This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

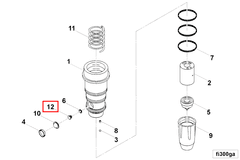

The Cummins Injector Orifice Plug, part number 3045004, is a critical component in heavy-duty truck fuel injection systems. This part is designed to regulate the flow of fuel into the combustion chamber, ensuring efficient and effective engine operation 1.

Function and Operation

The Injector Orifice Plug operates within the fuel injection system by controlling the rate of fuel delivery to the engine’s combustion chamber. It precisely meters the fuel flow, which is essential for maintaining the correct fuel-to-air ratio for optimal combustion. This, in turn, affects the engine’s power output and fuel efficiency. The plug’s design allows it to withstand the high pressures and temperatures present in the fuel injection system, ensuring reliable operation over time 2.

Purpose of the Injector Orifice Plug

In the fuel injection process, the Injector Orifice Plug ensures that fuel is atomized correctly before it enters the combustion chamber. Proper atomization is key to achieving efficient combustion, which leads to better engine performance and reduced emissions. By regulating fuel flow and pressure, the plug contributes to the engine’s overall efficiency and longevity 3.

Key Features

The Injector Orifice Plug 3045004 is characterized by its durable material composition, designed to resist the corrosive effects of diesel fuel and the high temperatures within the engine. Its design includes precise orifice sizing to ensure accurate fuel metering. Additionally, the plug is engineered with a focus on ease of installation and maintenance, featuring a straightforward design that simplifies replacement and servicing.

Benefits

The advantages of using the Injector Orifice Plug 3045004 include improved fuel atomization, leading to more efficient combustion and enhanced engine performance. This can result in better fuel economy and reduced emissions. For fleet operators, the plug’s durability and reliability can lead to cost savings by minimizing the need for frequent replacements and repairs.

Installation and Maintenance

Proper installation of the Injector Orifice Plug involves ensuring that it is correctly seated within the fuel injector to prevent leaks and ensure optimal performance. Tools required for installation may include torque wrenches to achieve the correct tightening specifications. Maintenance tips include regular inspection for signs of wear or damage, and replacement according to the manufacturer’s recommendations or when performance issues arise.

Troubleshooting Common Issues

Common problems associated with the Injector Orifice Plug may include leaks or blockages, which can affect fuel delivery and engine performance. Troubleshooting steps may involve inspecting the plug for damage, cleaning or replacing it if necessary, and ensuring that it is correctly installed. Addressing these issues promptly can help maintain engine efficiency and prevent more significant problems.

Manufacturer Overview - Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established itself as a pioneer in diesel engine technology, committed to innovation and sustainability in the automotive industry. Their expertise in engine design and manufacturing is reflected in the quality and reliability of components like the Injector Orifice Plug 3045004.

Cummins Injector Orifice Plug (Part 3045004) in N14 MECHANICAL Engines

The Cummins Injector Orifice Plug, identified by part number 3045004, is a critical component in the N14 MECHANICAL engine series. This part plays a pivotal role in the engine’s fuel injection system, ensuring that the injectors operate efficiently and effectively. The injector orifice plug is designed to seal the orifice in the injector, preventing any leakage or contamination that could affect the engine’s performance.

In the N14 MECHANICAL engine, the injector orifice plug is integral to maintaining the precision of the fuel injection process. This engine is known for its robust design and is often utilized in heavy-duty applications, where reliability and performance are paramount. The injector orifice plug’s role in this context is to ensure that the fuel is delivered to the combustion chamber in the correct quantity and at the right time, which is essential for the engine’s overall efficiency and longevity.

The injector orifice plug’s compatibility extends to various configurations within the N14 MECHANICAL engine family, ensuring that it can be used across different models and specifications. This versatility makes it a valuable component for technicians and engineers working with these engines, as it can be applied in multiple scenarios without the need for specific engine modifications.

Given its importance, the injector orifice plug must be of high quality and precision-engineered to meet the stringent demands of the N14 MECHANICAL engine. Cummins, as a leading manufacturer of diesel engines, ensures that this part adheres to rigorous standards, providing users with a reliable and durable solution for their engine maintenance needs.

Understanding the Role of Part 3045004 Injector Orifice Plug in Engine Systems

The Injector Orifice Plug 3045004 is an essential component in various engine systems, ensuring the proper functioning and efficiency of fuel delivery and management. Here’s how it integrates with the provided components:

EBM:System

In the Engine Bay Management (EBM) system, the Injector Orifice Plug plays a significant role in maintaining the integrity of the fuel injection process. It ensures that the fuel is delivered consistently and precisely to the combustion chamber, which is vital for the EBM system’s overall performance. The plug helps in regulating the fuel flow, preventing leaks, and ensuring that the fuel injectors operate within their specified parameters.

ETR Engine

For the Electronically Controlled Turbocharged Rail (ETR) engine, the Injector Orifice Plug is integral to the fuel injection system. It helps in maintaining the correct fuel pressure and flow rate, which is essential for the turbocharging process. The plug ensures that the fuel injectors deliver the right amount of fuel at the right time, optimizing the engine’s power output and fuel efficiency.

Fuel Pump Code

In systems where a fuel pump code is utilized, the Injector Orifice Plug assists in fine-tuning the fuel delivery. It works in conjunction with the fuel pump to ensure that the fuel is delivered at the correct pressure and volume. This is particularly important in systems where the fuel pump code is used to adjust fuel delivery based on engine load and operating conditions.

Solenoid Plumbing

When integrated with solenoid plumbing, the Injector Orifice Plug enhances the precision of fuel delivery. The solenoid valves control the opening and closing of fuel passages, and the plug ensures that the fuel flow is consistent and free from disruptions. This integration is key in systems where precise fuel metering is required for optimal engine performance.

Throttle Fuel Manifold Multi

In a Throttle Fuel Manifold Multi system, the Injector Orifice Plug contributes to the efficient distribution of fuel across multiple cylinders. It ensures that each injector receives the correct amount of fuel, which is critical for balanced combustion and smooth engine operation. The plug helps in preventing fuel leaks and maintaining the integrity of the fuel manifold system.

Conclusion

The Cummins Injector Orifice Plug 3045004 is a vital component in heavy-duty truck fuel injection systems. Its role in regulating fuel flow, ensuring proper atomization, and maintaining engine efficiency cannot be overstated. With its durable design, ease of installation, and compatibility across various engine systems, this Cummins part is essential for maintaining optimal engine performance and longevity.

-

Advanced Automotive Electricity and Electronics, Michael Klyde and Kirk VanGelder, Jones Bartlett Learning, 2010.

↩ -

Charging the Internal Combustion Engine, Hermann Hiereth, Peter Prenninger and Klaus W Drexl, Springer, 2010.

↩ -

Heavy Duty Truck Systems Fifth Edition, Sean Bennett, Ian Andrew Norman, Delmar Cengage Learning, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.