This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

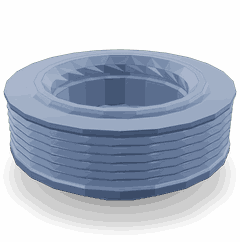

The Cummins 3072355 Idler Pulley is a component designed for use in commercial trucks. It serves a specific function within the truck’s belt-driven system, contributing to the efficient operation of various engine accessories. Understanding its purpose and significance is key to maintaining the overall performance and reliability of commercial vehicles.

Basic Concepts of Idler Pulleys

An idler pulley is a type of pulley used in belt-driven systems to maintain proper belt tension and alignment. It does not directly drive any component but instead supports the belt by guiding it around non-driving components. This ensures that the belt remains properly positioned and under the correct amount of tension, which is crucial for the efficient transfer of power to driven components such as the alternator, water pump, and air conditioning compressor 1.

Role of the 3072355 Idler Pulley in Truck Operation

This Cummins part plays a role in the operation of a truck by ensuring the serpentine belt remains correctly aligned and tensioned. This pulley interacts with the engine, alternator, and air conditioning compressor, among other components, to facilitate the smooth operation of these accessories. Proper alignment and tension of the belt are vital for the efficient functioning of these components, which in turn supports the overall performance of the truck 4.

Key Features of the 3072355 Idler Pulley

The design and construction of the 3072355 Idler Pulley incorporate several features that enhance its performance and durability. It is constructed using high-quality materials that are resistant to wear and corrosion. The pulley features precision-machined bearings that allow for smooth rotation, reducing friction and wear. Additionally, its design may include unique attributes such as a specific groove profile to accommodate the serpentine belt more effectively, contributing to its longevity and efficiency 5.

Benefits of Using the 3072355 Idler Pulley

Utilizing the 3072355 Idler Pulley offers several advantages. It contributes to improved belt life by maintaining optimal tension and alignment. This reduces the likelihood of belt slippage and premature wear. Additionally, the smooth operation of the pulley minimizes noise and vibration, leading to a quieter and more comfortable driving experience. Enhanced system efficiency is another benefit, as the pulley ensures that power is effectively transferred to the driven components, supporting the truck’s overall performance 2.

Installation Considerations

When installing the 3072355 Idler Pulley, it is important to follow guidelines and best practices to ensure proper function. This includes aligning the pulley correctly within the belt system, adhering to specified torque values for fastening, and performing any necessary preparatory steps such as cleaning the mounting area. Proper installation is key to the pulley’s performance and the longevity of the belt system 3.

Troubleshooting Common Issues

Common problems associated with idler pulleys include noise, wear, and belt slippage. Diagnosing these issues involves inspecting the pulley for signs of damage or misalignment, checking the condition of the belt, and ensuring that the pulley is properly tensioned. Solutions may range from adjusting the belt tension to replacing worn components, depending on the specific issue identified 4.

Maintenance Recommendations

Routine maintenance of the 3072355 Idler Pulley involves regular inspection for signs of wear, ensuring that the belt remains properly tensioned, and lubricating the pulley’s bearings as recommended. Inspection intervals should be aligned with the truck’s maintenance schedule, and any signs of excessive wear or damage should be addressed promptly to prevent further issues 5.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. Its product range includes a variety of components and systems designed to enhance the performance, efficiency, and reliability of commercial vehicles.

Idler Pulley Part 3072355 Compatibility with Cummins Engines

The Idler Pulley part number 3072355, manufactured by Cummins, is designed to fit a variety of Cummins engines. This part plays a role in the engine’s belt drive system, ensuring proper tension and alignment of the serpentine belt. Below is a detailed breakdown of the engines with which this idler pulley is compatible:

G855 Series

- G855

- G855 CM558

- GTA855 CM558 (CM2358)

- G101

These engines, part of the G855 series, are known for their robust design and efficiency. The 3072355 idler pulley is engineered to fit seamlessly within the belt drive systems of these engines, ensuring optimal performance and longevity.

N14 Series

- N14 CELECT PLUS

- N14 G

- N14 MECHANICAL

The N14 series engines, including the CELECT PLUS, G, and MECHANICAL variants, benefit from the precise fit and functionality of the 3072355 idler pulley. This part is crucial for maintaining the correct tension and alignment of the serpentine belt, which is essential for the efficient operation of these engines.

NH/NT 855 Series

- NH/NT 855

The NH/NT 855 engines are another series where the 3072355 idler pulley is a perfect fit. This part ensures that the belt drive system operates smoothly, contributing to the overall reliability and performance of the engine.

QSN14 Series

- QSN14 CM876 N103

The QSN14 CM876 N103 engine is designed for heavy-duty applications, and the 3072355 idler pulley is engineered to meet the demands of such environments. This part ensures that the belt drive system remains efficient and reliable, even under strenuous conditions.

By ensuring a precise fit and optimal performance, the 3072355 idler pulley is a component for maintaining the functionality and longevity of these Cummins engines.

Role of Part 3072355 Idler Pulley in Engine Systems

The idler pulley, specifically part 3072355, is an integral component in the efficient operation of various engine systems. It primarily functions to maintain the proper tension of the belt that drives multiple engine components.

In systems involving the water pump, the idler pulley ensures that the belt remains taut, allowing for the consistent operation of the water pump. This is essential for the circulation of coolant throughout the engine, which helps in maintaining optimal engine temperature.

When considering the water and idler pump setup, the idler pulley’s role becomes even more pronounced. It not only assists in maintaining belt tension but also helps in the smooth operation of both the water pump and the idler mechanism. This setup is often found in engines where space is at a premium, and the idler pulley helps in routing the belt in a compact manner.

In more complex engine bases that incorporate multiple driven components, the idler pulley part 3072355 is employed to adjust the path of the belt. This allows for the efficient transfer of power to components such as the alternator, air conditioning compressor, and power steering pump, in addition to the water pump.

Overall, the idler pulley is a versatile component that enhances the reliability and performance of engine systems by ensuring that driven components receive consistent power transmission via the belt.

Conclusion

The Cummins 3072355 Idler Pulley is a critical component in the maintenance and operation of commercial trucks and various Cummins engines. Its role in maintaining belt tension and alignment ensures the efficient operation of engine accessories, contributing to the overall performance and reliability of the vehicle. Proper installation, maintenance, and understanding of its function are essential for maximizing the benefits of this part.

-

The Motor Vehicle, TK Garrett, K Newton, W Steeds, Reed Educational and Professional Publishing Ltd, 2001

↩ -

Fuel Consumption and Consumption Optimization, Second Edition, Michael Hilgers, Springer Nature, 2023

↩ -

B4.5 CM2350 B146C, Service Manual (5504283)

↩ -

Brakes Brake Control and Driver Assistance Systems Function Regulation and Components, Konrad Reif Ed, Springer, 2014

↩ ↩ -

Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings, Dominique Bonneau, Aurelian Fatu and Dominique Souchet, Wiley-ISTE, 2014

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.