This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3062696 Idler Pulley Adjuster is a component designed to maintain optimal tension in the belt drive system of heavy-duty trucks. It ensures that the belts driving various components, such as the alternator, A/C compressor, and power steering pump, remain properly tensioned, contributing to the efficient and reliable operation of these components 1.

Basic Concepts of Idler Pulley Adjusters

An idler pulley adjuster is a device used within the belt drive system to maintain the correct tension on the belts. It operates by adjusting the position of the idler pulley, which in turn keeps the belt at the proper tension. This is essential for the efficient transfer of power from the engine to the driven components, ensuring they operate smoothly and effectively 2.

Role of the 3062696 Idler Pulley Adjuster in Truck Operation

The 3062696 Idler Pulley Adjuster plays a specific role in the truck’s belt drive system by interacting with other components such as the alternator, A/C compressor, and power steering pump. It ensures that the belts remain taut, which is necessary for these components to function correctly. By maintaining the right tension, the adjuster helps in the efficient operation of the alternator to generate electricity, the A/C compressor to cool the cabin, and the power steering pump to assist in steering the vehicle 3.

Key Features of the 3062696 Idler Pulley Adjuster

The design and construction of the 3062696 Idler Pulley Adjuster include several features that enhance its performance and durability. It is typically made from high-quality materials that can withstand the rigors of heavy-duty truck operation. The build quality ensures that it can maintain consistent belt tension under varying conditions. Additionally, it may include unique attributes such as a self-adjusting mechanism that automatically maintains the correct tension, reducing the need for manual adjustments 4.

Benefits of Using the 3062696 Idler Pulley Adjuster

Using the 3062696 Idler Pulley Adjuster provides several advantages. It helps in maintaining improved belt tension, which reduces the likelihood of belt slippage and the associated wear on driven components. This leads to enhanced overall system efficiency, as the components can operate more smoothly and reliably. Additionally, proper belt tension contributes to the longevity of the belts and the components they drive, resulting in reduced maintenance costs and improved truck performance 5.

Troubleshooting Common Issues with Idler Pulley Adjusters

Identifying and addressing common problems associated with idler pulley adjusters is important for maintaining truck performance. Symptoms of failure may include unusual noises from the belt area, visible belt wear, or components not functioning correctly. Diagnostic procedures may involve inspecting the adjuster for signs of wear or malfunction, checking the belt tension, and ensuring that the adjuster is properly aligned. Potential solutions could range from simple adjustments to replacement of the adjuster if it is found to be faulty 6.

Maintenance Tips for Idler Pulley Adjusters

Routine maintenance practices are recommended to ensure the longevity and reliable performance of the 3062696 Idler Pulley Adjuster. This includes regular inspection intervals to check for signs of wear or damage, ensuring that the adjuster is properly lubricated to reduce friction and wear, and following manufacturer guidelines for replacement criteria. Proper maintenance helps in preventing unexpected failures and ensures that the adjuster continues to perform its function effectively 7.

Cummins: A Brief Overview

Cummins Inc. is a well-established company in the automotive and heavy-duty truck industry, known for its commitment to quality and innovation. Founded in 1919, Cummins has a long history of producing reliable and high-performance engines and components. Its product range includes engines, filtration systems, emissions solutions, and aftermarket parts, all designed to meet the demanding requirements of heavy-duty applications. Cummins’ reputation for quality is built on its dedication to engineering excellence and customer satisfaction 8.

Idler Pulley Adjuster Part 3062696 Compatibility with Cummins Engines

The Idler Pulley Adjuster part number 3062696, manufactured by Cummins, is a critical component in maintaining the proper tension of the engine’s accessory belt. This part is designed to fit seamlessly with various Cummins engine models, ensuring optimal performance and longevity of the belt system.

N14 CELECT Engine

In the N14 CELECT engine, the Idler Pulley Adjuster part 3062696 plays a vital role in the engine’s belt-driven accessory system. This engine variant is known for its electronic control system, which enhances fuel efficiency and reduces emissions. The adjuster helps maintain the correct tension on the accessory belt, which drives essential components such as the alternator, water pump, and air conditioning compressor. Proper tension ensures these components operate efficiently and prevents belt slippage, which can lead to premature wear and failure 9.

N14 MECHANICAL Engine

Similarly, in the N14 MECHANICAL engine, the Idler Pulley Adjuster part 3062696 is integral to the engine’s belt-driven accessory system. This engine variant relies on a mechanical control system, which, while less complex than the CELECT version, still requires precise belt tension for optimal performance. The adjuster ensures that the belt remains taut, which is crucial for the efficient operation of the alternator, water pump, and other belt-driven accessories. This helps maintain the engine’s overall health and reliability 10.

Grouping the Engines

Both the N14 CELECT and N14 MECHANICAL engines benefit from the use of the Idler Pulley Adjuster part 3062696. Despite their differences in control systems, the fundamental requirement for maintaining proper belt tension remains the same. This part is designed to fit both engine variants, ensuring that the accessory belt operates within the manufacturer’s specifications. This compatibility allows for easier maintenance and repair, as the same part can be used across different engine models, reducing inventory needs and simplifying the repair process 11.

Role of Part 3062696 Idler Pulley Adjuster in Engine Systems

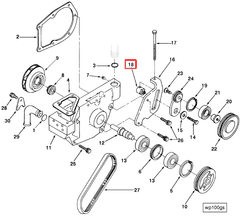

The idler pulley adjuster (part 3062696) is a critical component in maintaining the proper tension and alignment of the idler assembly within engine systems. This adjuster ensures that the idler pulley operates efficiently by providing the necessary tension to the belt that drives various engine components.

In the context of the idler assembly, the idler pulley adjuster works in conjunction with the idler pulley mounting to keep the belt taut. This is important for the smooth operation of the engine, as a loose belt can lead to slippage, increased wear, and potential damage to other components.

When considering the water pump, the idler pulley adjuster plays a significant role. The water pump relies on a driven belt to operate, and consistent tension is required to ensure it functions correctly. The adjuster helps maintain this tension, allowing the water pump to circulate coolant effectively through the engine, preventing overheating and ensuring optimal engine performance.

Overall, the idler pulley adjuster is a key component in the interplay between the idler assembly, idler pulley mounting, and water pump, contributing to the reliable and efficient operation of the engine system 12.

Conclusion

The Cummins 3062696 Idler Pulley Adjuster is a vital component in the maintenance and operation of heavy-duty truck belt drive systems. By ensuring proper belt tension, it contributes to the efficient and reliable operation of critical engine components. Regular maintenance and proper troubleshooting are essential to maximize the performance and longevity of this part.

-

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ -

Lakshminarayanan, P. A., & Agarwal, A. K. (2019). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer.

↩ -

Department of Energy. (2015). Department of Energy Fundamentals Handbook. Department of Energy.

↩ -

Huang, M. (2002). Vehicle Crash Dynamics. CRC Press.

↩ -

Cummins Inc. (2021). ISV5.0 CM3230 V104 Service Manual (4367291).

↩ -

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ -

Lakshminarayanan, P. A., & Agarwal, A. K. (2019). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer.

↩ -

Department of Energy. (2015). Department of Energy Fundamentals Handbook. Department of Energy.

↩ -

Cummins Inc. (2021). ISV5.0 CM3230 V104 Service Manual (4367291).

↩ -

Cummins Inc. (2021). ISV5.0 CM3230 V104 Service Manual (4367291).

↩ -

Cummins Inc. (2021). ISV5.0 CM3230 V104 Service Manual (4367291).

↩ -

Cummins Inc. (2021). ISV5.0 CM3230 V104 Service Manual (4367291).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.