This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3056090 Idler Pulley is a component designed for use in commercial trucks. It serves a specific function within the vehicle’s belt drive system, contributing to the efficient operation of various engine components. Understanding its role and significance can help in maintaining the overall performance and reliability of the truck.

Basic Concepts of Idler Pulleys

An idler pulley is a type of pulley used in belt drive systems to maintain proper tension and alignment of the drive belts. It does not directly drive any component but instead supports the belt by providing a means to adjust tension and ensure the belt runs smoothly and efficiently over other pulleys connected to driven components 1.

Purpose of the Cummins 3056090 Idler Pulley

The Cummins 3056090 Idler Pulley plays a role in the belt drive system of a truck by maintaining the correct tension on the belts that drive accessories such as the alternator, water pump, and air conditioning compressor. By ensuring the belt remains properly tensioned and aligned, it helps in the efficient transfer of power from the engine to these accessories, thereby contributing to the overall performance of the truck’s engine system 2.

Key Features

The Cummins 3056090 Idler Pulley is designed with specific features to enhance its performance and durability. It is constructed from high-quality materials that can withstand the rigors of commercial truck operation. Its design includes precision-machined surfaces to ensure smooth operation and longevity. Additionally, it may feature unique characteristics such as a self-aligning bearing to accommodate minor misalignments and reduce wear 3.

Benefits of Using the Cummins 3056090 Idler Pulley

Using the Cummins 3056090 Idler Pulley offers several advantages. It provides improved belt tension, which is crucial for the efficient operation of the belt drive system. This results in reduced wear on drive components and enhances the overall efficiency of the truck’s engine system. The high-quality construction and design of the pulley contribute to its durability and reliability under demanding conditions 4.

Installation Considerations

Proper installation of the Cummins 3056090 Idler Pulley is important to ensure correct fitting and operation. This may involve prerequisites such as ensuring the engine is cool and the belt drive system is free of debris. Tools required for installation may include a socket wrench and a tension gauge to ensure the belt is properly tensioned. Following the manufacturer’s instructions for installation will help in achieving optimal performance and longevity of the pulley.

Troubleshooting Common Issues

Common problems associated with idler pulleys include noise, belt slippage, or pulley seizing. These issues can often be diagnosed by visual inspection or by listening for unusual sounds during operation. Resolving these issues may involve adjusting the belt tension, replacing worn components, or lubricating moving parts as necessary.

Maintenance Tips

Regular maintenance practices can help ensure the longevity and optimal performance of the Cummins 3056090 Idler Pulley. This includes inspecting the pulley and belt for signs of wear or damage at regular intervals, ensuring proper belt tension, and lubricating moving parts as recommended by the manufacturer. Addressing any issues promptly can help prevent more serious problems down the line.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance components. Their product range includes a variety of engine and component solutions designed to meet the demanding requirements of commercial vehicles.

Idler Pulley Part 3056090 Compatibility with Cummins Engines

The Idler Pulley part number 3056090, manufactured by Cummins, is designed to be compatible with a range of Cummins engines, including the N14 CELECT and N14 MECHANICAL models. This pulley plays a role in the engine’s belt-driven systems, ensuring that the belts operate smoothly and efficiently.

For the N14 CELECT and N14 MECHANICAL engines, the 3056090 Idler Pulley is engineered to fit seamlessly into the engine’s belt routing system. This ensures that the belts maintain proper tension and alignment, which is vital for the engine’s performance and longevity. The design of the 3056090 Idler Pulley allows it to work effectively in both electronic and mechanical configurations of the N14 engine, providing a reliable solution for maintaining belt integrity.

In both the N14 CELECT and N14 MECHANICAL engines, the 3056090 Idler Pulley is positioned in such a way that it supports the engine’s ancillary systems, including the alternator, air compressor, and water pump. This ensures that these systems operate without interruption, contributing to the overall efficiency and reliability of the engine.

By using the 3056090 Idler Pulley, technicians and operators can expect consistent performance and reduced maintenance needs, as the pulley is built to withstand the rigors of continuous operation in demanding environments.

Role of Part 3056090 Idler Pulley in Engine Systems

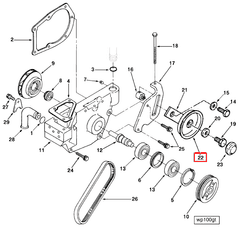

The idler pulley, specifically part 3056090, is integral to the smooth operation of various engine systems. It is a key component in maintaining the tension and alignment of belts that drive multiple auxiliary components.

In the context of the EBM-Pump system, the idler pulley ensures that the belt driving the pump remains taut. This is essential for the efficient transfer of power from the engine to the pump, which in turn ensures consistent water circulation. Proper tensioning by the idler pulley prevents slippage, which could lead to inefficient pump operation and potential overheating of the engine.

When considering the Water System, the idler pulley’s role becomes even more apparent. The water pump, driven by the belt, relies on consistent tension to maintain optimal flow rates. The idler pulley, as part of the idler assembly, helps in adjusting this tension dynamically as the engine operates under varying loads.

Additionally, the idler pulley is part of the Pulley Support Assembly. This assembly is designed to provide a stable and adjustable mounting point for the idler pulley. The support assembly allows for fine-tuning of belt tension, which is vital for the longevity and performance of both the belt and the driven components, such as the water pump.

In summary, part 3056090 idler pulley is a fundamental component in ensuring that the belts driving the EBM-Pump and water systems operate under the correct tension. This not only enhances the efficiency of these systems but also contributes to the overall reliability and performance of the engine.

Conclusion

The Cummins 3056090 Idler Pulley is a critical component in the belt drive system of commercial trucks, ensuring the efficient operation of engine accessories. Its high-quality construction, precise design, and compatibility with various Cummins engines make it a reliable choice for maintaining the performance and reliability of truck engines. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part.

-

Boyce, Meherwan P. Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing, 2002.

↩ -

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International, 2023.

↩ -

Kluczyk, Barry. How to Rebuild Any Automotive Engine. CarTech, 2008.

↩ -

Giles, Tim. Automotive Engines Diagnosis Repair and Rebuilding. Cengage Learning, 2019.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.