This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

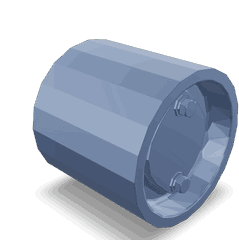

The Cummins 3092364 Idler Pulley is a component designed for use in commercial trucks. It serves a specific function within the truck’s belt drive system, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and significance is key to maintaining the truck’s performance and longevity.

Basic Concepts of Idler Pulleys

An idler pulley is a type of pulley that does not drive a machine part or accessory directly. Instead, it plays a role in maintaining the proper tension and alignment of the belt within a belt drive system. By supporting the belt and adjusting its path, the idler pulley ensures efficient power transmission and reduces wear on both the belt and the driven components 1.

Purpose of the 3092364 Idler Pulley

The Cummins 3092364 Idler Pulley is specifically designed to maintain the correct tension and alignment of the belt in a truck’s engine system. This ensures that the belt operates efficiently, transferring power to various engine components without slipping or misaligning. Proper tension and alignment are vital for the smooth operation of the engine and the longevity of the belt and related parts.

Key Features

The Cummins 3092364 Idler Pulley is constructed with high-quality materials to ensure durability and reliability. Its design includes precision-machined components that allow for smooth operation and minimal friction. The pulley is built to withstand the demanding conditions found in commercial truck applications, featuring a robust construction that supports its function within the engine system.

Benefits of Using the 3092364 Idler Pulley

Utilizing the Cummins 3092364 Idler Pulley offers several advantages. It contributes to improved belt life by maintaining optimal tension and alignment, which reduces the risk of belt failure. Additionally, it helps in reducing wear on other components by ensuring that the belt operates efficiently. This can lead to enhanced system efficiency and potentially lower maintenance costs over time.

Installation and Compatibility

Proper installation of the Cummins 3092364 Idler Pulley is crucial for its effective operation. The installation process involves securing the pulley in the correct position within the engine system, ensuring that it aligns properly with the belt and other components. Specific tools may be required for installation, and following manufacturer guidelines is recommended to ensure correct fitting.

Maintenance and Troubleshooting

Regular maintenance of the Cummins 3092364 Idler Pulley is important for its longevity and optimal performance. This includes checking the pulley for signs of wear or damage, ensuring that the belt tension remains within the recommended range, and addressing any issues promptly. Common problems may include belt slippage or unusual noises, which can often be resolved through adjustment or replacement of worn components.

Performance Under Various Conditions

The Cummins 3092364 Idler Pulley is designed to perform reliably under a range of operating conditions. It can handle varying temperatures, load conditions, and speeds, making it suitable for the demanding environments encountered by commercial trucks. Its robust construction and precise engineering allow it to maintain functionality and efficiency across different scenarios.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a broad product range, Cummins has established a strong reputation in the commercial truck industry. The company’s commitment to quality and performance is reflected in its parts, including the Cummins 3092364 Idler Pulley.

Idler Pulley Compatibility with Cummins Engines

The Idler Pulley part number 3092364, manufactured by Cummins, is designed to fit seamlessly with several engine models. This part plays a role in the engine’s operation by ensuring the proper tension and alignment of the engine’s belt system. Here is a detailed look at the compatibility of this idler pulley with specific Cummins engines:

QST30 CM2350 T101 and QST30 CM552

The Idler Pulley 3092364 is specifically engineered to fit the QST30 CM2350 T101 and QST30 CM552 engines. These engines are part of the Cummins QST30 series, known for their robust performance and reliability in various industrial applications. The idler pulley ensures that the belt system maintains the correct tension, which is essential for the efficient operation of the engine’s ancillary components, such as the alternator, water pump, and air conditioning compressor.

Ensuring Proper Fit and Function

When installing the Idler Pulley 3092364 in the QST30 CM2350 T101 and QST30 CM552 engines, it is important to follow the manufacturer’s guidelines to ensure a proper fit and function. This includes:

- Correct Alignment: Ensuring the idler pulley is correctly aligned with the belt system to prevent misalignment and potential belt slippage.

- Proper Tension: Adjusting the idler pulley to maintain the correct belt tension, which is critical for the longevity and performance of the engine.

- Secure Installation: Using the appropriate fasteners and ensuring the idler pulley is securely mounted to avoid any movement during engine operation.

By adhering to these guidelines, the Idler Pulley 3092364 will function optimally, contributing to the overall efficiency and reliability of the QST30 CM2350 T101 and QST30 CM552 engines.

Role of Part 3092364 Idler Pulley in Engine Systems

The part 3092364 Idler Pulley is a component in maintaining the efficiency and reliability of various engine systems. It primarily functions to adjust the tension of the drive belts that are integral to the operation of several engine-driven accessories.

Interaction with Belt Tensioner

The idler pulley works in conjunction with the belt tensioner to ensure that the drive belts are neither too loose nor too tight. Proper tension is vital for the efficient transfer of power from the engine to components such as the alternator, water pump, and air conditioning compressor. The idler pulley achieves this by applying the necessary force to keep the belt at the optimal tension, reducing wear and tear and enhancing the longevity of both the belt and the pulley itself.

Drive System Efficiency

In the drive system, the idler pulley plays a role in maintaining the alignment and stability of the drive belts. By providing additional support and guidance, it helps to minimize slippage and ensures that the belts run smoothly over the various pulleys and sprockets. This results in a more consistent and reliable operation of the driven components, which is essential for the overall performance of the engine.

Fan and Cooling System

The idler pulley is also a key component in the fan drive system. It assists in maintaining the correct tension of the belts that drive the fan, which is responsible for cooling the engine. Proper tension ensures that the fan operates efficiently, providing adequate airflow to prevent the engine from overheating. In systems with a fan drive idle assembly or a fan drive idler assembly, the idler pulley helps to manage the variable speed of the fan, optimizing cooling performance based on the engine’s operating conditions.

Comprehensive System Integration

Overall, the idler pulley is a versatile component that integrates seamlessly into various engine systems. Its ability to adjust belt tension and support the drive system makes it indispensable for the reliable operation of engine-driven accessories. Whether it’s ensuring the alternator generates sufficient power, the water pump circulates coolant effectively, or the air conditioning system operates smoothly, the idler pulley contributes to the harmonious functioning of the engine as a whole.

Conclusion

The Cummins 3092364 Idler Pulley is a critical component in the maintenance and operation of commercial truck engines. Its role in maintaining belt tension and alignment ensures the efficient transfer of power to engine accessories, contributing to the overall reliability and performance of the vehicle. Proper installation, maintenance, and understanding of its function are essential for maximizing the benefits of this Cummins part.

-

Harrison, Matthew. Controlling Noise and Vibration in Road Vehicles. SAE International, 2004.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.