This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

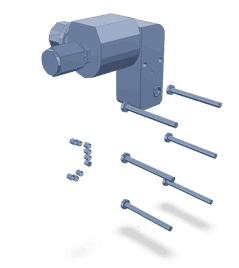

The Cummins 5273338 Doser Pump is a component designed for use in commercial trucks, specifically within the engine’s emissions control system. Its role is to inject Diesel Exhaust Fluid (DEF) into the exhaust stream, which is a key process in reducing nitrogen oxides (NOx) emissions. This part is significant for maintaining compliance with environmental regulations and ensuring the efficient operation of the truck’s engine.

Basic Concepts of Doser Pumps

A doser pump is a device that meters and injects DEF into the exhaust stream of a diesel engine. This injection occurs upstream of the Selective Catalytic Reduction (SCR) catalyst, where the DEF reacts with NOx to convert it into harmless nitrogen and water vapor. The doser pump’s function is integral to the SCR system’s effectiveness in controlling emissions 1.

Purpose of the Cummins 5273338 Doser Pump

The Cummins 5273338 Doser Pump is specifically engineered to work within the SCR system of a truck’s engine. It delivers precise amounts of DEF to the exhaust stream, facilitating the chemical reaction that reduces NOx emissions. This pump ensures that the SCR system operates efficiently, contributing to lower emissions and better environmental compliance.

Key Features

The Cummins 5273338 Doser Pump is characterized by its robust design and construction, which includes high-quality materials resistant to the corrosive nature of DEF. Technological advancements such as improved pump mechanisms and control systems enhance its performance and reliability, ensuring consistent DEF delivery under varying operating conditions 2.

Benefits of Using the Cummins 5273338 Doser Pump

Incorporating the Cummins 5273338 Doser Pump into a truck’s engine system offers several advantages. It contributes to improved emissions control, ensuring the vehicle meets stringent environmental standards. Additionally, the pump’s efficient operation can enhance engine performance and may lead to potential cost savings over time by reducing the need for frequent maintenance and repairs.

Troubleshooting and Maintenance Suggestions

Common issues with the Cummins 5273338 Doser Pump may include clogging or malfunctions due to DEF quality or pump wear. Regular maintenance practices, such as checking DEF quality, inspecting pump components for wear, and ensuring the system is free from contaminants, are recommended to maintain optimal performance. Troubleshooting steps may involve diagnosing electrical issues, checking for DEF leaks, and verifying pump operation.

Integration with Cummins Engines

The Cummins 5273338 Doser Pump is designed for seamless integration with Cummins engines. Its compatibility ensures that it works effectively with Cummins engine technology, enhancing the overall performance of the emissions control system. When used in conjunction with Cummins engines, the pump contributes to the engine’s efficiency and reliability.

Environmental Impact

The use of the Cummins 5273338 Doser Pump has a positive environmental impact by significantly reducing NOx emissions from diesel engines. This reduction contributes to cleaner air and compliance with environmental regulations, demonstrating Cummins’ commitment to sustainable engine technology.

Technological Advancements

The Cummins 5273338 Doser Pump incorporates several technological innovations, including advanced pump design, durable materials, and sophisticated control systems. These advancements enhance the pump’s efficiency, reliability, and performance, ensuring it meets the demands of modern diesel engine emissions control systems.

Cummins Company Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, related technologies, and complete power systems. With a history of innovation and a commitment to sustainability, Cummins plays a significant role in the development of advanced engine technologies and emissions control solutions 3.

Compatibility with Cummins Engines

The Doser Pump, identified by part number 5273338 and manufactured by Cummins, is an integral component in the fuel system of various Cummins engines. This part is designed to ensure precise dosing of fuel, which is critical for maintaining optimal engine performance and efficiency. Below is a detailed overview of the engines with which this doser pump is compatible:

Compatible Engines

- ISB/ISD4.5 CM2150 B119

- ISB/ISD6.7 CM2150 SN

- ISBE CM2150

- ISBE4 CM850

- ISL9 CM2150 SN

- ISL9.5 CM2880 L138

- ISM11 CM876 SN

- ISX15 CM2250 SN

- ISZ13 CM2150 Z105

Grouping of Compatible Engines

Group 1: ISB/ISD Series

- ISB/ISD4.5 CM2150 B119

- ISB/ISD6.7 CM2150 SN

These engines are part of the ISB/ISD series, which are known for their versatility and reliability in various applications, from commercial vehicles to industrial machinery.

Group 2: ISBE Series

- ISBE CM2150

- ISBE4 CM850

The ISBE series engines are designed for heavy-duty applications, providing robust performance and durability. The ISBE CM2150 and ISBE4 CM850 both benefit from the precise fuel dosing capabilities of the 5273338 doser pump.

Group 3: ISL Series

- ISL9 CM2150 SN

- ISL9.5 CM2880 L138

The ISL series engines are widely used in on-highway and vocational applications. The ISL9 CM2150 SN and ISL9.5 CM2880 L138 engines are equipped with the 5273338 doser pump to ensure efficient fuel management.

Group 4: ISM and ISX Series

- ISM11 CM876 SN

- ISX15 CM2250 SN

The ISM and ISX series engines are designed for heavy-duty on-highway applications. The ISM11 CM876 SN and ISX15 CM2250 SN engines utilize the 5273338 doser pump to maintain precise fuel dosing, which is essential for their high-performance characteristics.

Group 5: ISZ Series

- ISZ13 CM2150 Z105

The ISZ series engine is a specialized model used in specific applications. The ISZ13 CM2150 Z105 engine is compatible with the 5273338 doser pump, ensuring that it receives the precise fuel dosing it needs for optimal performance.

Role in Aftertreatment Systems

The Cummins 5273338 Doser Pump is an integral component within the aftertreatment system of modern diesel engines. Its primary function is to precisely inject Diesel Exhaust Fluid (DEF) into the exhaust stream. This process is essential for the Selective Catalytic Reduction (SCR) system to effectively reduce nitrogen oxides (NOx) emissions, ensuring compliance with environmental regulations.

Integration with Aftertreatment Devices

In the aftertreatment device, the Doser Pump works in conjunction with the SCR catalyst. The pump delivers a measured amount of DEF into the exhaust stream upstream of the catalyst. This injection facilitates a chemical reaction that converts NOx into harmless nitrogen and water vapor. The efficiency of this reaction is highly dependent on the accurate dosing provided by the pump.

Coordination with the Aftertreatment System

The aftertreatment system relies on the Doser Pump to maintain optimal DEF dosage. The system includes sensors that monitor exhaust gas composition and adjust the pump’s operation accordingly. This ensures that the SCR system operates within its designed parameters, maximizing its effectiveness in reducing emissions.

Interaction with the Diesel Exhaust Fluid Tank

The Doser Pump draws DEF from the diesel exhaust fluid tank. The pump’s performance is influenced by the quality and level of DEF in the tank. Regular maintenance and monitoring of the tank are necessary to ensure the pump operates efficiently and delivers the correct dosage.

Role in the Fluid Doser System

Within the fluid doser system, the Doser Pump is a key component. It is responsible for the precise and consistent injection of DEF. The pump’s operation is controlled by the engine’s Electronic Control Unit (ECU), which receives data from various sensors to determine the required DEF dosage. This integration ensures that the doser system responds dynamically to changing engine conditions.

Contribution to Overall Aftertreatment Performance

The effectiveness of the aftertreatment system is significantly influenced by the performance of the Doser Pump. Proper functioning of the pump ensures that the SCR system can effectively reduce NOx emissions, contributing to the overall efficiency and environmental compliance of the engine. Regular inspection and maintenance of the Doser Pump are essential to maintain the performance of the aftertreatment system.

Conclusion

The Cummins 5273338 Doser Pump plays a critical role in the emissions control system of diesel engines by ensuring the precise injection of DEF into the exhaust stream. Its integration with Cummins engines enhances the efficiency and reliability of the emissions control system, contributing to lower emissions and better environmental compliance. Regular maintenance and monitoring of the Doser Pump are essential to ensure its optimal performance and the overall effectiveness of the aftertreatment system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.