This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Piston Cooling Nozzle, part number 4914952, manufactured by Cummins, is a critical component designed to enhance the performance and durability of heavy-duty truck engines. Cummins, a renowned name in the automotive and heavy-duty truck industry, produces a range of parts and systems that contribute to the efficiency and reliability of engines. The 4914952 Piston Cooling Nozzle is one such component, playing a significant role in maintaining optimal engine conditions.

Basic Concepts of Piston Cooling Nozzles

Piston cooling nozzles are integral components in the cooling systems of internal combustion engines. Their primary function is to direct a stream of coolant onto the underside of the piston, which helps in dissipating heat generated during the combustion process 1. This cooling mechanism is vital for maintaining the structural integrity of the piston and ensuring efficient engine operation. By managing the temperature within the engine, piston cooling nozzles contribute to overall engine performance and longevity.

Purpose of the 4914952 Piston Cooling Nozzle

The 4914952 Piston Cooling Nozzle is specifically designed to enhance the cooling efficiency of truck engines. It plays a role in the engine cooling system by directing a precise stream of coolant to the critical areas of the piston. This targeted cooling helps in reducing thermal stress on the piston, which in turn contributes to improved engine efficiency and durability 2. The nozzle’s design ensures that the coolant is distributed effectively, optimizing the cooling process and supporting consistent engine performance.

Key Features

The 4914952 Piston Cooling Nozzle incorporates several key features that enhance its performance. These include a robust design that ensures durability under high-stress conditions, the use of high-quality materials that resist corrosion and wear, and technological advancements such as precision engineering for accurate coolant distribution. These features collectively contribute to the nozzle’s effectiveness in maintaining optimal engine temperatures.

Benefits

Using the 4914952 Piston Cooling Nozzle offers several benefits. It provides improved engine cooling, which helps in maintaining optimal operating temperatures and reducing the risk of overheating. This enhanced cooling capability contributes to increased engine reliability and can lead to potential cost savings over time by reducing the need for frequent repairs and maintenance 3. Additionally, the efficient cooling provided by the nozzle supports better overall engine performance.

Installation and Integration

Proper installation and integration of the 4914952 Piston Cooling Nozzle are crucial for ensuring optimal performance. Guidelines for installation include ensuring that the nozzle is correctly aligned with the piston and securely fastened to prevent leaks. It is also important to verify that the coolant system is free of contaminants and that the nozzle is compatible with the specific engine model. Following these guidelines helps in achieving the best possible results from the cooling system.

Troubleshooting and Maintenance

Common issues that may arise with the 4914952 Piston Cooling Nozzle include clogging due to coolant contaminants, leaks, or misalignment. Troubleshooting these issues involves inspecting the nozzle for blockages, checking for proper alignment, and ensuring that the coolant system is clean and free of debris. Regular maintenance practices, such as flushing the coolant system and inspecting the nozzle for wear, can help in ensuring the longevity and efficient operation of the cooling system.

Performance Impact

The 4914952 Piston Cooling Nozzle has a noticeable impact on engine performance. By effectively managing engine temperatures, it contributes to improved fuel efficiency, as cooler operating temperatures allow for more efficient combustion 4. Additionally, the nozzle supports higher power output by maintaining optimal engine conditions and aids in thermal management, which is crucial for the longevity of engine components.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the automotive and heavy-duty truck industry, known for its high-quality engines and components. With a history of innovation and a diverse product range, Cummins has established a strong reputation for reliability and performance. The company’s commitment to excellence is reflected in its parts, including the 4914952 Piston Cooling Nozzle, which is designed to meet the demanding requirements of heavy-duty applications.

Compatibility with Cummins Engines

The 4914952 Piston Cooling Nozzle is designed to be compatible with several Cummins engine models. This component is integral in managing the temperature of the pistons, ensuring optimal engine performance and longevity.

For the QSNT14 engine, the Piston Cooling nozzle is engineered to fit seamlessly, providing efficient cooling and maintaining the integrity of the pistons under high-stress conditions.

Similarly, the CM876 engine benefits from the precise design of the 4914952 nozzle, which aids in dissipating heat effectively, thus preventing overheating and potential engine damage.

The N102 engine also utilizes this part, where the nozzle’s role in cooling is crucial for maintaining the engine’s efficiency and reliability.

These engines, while distinct in their specifications and applications, share a common requirement for effective piston cooling, making the 4914952 nozzle a versatile and essential component across these models.

Role of the 4914952 Piston Cooling Nozzle in Engine Systems

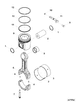

The 4914952 Piston Cooling Nozzle is an integral component in the thermal management system of an engine, specifically designed to enhance the performance and longevity of the connecting rod and piston assembly.

Integration with Connecting Rod and Piston

In high-performance engines, the connecting rod and piston endure significant thermal stress due to the combustion process. The 4914952 Piston Cooling Nozzle is strategically positioned to direct a jet of engine oil onto the underside of the piston. This oil jet effectively dissipates heat, reducing the thermal load on the piston and, by extension, the connecting rod. The consistent cooling provided by this nozzle helps maintain the structural integrity and operational efficiency of these components under high-stress conditions.

Interaction with Injector

The injector plays a pivotal role in the combustion process by delivering fuel into the combustion chamber. Efficient combustion is essential for optimal engine performance, and it generates a substantial amount of heat. The 4914952 Piston Cooling Nozzle works in tandem with the injector by managing the thermal environment within the engine. By cooling the piston, the nozzle indirectly supports the injector’s function, ensuring that the combustion process remains stable and efficient.

Contribution to Overall Performance

In the realm of performance parts, the 4914952 Piston Cooling Nozzle stands out for its ability to enhance engine durability and performance. By effectively managing heat, this component allows the engine to operate at higher efficiencies and under more demanding conditions. The reduction in thermal stress on the piston and connecting rod translates to improved engine reliability and performance, making this nozzle a valuable addition to any high-performance engine system.

Conclusion

The 4914952 Piston Cooling Nozzle by Cummins is a vital component in the thermal management of heavy-duty truck engines. Its design and features contribute to improved engine cooling, durability, and performance. Proper installation, maintenance, and understanding of its role in the engine system are essential for maximizing its benefits.

-

Pulkrabek, W. W. (2014). Engineering Fundamentals of the Internal Combustion Engine. Pearson Education.

↩ -

Martyr, A. J. (2007). Engine Testing: Theory and Practice: Third Edition. SAE International.

↩ -

Goodnight, N., & Van Gelder, K. (2018). Automotive Braking Systems. Jones & Bartlett Learning.

↩ -

Fehan, D. R. (2013). Design of Racing and High-Performance Engines 2004-2013. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.