This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4371927 Push Rod is a component designed for use in heavy-duty truck engines. It plays a role in the engine’s operation by facilitating the transfer of motion from the camshaft to the valves, ensuring precise timing and efficient engine performance.

Basic Concepts of Push Rods

Push rods are mechanical links used in overhead valve (OHV) engines to transmit motion from the camshaft to the valves. Positioned between the camshaft and the rocker arms, push rods convert the rotational motion of the camshaft into linear motion, which opens and closes the engine valves at the correct times 1.

Purpose and Role of the 4371927 Push Rod

The Cummins 4371927 Push Rod is integral to the valve train mechanism of a truck engine. It interacts with the camshaft and rocker arms to ensure that the valves open and close in sync with the engine’s operation. This precise timing is important for the engine’s efficiency and performance.

Key Features

This Cummins part is constructed from high-quality materials, ensuring durability and reliability under the demanding conditions of heavy-duty truck engines. Its design includes specific dimensions and tolerances to fit seamlessly within the engine’s valve train system, contributing to smooth operation and longevity.

Benefits

Utilizing the 4371927 Push Rod in an engine setup can lead to improved efficiency, reliability, and longevity. Its robust construction and precise engineering help maintain optimal valve timing, which is vital for the engine’s overall performance and fuel efficiency 2.

Installation and Compatibility

Proper installation of this part involves careful alignment with the camshaft and rocker arms to ensure smooth operation. It is designed to be compatible with specific Cummins engine models, ensuring a precise fit and function within the engine’s valve train system.

Maintenance and Troubleshooting

Routine maintenance of the 4371927 Push Rod includes regular inspections for wear and damage. Common issues with push rods can include bending or excessive wear, which may affect engine performance. Troubleshooting typically involves checking for proper alignment and condition, and replacing the push rod if necessary.

Performance Enhancements

Upgrading or modifying the push rod system, including the use of the 4371927 Push Rod, can have a noticeable impact on engine performance and efficiency. Enhancements may include the use of higher-quality materials or adjustments to the push rod’s length and diameter to optimize valve timing and engine output.

Cummins Overview

Cummins Inc. is renowned for its high-quality automotive components, with a strong reputation for innovation and excellence in the industry. The company’s commitment to producing reliable and efficient parts is evident in its wide range of products, including the 4371927 Push Rod, which is designed to meet the rigorous demands of heavy-duty truck engines.

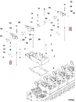

Cummins Push Rod 4371927 in QSK19 Engines

The Cummins Push Rod 4371927 is a component in the QSK19 series of engines, including both the QSK19 CM500 and the QSK19G variants. This push rod is integral to the engine’s valvetrain system, ensuring the smooth and reliable operation of the engine’s valves.

In the QSK19 CM500 engine, the push rod 4371927 is designed to withstand the high-stress environment of the engine, providing a durable connection between the camshaft and the valve. The precision engineering of this part ensures that it can handle the rigorous demands of the engine’s operation, contributing to the overall efficiency and longevity of the engine.

Similarly, in the QSK19G engine, the push rod 4371927 plays a role in the valvetrain mechanism. Its design and material composition are tailored to meet the specific requirements of the QSK19G engine, ensuring that it can perform reliably under various operating conditions. The push rod’s ability to maintain consistent contact with the camshaft and valve is important for the engine’s performance and durability.

Both engines benefit from the use of the Cummins Push Rod 4371927, which is manufactured to stringent quality standards. This ensures that the part will function effectively within the engine’s complex system, contributing to the overall reliability and efficiency of the QSK19 series engines.

Role of Part 4371927 Push Rod in Engine Systems

In the orchestration of an engine’s valve train, the part 4371927 Push Rod serves as an intermediary. This component is instrumental in transmitting motion from the camshaft to the valve mechanism, ensuring precise and timely valve operation.

When the camshaft rotates, it actuates the lifter, which in turn moves the Push Rod. The Push Rod then extends or retracts, depending on the camshaft’s profile, to actuate the rocker arm. The rocker arm, a lever, amplifies the motion imparted by the Push Rod, transferring it to the valve. This mechanism allows for the opening and closing of the valve with the necessary force and speed, facilitating the intake and exhaust processes within the combustion chamber.

The Push Rod’s role is significant in maintaining the integrity of the valve timing. Its consistent and reliable operation ensures that the valves open and close in harmony with the piston’s movement, which is important for engine performance and efficiency. The Push Rod’s design allows for the absorption of some of the shock and vibration generated during engine operation, contributing to the longevity of the valve train components 3.

Conclusion

In summary, the part 4371927 Push Rod is a key component in the valve train, working in concert with the camshaft, lifter, rocker arm, and valve to facilitate the engine’s operation. Its function is to transmit motion efficiently and reliably, ensuring that the engine’s valves operate in precise accordance with the engine’s requirements.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.