The Cummins 3100120 Idler Pulley is a component designed for use in commercial trucks. It serves a specific function within the truck’s belt-driven systems, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and operation is important for maintaining the truck’s performance and longevity.

Basic Concepts of Idler Pulleys

An idler pulley is a type of pulley that does not drive a machine part directly but instead supports and guides a belt or chain. It functions within a belt-driven system by maintaining proper belt tension and alignment. This ensures efficient power transmission and reduces wear on both the belt and the components it drives 1.

Purpose of the 3100120 Idler Pulley

The Cummins 3100120 Idler Pulley plays a role in the operation of a truck by maintaining the tension and alignment of the belts within the engine’s accessory drive system. Proper tension and alignment are important for the efficient operation of components such as the alternator, water pump, and air conditioning compressor. The idler pulley helps to ensure these components receive consistent power transmission, which is important for their performance and durability 2.

Key Features

The Cummins 3100120 Idler Pulley is constructed from durable materials, designed to withstand the rigors of commercial truck operation. Its design includes precision-machined bearings for smooth operation and a robust housing that protects internal components from contaminants. Additionally, the pulley may feature a unique groove pattern on the pulley face to enhance belt grip and reduce slippage 3.

Benefits

The use of the Cummins 3100120 Idler Pulley can lead to several benefits. It contributes to improved belt life by maintaining optimal tension and alignment. This reduces the likelihood of belt failure and the need for frequent replacements. Additionally, proper belt tension and alignment can lead to reduced noise from the belt-driven system and enhanced overall system efficiency.

Installation

Installing the Cummins 3100120 Idler Pulley requires careful attention to ensure proper fitting and operation. The process involves removing the old pulley, cleaning the mounting area, and securing the new pulley in place. Tools such as a socket wrench and a torque wrench may be required. It is important to follow the manufacturer’s guidelines for torque specifications to ensure the pulley is properly secured without overtightening.

Troubleshooting

Common issues with idler pulleys include noise, belt slippage, and pulley seizing. Symptoms to watch for include unusual sounds from the belt area, a loose or slipping belt, or difficulty in starting the engine. Troubleshooting steps may involve inspecting the pulley for signs of wear, checking belt tension, and ensuring the pulley spins freely without resistance.

Maintenance

Regular maintenance of the Cummins 3100120 Idler Pulley is important for its longevity and performance. This includes periodic inspection for signs of wear or damage, ensuring the pulley is properly lubricated if required, and monitoring belt tension. Replacement should be considered if the pulley shows significant wear, if the belt frequently slips, or if noise from the belt area increases.

Cummins Corporation

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and reliability in the commercial truck industry. Its product range includes engines, powertrains, and related components, all designed to meet the demanding requirements of commercial applications.

Idler Pulley 3100120 Compatibility with Cummins Engines

The Idler Pulley part number 3100120, manufactured by Cummins, is designed to fit seamlessly with a range of Cummins engines. This part is integral to the engine’s operation, ensuring smooth and efficient functioning of the engine’s belt system.

VTA903 CM2250 V105

The VTA903 CM2250 V105 engine is one of the models that benefit from the 3100120 Idler Pulley. This part ensures that the belt system operates without any undue stress, maintaining the engine’s performance and longevity.

X12 CM2350 X119B

Similarly, the X12 CM2350 X119B engine also requires the 3100120 Idler Pulley for optimal performance. This part is engineered to fit precisely, providing the necessary support and alignment for the belt system in this engine model.

Grouping of Engines

The Idler Pulley 3100120 is compatible with both the VTA903 CM2250 V105 and the X12 CM2350 X119B engines. These engines, while distinct, share a commonality in their requirement for this specific idler pulley part. This compatibility ensures that maintenance and replacement parts are standardized, simplifying the process for technicians and operators.

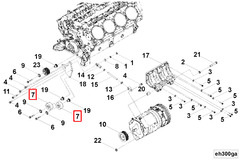

Role of Part 3100120 Idler Pulley in Engine Systems

The 3100120 Idler Pulley is an essential component in the efficient operation of various engine systems. It is strategically positioned within the engine’s accessory drive system to facilitate the smooth functioning of several key components.

Interaction with the Alternator

The Idler Pulley plays a significant role in maintaining the proper tension of the serpentine belt that drives the alternator. By adjusting the belt’s path, the Idler Pulley ensures that the alternator receives consistent power transmission. This consistent power is vital for the alternator to generate electricity, which is then used to charge the battery and power the vehicle’s electrical systems.

Coordination with the Refrigerant Compressor

In systems where air conditioning is present, the Idler Pulley assists in the operation of the refrigerant compressor. It helps in maintaining the correct belt tension and alignment, which is necessary for the compressor to function efficiently. This ensures that the air conditioning system can effectively cool the interior of the vehicle, providing a comfortable driving experience.

Support for Mounting Components

The Idler Pulley also interacts with various mounting components within the engine bay. Its placement and function are designed to support the structural integrity of the accessory drive system. By providing necessary tension and support to the serpentine belt, it indirectly supports the mounting of other accessories, ensuring they remain securely in place and operate within their designed parameters.

Conclusion

In summary, the 3100120 Idler Pulley is a pivotal element in the accessory drive system, enhancing the performance and reliability of the alternator, refrigerant compressor, and mounting components. Its role in maintaining belt tension and alignment is fundamental to the seamless operation of these engine systems.

-

Proceedings of the 5th Commercial Vehicle Technology Symposium CVT, Karsten Berns, Klaus Dressler, Patrick Fleischmann, Daniel Grges, Ralf Kalmar, Bernd Sauer, Nicole Stephan, Roman Teutsch, Martin Thul, Springer, 2018

↩ -

Automobile Vehicle Safety, George Peters, Barbara J Peters, CRC Press, 2002

↩ -

Fundamentals of Vehicle Dynamics, Thomas D. Gillespie, SAE International, 2021

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.