3694415

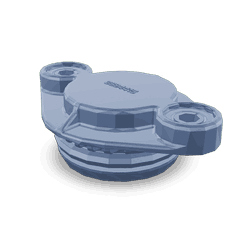

O-Ring Plug

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3694415 O-Ring Plug is a component designed for use in heavy-duty truck maintenance and operation. It serves a specific function within the truck’s system, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and significance is key to maintaining the truck’s performance and longevity.

Basic Concepts of O-Ring Plugs

O-Ring Plugs are mechanical components used to seal openings in systems where fluid or gas leakage needs to be prevented. They operate by creating a tight seal when compressed within a groove, effectively blocking the passage of fluids or gases. This sealing mechanism is vital in maintaining the integrity of the system and ensuring that the vehicle operates efficiently 1.

Purpose of the Cummins 3694415 O-Ring Plug

This Cummins part plays a role in sealing specific areas within a truck’s engine or system. It is designed to prevent the leakage of fluids or gases, thereby maintaining the system’s pressure and efficiency. Its location within the engine or system is critical to its function, as it must be positioned where sealing is most needed to prevent any potential leaks that could affect the vehicle’s performance 2.

Key Features

The Cummins 3694415 O-Ring Plug is characterized by its material composition, which is typically made from durable elastomers to withstand high temperatures and pressures. Its design includes precise dimensions to ensure a snug fit within the designated groove, enhancing its sealing capabilities. Additionally, it may possess unique attributes such as resistance to specific chemicals or oils, further improving its performance and durability in various operating conditions 3.

Benefits of Using the Cummins 3694415 O-Ring Plug

Utilizing this Cummins part offers several advantages. It provides improved sealing efficiency, which is crucial for maintaining system pressure and preventing leaks. Its durability ensures longevity, reducing the frequency of replacements. Moreover, its resistance to various operating conditions, including extreme temperatures and exposure to chemicals, enhances its reliability and performance 4.

Installation and Replacement Guidelines

Proper installation of the Cummins 3694415 O-Ring Plug involves ensuring the groove is clean and free of debris before inserting the plug. It should be compressed evenly within the groove to achieve an effective seal. Replacement guidelines suggest inspecting the plug regularly for signs of wear or damage and replacing it as necessary to maintain system integrity. Tools required may include groove cleaners and lubricants to facilitate installation 5.

Troubleshooting Common Issues

Common issues with O-Ring Plugs, such as leaks or failure, can often be traced back to improper installation, wear and tear, or exposure to incompatible fluids or gases. Troubleshooting steps include inspecting the plug and groove for damage, ensuring proper fit and compression, and verifying compatibility with the system’s fluids or gases. Addressing these issues promptly can prevent more significant problems and maintain the vehicle’s performance 6.

Maintenance Tips

Regular maintenance of the Cummins 3694415 O-Ring Plug involves periodic inspection for signs of wear, damage, or leakage. Cleaning the plug and groove as part of routine maintenance can prevent debris buildup, which may compromise the seal. Replacement should be considered if the plug shows significant wear or if leaks are detected, ensuring the system’s continued efficiency and reliability 7.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the automotive and heavy-duty truck industry. Its product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of various applications 8.

Role of Part 3694415 O-Ring Plug in Engine Systems

This part is integral to maintaining the integrity and efficiency of various engine systems. In the context of the arrangement component, this O-Ring Plug ensures that the sealing between different sections of the engine is maintained, preventing any unwanted leaks or seepages that could compromise engine performance. Its placement is carefully designed to withstand the pressures and temperatures typical in engine operations, ensuring a consistent and reliable seal.

In the oil fill system, the O-Ring Plug plays a significant role by securing the oil fill cap or any associated fittings. This ensures that the engine oil remains contained within the system, preventing any loss that could lead to inadequate lubrication. Proper lubrication is essential for reducing friction between moving parts, thereby enhancing engine longevity and performance. The O-Ring Plug’s ability to create a tight seal is vital in maintaining the correct oil levels, which are monitored during routine maintenance checks 9.

Conclusion

The Cummins 3694415 O-Ring Plug is a critical component in maintaining the efficiency and reliability of heavy-duty truck engines. Its role in sealing various engine components prevents leaks, ensures proper lubrication, and contributes to the overall performance and longevity of the vehicle. Regular maintenance and proper installation are essential to maximize the benefits of this part.

-

Ling, Frederick F. The Automotive Body. Springer Science, 2011.

↩ -

Genta, Giancarlo, and Lorenzo Morello. The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition. Springer, 2019.

↩ -

Atkins, Richard D. An Introduction to Engine Testing and Development. SAE International, 2009.

↩ -

Fijalkowski, BT. Automotive Mechatronics Operational and Practical Issues Volume 1. Springer, 2011.

↩ -

Cummins Inc. Marine C Command HD Panel System, Bulletin Number 4332831, Master Repair Manual.

↩ -

Ling, Frederick F. The Automotive Body. Springer Science, 2011.

↩ -

Genta, Giancarlo, and Lorenzo Morello. The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition. Springer, 2019.

↩ -

Cummins Inc. Company Overview. Available at: https://www.cummins.com/company/overview

↩ -

Atkins, Richard D. An Introduction to Engine Testing and Development. SAE International, 2009.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.