This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

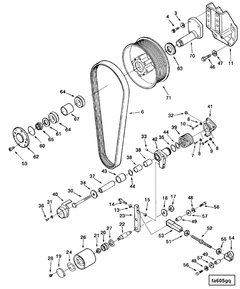

The 3639641 Idler Pulley, manufactured by Cummins, is a component designed for use in commercial trucks. Cummins, a well-established name in the engine manufacturing industry, produces this idler pulley to enhance the performance and reliability of truck engines. Idler pulleys play a significant role in automotive systems by maintaining the proper tension and alignment of belts within the engine’s accessory drive system 1.

Basic Concepts of Idler Pulleys

An idler pulley is a type of pulley that does not drive a component directly but instead supports and guides a belt or chain. Its function within a belt-driven system is to maintain tension and ensure proper alignment of the belt. Unlike drive pulleys, which are connected to a power source and transfer mechanical energy, idler pulleys do not transmit power but are crucial for the efficient operation of the belt system. The mechanical principles governing idler pulley operation include tension management and friction reduction, which are vital for the smooth and efficient transfer of power through the belt 2.

Purpose of the 3639641 Idler Pulley

The 3639641 Idler Pulley is specifically designed to play a role in the operation of a truck’s engine by maintaining belt tension and alignment within the accessory drive system. This ensures that the belt remains in optimal contact with other pulleys, which is necessary for the efficient operation of engine accessories such as the alternator, water pump, and air conditioning compressor 3.

Key Features

This Cummins part is characterized by its robust design and construction. It is made from high-quality materials that ensure durability and resistance to wear. The pulley features precision-engineered bearings that allow for smooth rotation and reduced friction. Additionally, unique design elements such as a corrosion-resistant coating and a balanced structure contribute to its performance and longevity.

Benefits of Using the 3639641 Idler Pulley

Incorporating this part into a truck’s engine system offers several advantages. It contributes to improved belt life by maintaining consistent tension and alignment. This reduces the likelihood of belt slippage and premature wear. Additionally, the pulley’s design helps in reducing noise and vibration within the engine compartment, leading to a smoother operation. Enhanced system efficiency is another benefit, as the proper functioning of the idler pulley ensures that engine accessories receive the necessary power transfer without loss.

Installation Considerations

When installing the 3639641 Idler Pulley, it is important to follow guidelines and best practices to ensure optimal performance. Proper alignment of the pulley with other components in the accessory drive system is crucial. Torque specifications provided by the manufacturer should be adhered to during installation to prevent over-tightening or under-tightening, which could lead to pulley failure or inefficient belt operation. Compatibility with other engine components must also be verified to ensure seamless integration into the engine system.

Troubleshooting Common Issues

Common problems associated with idler pulleys include noise, wear, and failure. Noise can often be attributed to improper belt tension or alignment, while wear may indicate the need for replacement. Failure of the pulley can result from bearing issues or material fatigue. Troubleshooting methods involve inspecting the pulley and belt for signs of wear, ensuring proper tension and alignment, and replacing worn or damaged components as necessary.

Maintenance Tips

Regular maintenance practices are key to ensuring the longevity and optimal performance of the 3639641 Idler Pulley. Inspection intervals should be established to check for signs of wear or damage. Lubrication requirements, if any, should be followed to maintain bearing health. Additionally, monitoring the pulley for any unusual noise or vibration can help in early detection of potential issues, allowing for timely intervention.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s commitment to excellence is evident in its engine components, including the 3639641 Idler Pulley, which are designed to meet the demanding requirements of commercial truck applications.

Idler Pulley 3639641 Compatibility with Cummins Engines

The Idler Pulley part number 3639641, manufactured by Cummins, is designed to fit into several of their engine models. This component plays a role in the engine’s operation by maintaining the proper tension of the engine’s belt system, ensuring smooth and efficient power transmission.

QSK38 Series

- QSK38 CM2150 MCRS

- QSK38 CM850 MCRS

The Idler Pulley 3639641 is compatible with the QSK38 series engines, specifically the CM2150 and CM850 models. These engines are part of the Cummins QSK38 lineup, known for their robust performance and reliability in various industrial applications.

QSK50 Series

- QSK50 CM2150 MCRS

- QSK50 CM2350 K108

For the QSK50 series, the Idler Pulley 3639641 is suitable for both the CM2150 and CM2350 models. The QSK50 engines are designed to deliver high power output and efficiency, making them ideal for heavy-duty applications. The K108 variant, in particular, is equipped with advanced features that enhance performance and durability.

The compatibility of the Idler Pulley 3639641 across these engine models ensures that it can be used as a reliable replacement part, maintaining the integrity of the belt system and contributing to the overall efficiency of the engine.

Role of Part 3639641 Idler Pulley in Engine Systems

The idler pulley, specifically part 3639641, is integral to maintaining the efficiency and reliability of various engine systems. It operates in conjunction with several components to ensure smooth and consistent performance.

Interaction with Belt Tensioner

The idler pulley works in tandem with the belt tensioner to maintain the appropriate tension on the drive belt. This ensures that the belt remains securely in place and operates efficiently, reducing the risk of slippage or premature wear. Proper tension is essential for the belt to transmit power effectively from the engine to other components.

Drive System Functionality

In the drive system, the idler pulley helps to guide the belt around the various pulleys and components it needs to engage. This guidance is vital for the consistent operation of the drive system, ensuring that power is distributed evenly and efficiently to components such as the alternator, water pump, and air conditioning compressor.

Fan Assembly Integration

The idler pulley also plays a role in the fan assembly by assisting in the proper alignment and tension of the belt that drives the fan. This ensures that the fan operates at the correct speed and efficiency, which is essential for maintaining optimal engine temperature and preventing overheating.

Idler Assembly Fan Coordination

Within the idler assembly, the idler pulley helps to manage the movement and tension of the belt as it interacts with the fan. This coordination is important for the overall performance of the cooling system, ensuring that the fan can respond quickly to changes in engine temperature and maintain a stable operating environment.

Overall, the idler pulley is a key component in ensuring the smooth and efficient operation of the engine’s auxiliary systems, contributing to the longevity and performance of the engine as a whole.

Conclusion

The 3639641 Idler Pulley is a critical component in the maintenance and operation of commercial truck engines. Its role in maintaining belt tension and alignment ensures the efficient operation of engine accessories and contributes to the overall reliability and performance of the engine. Proper installation, maintenance, and troubleshooting are essential to maximize the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.