4095511

Push Rod

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4095511 Push Rod is a critical component in heavy-duty truck engines, facilitating the transfer of motion from the camshaft to the valves. This transfer is essential for the engine’s intake and exhaust functions, directly impacting performance and efficiency 1.

Basic Concepts of Push Rods

Push rods are mechanical components in overhead valve (OHV) engines, connecting the camshaft in the engine block to the rocker arms in the cylinder head. Their primary role is to transmit the camshaft’s rotational motion to the rocker arms, which actuate the valves. This mechanism ensures precise control over valve timing and duration, crucial for engine operation 2.

Purpose of the Cummins 4095511 Push Rod

The Cummins 4095511 Push Rod is engineered to enhance valve operation efficiency and reliability in Cummins engines. It ensures precise valve timing, optimizing engine performance, fuel efficiency, and emissions 3.

Key Features

Constructed from high-quality materials, the Cummins 4095511 Push Rod offers durability and wear resistance. Its design features a smooth surface finish to reduce friction and precise dimensions for accurate valve actuation, contributing to its reliability and longevity in demanding engine environments.

Benefits

Using the Cummins 4095511 Push Rod provides several advantages, including improved engine efficiency through precise valve timing and enhanced engine reliability and longevity due to its robust construction. It is designed to withstand the rigors of heavy-duty truck operation, ensuring consistent performance over time.

Installation and Compatibility

Proper installation of the Cummins 4095511 Push Rod is essential for optimal engine performance. It should be installed according to the manufacturer’s guidelines to avoid issues such as misalignment or excessive wear. Compatibility with specific engine models and configurations should be verified to ensure correct function within the engine system.

Troubleshooting and Maintenance

Common issues with push rods include wear and bending, which can lead to valve train noise, decreased engine performance, or engine failure. Regular maintenance, including inspection for wear signs and proper lubrication, can help prevent these issues. Promptly addressing push rod problems is important for maintaining engine health and performance.

Performance Enhancements

The Cummins 4095511 Push Rod contributes to engine performance enhancements by ensuring precise valve actuation, leading to increased horsepower, torque, and fuel efficiency. Its design and material composition are optimized to handle the demands of heavy-duty truck engines, supporting overall engine performance improvements.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the heavy-duty truck industry. The company’s commitment to engineering excellence is evident in its wide range of engine components, including the Cummins 4095511 Push Rod, designed to meet high performance and reliability standards in heavy-duty applications.

Cummins Push Rod 4095511 Compatibility

The Cummins Push Rod part number 4095511 is designed for specific Cummins engines, ensuring proper valve operation and overall engine performance. It is integral to the engine’s valve train system.

QSK23 Engines

The Cummins QSK23 engines, including the QSK23 CM2250 and QSK23 CM500, utilize the 4095511 push rod. This part is crucial for maintaining precise valve timing and movement. The QSK23 series is known for its robust design and high performance, making the correct installation of components like the push rod essential for optimal engine function.

Installation and Function

In the QSK23 CM2250 and QSK23 CM500 engines, the 4095511 push rod interfaces with the camshaft and valve train, ensuring that the valves open and close at the correct intervals. This synchronization is vital for the engine’s efficiency and longevity. The push rod’s design allows it to withstand the high pressures and temperatures within the engine, providing a reliable connection between the camshaft and the valve.

Importance of Proper Installation

Proper installation of the 4095511 push rod is critical. Any misalignment or improper fit can lead to valve timing issues, resulting in reduced performance, increased wear, and potential engine damage. Technicians should follow the manufacturer’s guidelines for installation, ensuring that the push rod is correctly aligned and securely fastened.

Maintenance Considerations

Regular maintenance of the push rod and its associated components is essential to prevent premature wear and failure. This includes periodic inspection for signs of wear, proper lubrication, and timely replacement if any damage is detected. Ensuring that the push rod remains in good condition is a key aspect of maintaining the overall health of the QSK23 engines.

Role of Part 4095511 Push Rod in Engine Systems

The 4095511 Push Rod is integral to the operation of various engine systems, facilitating the transfer of motion from the camshaft to the valve train. This transfer is essential for the precise timing of valve opening and closing, directly influencing engine performance and efficiency.

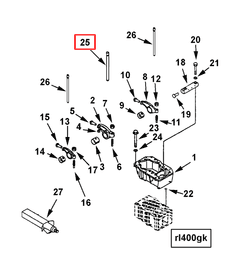

Interaction with the Block and Cylinder

Within the engine block, the push rod connects the camshaft, located in the cylinder head, to the valve train components. As the camshaft rotates, driven by the crankshaft, it actuates the cam followers. This action generates a lifting force that is transmitted through the push rod.

Cam Follower and Lever Mechanism

The cam follower, typically a lifter or tappet, makes direct contact with the camshaft lobes. When a lobe rises, it pushes the cam follower upward. This upward motion is then conveyed to the push rod, which extends or compresses in response. The push rod, in turn, interacts with the lever mechanism—commonly a rocker arm—to amplify this motion.

Rocker Arm Functionality

The rocker arm, a type of lever, is pivotal in the valve train system. The push rod pushes against one end of the rocker arm, causing it to pivot. This pivoting action lifts the valve off its seat within the cylinder head, allowing air and fuel to enter the combustion chamber or exhaust gases to exit.

Summary of Component Interaction

In summary, the 4095511 Push Rod serves as a vital link in the engine’s valve train system. It ensures that the motion initiated by the camshaft is effectively transmitted to the rocker arm, which then actuates the valves. This seamless transfer of motion is fundamental to the engine’s operation, enabling it to perform efficiently and reliably.

Conclusion

The Cummins 4095511 Push Rod plays a significant role in the operation of heavy-duty truck engines by ensuring precise valve timing and actuation. Its high-quality construction, compatibility with specific engine models, and the importance of proper installation and maintenance contribute to enhanced engine performance, reliability, and longevity. Understanding the role and proper care of this Cummins part is essential for maintaining the efficiency and effectiveness of Cummins engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.