This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

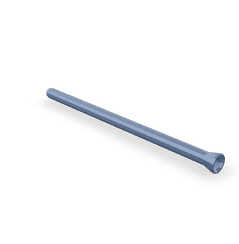

The Cummins 3092507 Push Rod is a component designed for use in heavy-duty truck engines. It plays a role in the engine’s valve train by facilitating the transfer of motion from the camshaft to the valves, ensuring that the valves open and close at the precise moments required for optimal engine performance 1.

Basic Concepts of Push Rods

Push rods are mechanical components found in overhead valve (OHV) engines. They connect the camshaft, which is typically located in the engine block, to the valves situated in the cylinder head. Push rods transmit the rotational motion of the camshaft into linear motion, which operates the valves. This mechanism is important for controlling the intake and exhaust of air and fuel in the combustion process 2.

Purpose of the Cummins 3092507 Push Rod

This Cummins part is specifically engineered to enhance the efficiency and reliability of the valve train in Cummins engines. It transmits motion from the camshaft to the rocker arms, which then actuate the valves. This precise transmission of motion ensures that the valves open and close in sync with the engine’s operational requirements, contributing to smooth and efficient engine performance.

Key Features

The Cummins 3092507 Push Rod is constructed from high-quality materials, ensuring durability and reliability under the demanding conditions of heavy-duty truck operation. Its design includes features such as a robust construction and precise machining tolerances, which enhance its performance and longevity. Additionally, the push rod may incorporate specific attributes tailored to meet the rigorous standards of Cummins engines.

Benefits

The use of the Cummins 3092507 Push Rod offers several advantages. It contributes to improved engine efficiency by ensuring precise valve timing. The robust construction and high-quality materials used in its manufacture enhance the reliability and longevity of the engine’s valve train. Furthermore, the push rod’s design and material composition support overall engine performance, making it a valuable component in heavy-duty applications.

Installation and Compatibility

Proper installation of the Cummins 3092507 Push Rod is vital for ensuring the engine’s valve train operates correctly. Installation procedures should follow manufacturer guidelines to maintain the integrity of the engine’s performance. The push rod is compatible with specific Cummins engine models, designed to meet the operational requirements of these engines.

Maintenance and Troubleshooting

Regular maintenance of the Cummins 3092507 Push Rod is important for ensuring optimal engine performance. This includes periodic inspection for signs of wear or damage, ensuring proper lubrication, and adhering to recommended replacement intervals. Troubleshooting common issues related to push rod failure or malfunction may involve checking for proper installation, assessing for damage, and ensuring compatibility with the engine model.

Cummins Overview

Cummins Inc. is a renowned manufacturer in the automotive industry, known for its high-quality engine components. With a rich history and a strong reputation for reliability and performance, Cummins continues to be a leader in the production of engine parts for heavy-duty applications. The company’s commitment to quality and innovation is evident in its wide range of products, including the Cummins 3092507 Push Rod 3.

Role of Part 3092507 Push Rod in Engine Systems

The part 3092507 Push Rod is an integral component in the operation of several engine systems, particularly in overhead valve (OHV) and overhead cam (OHC) engines. Its primary function is to transmit motion from the camshaft to the valve train, ensuring precise and efficient valve operation.

Interaction with the Lever and Rocker

-

Lever Mechanism: In many engine designs, the push rod interfaces directly with a lever mechanism. This lever, often part of the rocker arm assembly, amplifies the motion transmitted by the push rod. The lever’s fulcrum allows it to convert the linear motion of the push rod into a rotational force, which is essential for opening and closing the valves with the required precision.

-

Rocker Arm Assembly: The push rod works in conjunction with the rocker arm to control valve timing. When the camshaft lobe pushes against the push rod, the rod extends and contacts the rocker arm. The rocker arm then pivots on its fulcrum, transferring the motion to the valve stem. This system ensures that the valves open and close at the correct intervals, maintaining engine efficiency and performance.

Detailed Functionality

-

Motion Transmission: The push rod’s role is to transmit the camshaft’s motion to the valve train components. This transmission is vital for the synchronized operation of the engine’s intake and exhaust valves.

-

Amplification of Force: By interacting with the lever and rocker arm, the push rod helps amplify the force applied by the camshaft. This amplification is necessary to overcome the spring pressure that keeps the valves closed, ensuring they open fully and promptly.

-

Precise Timing: The push rod ensures that the valves open and close at the precise moments required for optimal engine performance. Any deviation in this timing can lead to decreased efficiency, increased emissions, and potential engine damage.

Conclusion

In summary, the Cummins 3092507 Push Rod is a key element in the valve train system, working seamlessly with the lever and rocker arm to maintain the engine’s operational integrity and performance. Its robust construction, precise engineering, and compatibility with specific Cummins engine models make it a critical component for ensuring efficient and reliable engine operation.

-

Gilles, T. (2020). Automotive Service: Inspection, Maintenance, Repair: 2nd Edition. Cengage Learning.

↩ -

Viskup, R. (2020). Diesel and Gasoline Engines. IntechOpen.

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins Official Website.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.