This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3253187 Idler Pulley is a component designed for use in commercial trucks. It serves a specific function within the vehicle’s engine system, contributing to the efficient operation of various engine accessories. Understanding its role and significance can help in maintaining the overall performance and reliability of the truck.

Basic Concepts of Idler Pulleys

An idler pulley is a type of pulley used in belt drive systems to guide and maintain tension in the belt. It does not directly drive any component but ensures the belt remains properly aligned and tensioned, which is crucial for the efficient transfer of power between the driving and driven components. In mechanical systems, idler pulleys help in adjusting the path of the belt, accommodating changes in distance or alignment between the driving and driven components 1.

Purpose of the Cummins 3253187 Idler Pulley

This Cummins part is integral to the engine’s accessory drive system in commercial trucks. It plays a role in maintaining the correct tension and alignment of the belts that drive accessories such as the alternator, water pump, and air conditioning compressor. By ensuring these belts operate under the right conditions, the idler pulley contributes to the reliable and efficient functioning of these critical engine components 2.

Key Features

The 3253187 is constructed from durable materials, designed to withstand the rigors of commercial truck operation. Its design includes precision-machined surfaces and high-quality bearings, which enhance its performance and longevity. Additionally, the pulley may feature unique attributes such as a corrosion-resistant coating or a specific groove design to optimize belt grip and reduce slippage.

Benefits of Using the Cummins 3253187 Idler Pulley

Utilizing this part offers several advantages. It provides improved belt tension, which is vital for the efficient operation of engine accessories. Reduced wear on other components is another benefit, as proper belt tension minimizes stress on the system. Furthermore, the enhanced overall system efficiency contributes to better fuel economy and reduced maintenance costs.

Installation Considerations

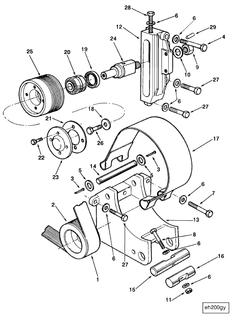

Proper installation of the 3253187 is crucial for its effective operation. This process may require specific tools and adherence to manufacturer guidelines to ensure correct alignment and tensioning of the belt. Attention to detail during installation helps prevent issues such as belt slippage or premature wear, ensuring the pulley functions as intended within the engine’s accessory drive system.

Troubleshooting Common Issues

Common problems associated with idler pulleys include noise, vibration, or belt slippage. These issues can often be traced back to improper installation, wear and tear, or misalignment. Diagnostic steps may involve inspecting the pulley and belt for signs of damage, ensuring correct alignment, and adjusting the tension as necessary. Addressing these issues promptly can help maintain the efficiency and reliability of the engine’s accessory drive system 3.

Maintenance Tips

Regular maintenance is key to ensuring the longevity and reliable operation of the 3253187. This includes periodic inspections for signs of wear or damage, such as cracks, corrosion, or excessive play in the pulley. Maintaining proper belt tension and alignment is also important. Following manufacturer-recommended inspection intervals and addressing any issues promptly can help prevent more significant problems down the line.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance components. Their product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicle applications.

Idler Pulley (Part 3253187) in Cummins Engines

The Idler Pulley, identified by part number 3253187, is a critical component in various Cummins engines. Its primary function is to maintain the proper tension of the engine’s serpentine belt, ensuring efficient power transfer and minimizing wear on the belt and associated components. This part is integral to the engine’s operation, as it helps in the smooth functioning of the alternator, water pump, and other accessories driven by the belt.

Application in Specific Cummins Engines

L10 MECHANICAL

In the L10 MECHANICAL engine, the Idler Pulley plays a vital role in maintaining the balance and alignment of the serpentine belt. This engine, known for its robust design and reliability, benefits from the precise tensioning provided by the 3253187 Idler Pulley. The correct tension ensures that the alternator and other belt-driven components operate efficiently, contributing to the overall performance and longevity of the engine.

The Idler Pulley’s design and placement in the L10 MECHANICAL engine are optimized to handle the specific demands of this engine model. Its robust construction and precise engineering make it a reliable choice for maintaining the integrity of the belt system, which is crucial for the engine’s smooth operation.

Importance of the Idler Pulley

The Idler Pulley is essential in preventing belt slippage and ensuring that the belt remains in contact with the pulleys it drives. This is particularly important in engines like the L10 MECHANICAL, where the belt must efficiently transfer power to multiple components. The 3253187 Idler Pulley, manufactured by Cummins, is designed to withstand the rigors of engine operation, providing consistent performance and reliability.

By maintaining the correct belt tension, the Idler Pulley helps in reducing the risk of belt failure and the associated downtime and repair costs. Its role in the engine’s accessory drive system is crucial, as it ensures that all belt-driven components receive the necessary power to function correctly.

Compatibility and Installation

The Idler Pulley part number 3253187 is specifically engineered to fit the L10 MECHANICAL engine and other compatible Cummins engines. Proper installation is essential to ensure that the Idler Pulley functions as intended. Technicians should follow the manufacturer’s guidelines for installation, including the correct alignment and tension settings, to maximize the lifespan and performance of the Idler Pulley.

Role of Part 3253187 Idler Pulley in Engine Systems

The idler pulley, specifically part 3253187, is an integral component in the operation of various engine systems. Its primary function is to maintain tension in the serpentine belt system, ensuring efficient power transmission to essential engine accessories.

Integration with Mounting Systems

When installed, the idler pulley is securely mounted to the engine block or a designated bracket. This mounting arrangement allows for precise alignment and tensioning of the serpentine belt. The pulley’s position is critical for the belt to run smoothly over other components, reducing wear and tear. Proper mounting of the idler pulley ensures that the belt remains in optimal condition, contributing to the longevity and performance of the engine system.

Interaction with the Alternator

The idler pulley works in conjunction with the alternator within the serpentine belt system. As the belt rotates around the idler pulley, it transfers mechanical energy to the alternator. This energy conversion is vital for the alternator to generate electrical power, which is then used to charge the battery and power the vehicle’s electrical systems. The consistent tension provided by the idler pulley ensures that the alternator receives a steady supply of mechanical energy, enabling it to operate efficiently and reliably.

Conclusion

In summary, the idler pulley part 3253187 plays a significant role in maintaining the integrity and performance of the serpentine belt system. Its proper installation and function are essential for the efficient operation of components such as the alternator, ultimately contributing to the overall reliability of the engine system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.