This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4080240 Push Rod Assembly is a component designed for use in heavy-duty truck engines. It plays a role in the engine’s operation by facilitating the movement of the valve train. Understanding its purpose and significance is key to maintaining the efficiency and reliability of heavy-duty trucks.

Basic Concepts of Push Rod Assemblies

A push rod assembly is a mechanical linkage used in overhead valve (OHV) engines. It connects the camshaft to the valves, allowing the camshaft to control the opening and closing of the valves. This assembly typically consists of a rod that transfers motion from the camshaft’s lobes to the rocker arms, which then actuate the valves. The push rod plays a role in the engine’s valve train mechanism by ensuring precise timing and operation of the valves 1.

Purpose of the 4080240 Push Rod Assembly

This Cummins part is specifically engineered to operate within the valve train of a truck engine. It interacts with the camshaft and rocker arms to facilitate the opening and closing of the engine’s valves. This assembly ensures that the valves operate in sync with the engine’s timing, contributing to the engine’s overall performance and efficiency.

Key Features

The 4080240 is constructed from high-quality materials, ensuring durability and reliability under the demanding conditions of heavy-duty truck operation. Its design includes precise dimensions and tolerances to ensure smooth operation and compatibility with other engine components. Unique characteristics such as its robust construction and precise engineering enhance its performance and longevity 2.

Benefits

The use of the 4080240 in a truck engine can lead to improved engine efficiency, as it ensures that the valve train operates smoothly and reliably. Its durable construction contributes to the engine’s longevity, while its precise engineering enhances the engine’s reliability. These factors combined make this Cummins part a valuable component in the operation of heavy-duty trucks.

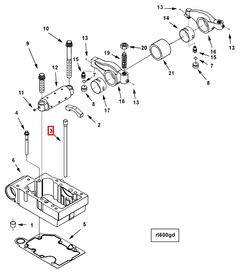

Installation Process

Installing the 4080240 requires careful attention to detail and the use of appropriate tools. The process involves aligning the push rod with the camshaft and rocker arm, ensuring that it is properly seated and secured. It is important to follow manufacturer guidelines to ensure correct installation and to avoid potential issues.

Troubleshooting Common Issues

Common problems associated with push rod assemblies include wear and tear, which can lead to decreased performance or engine issues. Regular inspection and maintenance can help identify and address these problems. Troubleshooting methods may include checking for proper alignment, inspecting for signs of wear, and ensuring that all connections are secure 3.

Maintenance Tips

Regular maintenance practices are key to ensuring the longevity and optimal performance of the 4080240. This includes regular inspections for signs of wear or damage, ensuring that all connections are secure, and following manufacturer guidelines for maintenance and replacement. Proper care and maintenance can help prevent issues and ensure the assembly continues to operate efficiently.

Cummins Overview

Cummins Inc. is a well-established company in the automotive industry, known for its production of high-quality heavy-duty truck components. With a history of innovation and a reputation for reliability, Cummins has become a trusted name in the industry. The company’s commitment to quality and performance is evident in its range of products, including the 4080240.

Push Rod Assembly 4080240 Compatibility with Cummins Engines

The Push Rod Assembly 4080240, manufactured by Cummins, is a critical component in several of their engine models. This part is integral to the engine’s operation, ensuring the proper functioning of the valve train system. Below is a detailed look at the compatibility of this part with various Cummins engines.

QSK45 CM500 and QSK60 CM500

The Push Rod Assembly 4080240 is compatible with both the QSK45 CM500 and QSK60 CM500 engines. These engines are part of Cummins’ QSK series, known for their robust design and reliability in demanding applications. The push rod assembly ensures that the valves open and close in synchronization with the engine’s camshaft, maintaining optimal performance and efficiency.

QSK60 CM850 MCRS and QSK60 G CM2358 K110

The Push Rod Assembly 4080240 also fits the QSK60 CM850 MCRS and QSK60 G CM2358 K110 engines. These engines are part of the QSK60 series, which is designed for heavy-duty applications, including marine and industrial use. The push rod assembly in these engines plays a crucial role in maintaining the precise timing required for the valves to operate correctly, ensuring the engine runs smoothly and efficiently.

QSK60G

Lastly, the Push Rod Assembly 4080240 is also compatible with the QSK60G engine. This engine is another variant in the QSK60 series, offering a balance of power and reliability. The push rod assembly in this engine is essential for the proper functioning of the valve train, contributing to the overall performance and longevity of the engine.

In summary, the Push Rod Assembly 4080240 is a versatile component that fits seamlessly into various Cummins engines, ensuring the smooth operation of the valve train system. Its compatibility with the QSK45 CM500, QSK60 CM500, QSK60 CM850 MCRS, QSK60 G CM2358 K110, and QSK60G engines underscores its importance in maintaining engine performance and reliability.

Role of Part 4080240 Push Rod Assembly in Engine Systems

The 4080240 is an essential component in the operation of overhead valve (OHV) engine systems. It serves as the mechanical link between the camshaft and the valve train, ensuring precise and efficient valve actuation.

Interaction with the Rocker Arm

In an OHV engine, the push rod assembly directly interfaces with the rocker arm. When the camshaft lobe rotates, it pushes against the base of the push rod. This linear motion is transmitted through the push rod to the rocker arm. The rocker arm, in turn, amplifies this motion to open and close the engine’s valves at the correct timing. This setup allows for efficient valve operation, ensuring optimal engine performance and fuel efficiency.

Coordination with the Lever Mechanism

In some engine designs, a lever mechanism may be incorporated into the valve train system. The push rod assembly works in conjunction with this lever to further modulate the valve’s opening and closing cycles. The lever can adjust the force applied to the valve, allowing for fine-tuning of the engine’s performance characteristics. This interaction ensures that the valves open to the precise degree required for the engine’s current operating conditions, whether idling or under full load.

Ensuring Smooth Operation

The push rod assembly must maintain a smooth and consistent connection between the camshaft and the rocker arm or lever mechanism. Any irregularities in this connection can lead to valve train noise, reduced engine efficiency, and potential damage to other components. Therefore, the design and material of the push rod assembly are optimized to withstand the high stresses and temperatures within the engine compartment while providing reliable performance over the engine’s lifespan.

Conclusion

The Cummins 4080240 Push Rod Assembly is a critical component in the operation of heavy-duty truck engines. Its role in the valve train system ensures precise and efficient valve actuation, contributing to the engine’s overall performance and reliability. Understanding its features, benefits, and proper maintenance is essential for ensuring the longevity and efficiency of heavy-duty trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.