securing the tubes, it prevents potential leaks and system failures, contributing to the overall performance and durability of the engine. Its application across various Cummins engine series highlights its importance in maintaining the integrity of the engine’s internal systems.

Role of Part 2866794 Tube Retaining Clip in Engine Systems

The part 2866794 Tube Retaining Clip is instrumental in ensuring the secure attachment and stability of tubes within various engine systems. In the system component, this clip plays a significant role by maintaining the proper alignment and connection of tubes that carry essential fluids such as coolant, oil, or fuel. This ensures efficient fluid transfer and reduces the risk of leaks, which could lead to system failure or decreased performance.

In the auxiliary cooling component, the Tube Retaining Clip is equally important. It secures the tubes that are part of the auxiliary cooling system, which is designed to provide additional cooling to critical engine components. This system often includes radiators, heat exchangers, and cooling fans. The clip ensures that the tubes remain firmly in place, even under the stress of engine vibrations and temperature fluctuations. This stability is vital for maintaining the integrity of the cooling system, ensuring that it operates effectively to prevent engine overheating.

Overall, the Tube Retaining Clip contributes to the reliability and efficiency of these engine systems by providing a simple yet effective solution for tube retention.

Conclusion

The Tube Retaining Clip 2866794 is a crucial component in the maintenance and operation of commercial truck systems. Its role in securing tubes ensures the integrity of fluid pathways, contributing to the overall reliability and efficiency of the truck’s systems. Proper installation, regular maintenance, and timely troubleshooting are essential to maximize the benefits of this part. Cummins’ commitment to quality and innovation is evident in the design and functionality of the Tube Retaining Clip, making it a valuable asset in the operation of heavy-duty trucks.

-

Dixon, John. Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning, 2014.

↩ -

Wright, Gus. Fundamentals of Medium-Heavy Duty Diesel Engines. Jones & Bartlett Learning, 2015.

↩ -

Hillier, Alma. Fundamentals of Motor Vehicle Technology Book 1 6th Edition. Oxford University Press, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.