This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

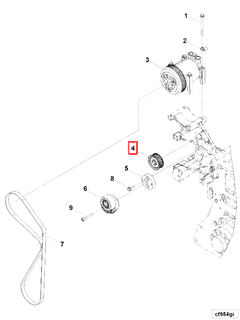

The 2874073 Idler Pulley, manufactured by Cummins, is a vital component in the commercial vehicle industry, contributing to the efficiency and reliability of truck engines and accessory systems.

Basic Concepts of Idler Pulleys

An idler pulley supports and guides a belt within a belt-driven system, maintaining proper belt tension and alignment for efficient power transmission 1. It rotates as the belt moves over it, reducing belt slack and wear on other parts of the system.

Role of the 2874073 Idler Pulley in Truck Operation

This Cummins part maintains the correct tension and alignment of belts driving various engine accessories, such as the alternator, water pump, and air conditioning compressor, ensuring efficient operation and longevity of the truck’s engine and accessory systems 2.

Key Features of the 2874073 Idler Pulley

Designed with high-quality materials and construction techniques, the 2874073 features a robust bearing system for smooth rotation, reducing friction and wear. It is constructed from materials that resist corrosion and wear, enhancing its longevity in demanding environments 3.

Benefits of Using the 2874073 Idler Pulley

Utilizing this part offers improved belt tension, leading to more efficient power transmission and reduced wear on the belt and other components. It also contributes to enhanced engine performance and reliability, with durable construction meaning less frequent replacements 4.

Installation and Compatibility

Proper installation of the 2874073 Idler Pulley is crucial for its effective operation. It is important to follow manufacturer guidelines to ensure it is correctly positioned and secured. Compatibility with the truck’s make and model is also vital, as this ensures the pulley fits properly and functions as intended within the truck’s engine system 5.

Troubleshooting Common Issues

Common issues associated with idler pulleys include noise, vibration, or belt slippage. These problems can often be traced back to improper installation, wear and tear, or misalignment. Troubleshooting steps may involve inspecting the pulley and belt for signs of wear, ensuring the pulley is correctly aligned and tensioned, and replacing any worn or damaged components 6.

Maintenance Tips

Regular maintenance of the 2874073 Idler Pulley is key to its longevity and performance. This includes periodic inspections for signs of wear or damage, cleaning the pulley and surrounding areas to prevent buildup of dirt and debris, and replacing the pulley if it shows significant wear or if the belt tension cannot be adequately maintained 7.

Cummins: A Brief Overview

Cummins Inc. is a leader in the commercial vehicle industry, known for its wide range of high-quality diesel engines and components. With a history of innovation and commitment to quality, Cummins has established a strong reputation for manufacturing reliable and efficient automotive components. The company’s dedication to excellence is evident in its product offerings, including the 2874073 Idler Pulley 8.

Idler Pulley 2874073 Compatibility with Cummins Engines

The Idler Pulley part number 2874073 is designed to fit seamlessly with a range of Cummins engines. This part is crucial for maintaining the proper tension and alignment of the engine’s accessory belts, ensuring efficient operation and longevity of the engine components.

ISZ13 CM2150 Z105 and QSZ13 CM2150 Z102

The Idler Pulley 2874073 is compatible with both the ISZ13 CM2150 Z105 and QSZ13 CM2150 Z102 engines. These engines, while sharing some common features, may have slight variations in their configurations. The idler pulley is engineered to adapt to these differences, providing a reliable fit and function across both engine models.

Ensuring that the idler pulley is correctly aligned and tensioned helps to prevent belt slippage, which can lead to reduced efficiency and potential damage to the engine’s components. The design of the 2874073 idler pulley is such that it can accommodate the specific requirements of both the ISZ13 CM2150 Z105 and QSZ13 CM2150 Z102 engines, making it a versatile and essential part for these engine models 9.

Role of Part 2874073 Idler Pulley in Engine Systems

The 2874073 Idler Pulley is integral to the proper functioning of compressors and refrigerant systems, ensuring efficient power transmission, consistent refrigerant flow, and reduced component wear. It maintains the proper tension of the belt that drives the compressor, ensuring consistent power transmission from the engine to the compressor. This tension is vital for the compressor to operate efficiently, as it ensures consistent power transmission from the engine to the compressor. Without adequate tension, the belt may slip, leading to inefficient compressor operation and potential damage to the belt or compressor itself 10.

Furthermore, in systems where refrigerant circulation is managed, the idler pulley contributes to the stable functioning of the refrigerant pump or compressor. By keeping the drive belt taut, it ensures that the pump receives a consistent drive force. This consistency is important for maintaining the correct flow of refrigerant, which is essential for effective cooling and climate control within the engine system 11.

Additionally, the idler pulley helps in reducing wear and tear on the belt and other components by distributing the load evenly. This even distribution prevents excessive stress on any single point, prolonging the lifespan of the belt and enhancing the overall reliability of the engine system 12.

Conclusion

The 2874073 Idler Pulley by Cummins is a critical component for maintaining the efficiency and reliability of commercial truck engines and accessory systems. Its role in maintaining proper belt tension and alignment, along with its durable construction, ensures efficient power transmission and longevity of engine components. Regular maintenance and proper installation are key to maximizing the benefits of this part.

-

Parikyan, T. (Ed.). (2022). Advances in Engine and Powertrain Research and Technology. Springer Nature.

↩ -

Lakshminarayanan, P. A., & Aghav, Y. V. (2010). Modelling Diesel Combustion. Springer Science.

↩ -

Sheng, G. (2012). Vehicle Noise, Vibration and Sound Quality. SAE International.

↩ -

Wharton, A. J. (1991). Diesel Engines. Butterworth-Heinemann Ltd.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for QSV91-G4 CM558/CM700 V102. Bulletin Number 4326109.

↩ -

Parikyan, T. (Ed.). (2022). Advances in Engine and Powertrain Research and Technology. Springer Nature.

↩ -

Sheng, G. (2012). Vehicle Noise, Vibration and Sound Quality. SAE International.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for QSV91-G4 CM558/CM700 V102. Bulletin Number 4326109.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for QSV91-G4 CM558/CM700 V102. Bulletin Number 4326109.

↩ -

Lakshminarayanan, P. A., & Aghav, Y. V. (2010). Modelling Diesel Combustion. Springer Science.

↩ -

Wharton, A. J. (1991). Diesel Engines. Butterworth-Heinemann Ltd.

↩ -

Sheng, G. (2012). Vehicle Noise, Vibration and Sound Quality. SAE International.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.