This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

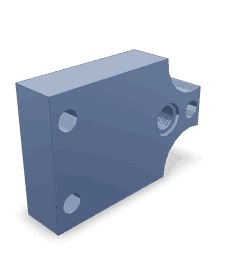

The Cummins 3164002 Mounting Plate is a critical component in heavy-duty truck applications, designed to support the secure attachment of various engine components. This part ensures structural integrity and proper alignment, contributing to the vehicle’s overall efficiency and performance.

Purpose and Function

This Cummins part facilitates the secure attachment of engine components to the truck’s frame, providing a stable and aligned platform. This alignment is essential for the efficient operation of the engine, allowing for optimal performance of interconnected parts. The mounting plate also helps distribute the weight and stresses exerted by the engine, maintaining structural integrity under various operating conditions 1.

Key Features

The 3164002 is constructed from high-strength materials, ensuring durability and resistance to the rigors of heavy-duty truck use. Its design incorporates precise machining and robust mounting points, enhancing its ability to securely hold components in place. Additionally, the plate features corrosion-resistant coatings, protecting it from environmental factors that could lead to degradation over time 2.

Benefits

Utilizing the 3164002 offers several advantages. It provides improved stability for attached components, which can lead to enhanced engine performance. The design of the plate also contributes to ease of installation, reducing the time and effort required during maintenance or upgrades. Furthermore, its durable construction ensures long-term reliability, minimizing the need for frequent replacements and contributing to overall truck maintenance efficiency 3.

Installation Process

Proper installation of the Mounting Plate involves several steps. First, the surface where the plate will be mounted should be cleaned and prepared to ensure a secure fit. The plate should then be aligned with the designated mounting points on the truck’s frame. Using the appropriate fasteners, the plate is secured in place, taking care to apply even pressure to avoid warping. It is important to follow manufacturer guidelines for torque specifications to ensure the fasteners are tightened to the correct level without over-tightening, which could damage the plate or the frame.

Troubleshooting and Maintenance

Common issues with the 3164002 may include loosening of fasteners or corrosion at the mounting points. Regular inspection during routine maintenance can help identify these issues early. If fasteners are found to be loose, they should be re-tightened to the manufacturer’s specifications. In cases of corrosion, cleaning the affected areas and applying a corrosion-resistant coating can help prolong the lifespan of the component. Regular maintenance not only ensures the continued optimal performance of the mounting plate but also contributes to the overall reliability of the truck.

Manufacturer Overview - Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established itself as a trusted name in the heavy-duty truck industry. The company’s commitment to innovation, quality, and customer satisfaction has earned it a strong reputation among professionals. Cummins’ expertise in engine manufacturing and its dedication to producing high-quality components make it a preferred choice for those in the heavy-duty truck sector.

Role of Part 3164002 Mounting Plate in Engine Systems

The 3164002 is an integral component in the assembly and operation of various engine systems. It serves as a stable foundation for the secure attachment of multiple engine components, ensuring their proper alignment and functionality.

When integrated with an Injector Leak Test Kit, the Mounting Plate provides a fixed point for the kit’s components to be mounted. This stability is essential for accurate leak testing of fuel injectors. The plate ensures that the injectors are held in a consistent position, allowing for precise measurement and detection of any leaks. This is particularly important in maintaining the integrity of the fuel system, as even minor leaks can lead to significant performance issues and fuel wastage.

In addition to its role in leak testing, the Mounting Plate also facilitates the organization and accessibility of various engine components. By providing a designated area for components to be mounted, it reduces the likelihood of misplacement or damage during maintenance procedures. This organization is beneficial for both routine checks and more complex engine diagnostics, as it allows mechanics to quickly locate and assess the condition of each part.

Furthermore, the Mounting Plate contributes to the overall structural integrity of the engine system. It helps distribute the weight and stress of attached components more evenly, which can prevent undue strain on other parts of the engine. This even distribution is particularly important in high-performance engines, where components are subjected to greater forces and temperatures.

Conclusion

In summary, the 3164002 plays a significant role in the efficient and effective operation of engine systems. Its ability to provide a stable, organized, and stress-distributing platform for various components underscores its importance in both maintenance and performance contexts.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.