This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

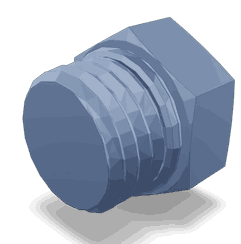

The Cummins 4093857 Pipe Plug is a component designed to maintain the integrity of fluid systems in commercial trucks. Its role is significant in ensuring that these systems operate efficiently and without leaks, which is vital for the overall performance and reliability of the vehicle 1.

Basic Concepts of Pipe Plugs

A pipe plug is a device used to seal the end of a pipe or a fluid system, preventing the escape of fluids and maintaining system pressure. It operates by fitting securely into the pipe’s end, creating a barrier that stops fluid flow and prevents contaminants from entering the system. This function is essential for maintaining the efficiency and safety of fluid systems in vehicles 2.

Purpose of the Cummins 4093857 Pipe Plug

The Cummins 4093857 Pipe Plug is specifically designed to serve in various fluid systems within trucks, including fuel, coolant, and hydraulic systems. Its application helps in sealing off sections of these systems when maintenance or modifications are performed, ensuring that the systems remain pressurized and free from leaks 3.

Key Features

This Cummins part is constructed from materials that offer durability and resistance to corrosion, ensuring long-term performance in demanding environments. Its design includes features that enhance its sealing capability, such as a tapered or threaded end that fits securely into the pipe. These characteristics contribute to its effectiveness in preventing fluid leaks and maintaining system integrity.

Benefits

Using the Cummins 4093857 Pipe Plug offers several advantages, including improved system reliability due to its secure fit and sealing capabilities. It is designed for ease of installation, which reduces downtime during maintenance procedures. Additionally, its durable construction ensures long-term use, contributing to the overall efficiency and reliability of the truck’s fluid systems.

Installation Process

Installing the Cummins 4093857 Pipe Plug involves ensuring the pipe end is clean and free from debris, then threading or tapping the plug into place. Tools such as wrenches may be required to achieve a secure fit. It is important to follow manufacturer guidelines to ensure the plug is installed correctly, providing a reliable seal.

Troubleshooting Common Issues

Common issues with pipe plugs include leaks and corrosion. To address leaks, ensure the plug is correctly installed and the pipe end is clean. Corrosion can be mitigated by using plugs made from corrosion-resistant materials and regularly inspecting the plug for signs of wear or damage.

Maintenance Tips

To prolong the lifespan of the Cummins 4093857 Pipe Plug, regular inspections should be conducted to check for signs of wear, corrosion, or damage. Cleaning the plug and the pipe end before reinstallation can prevent leaks and ensure a secure fit. Replacing the plug when signs of wear are evident will help maintain system integrity.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a broad product range and a reputation for quality and reliability, Cummins components are widely used in the automotive and commercial vehicle industries, including in the fluid systems of commercial trucks.

Compatibility

The Cummins Pipe Plug part number 4093857 is designed to fit a range of Cummins engines, ensuring compatibility and performance across various models. Here is a detailed breakdown of the engines with which this part is compatible:

4B3.9 and 6B5.9 Engines

The 4B3.9 and 6B5.9 engines are part of the earlier Cummins lineup, known for their robust construction and reliability. The Pipe Plug 4093857 fits seamlessly into these engines, providing a secure seal and maintaining the integrity of the exhaust system.

B5.6 CM2670 B152B, B5.9 GAS PLUS CM556, B6.7 CM2670 B153B

These engines, including the B5.6 CM2670 B152B, B5.9 GAS PLUS CM556, and B6.7 CM2670 B153B, benefit from the Pipe Plug 4093857. This part is engineered to match the specific design requirements of these engines, ensuring optimal performance and longevity.

ISB5.9 CM2880 Series

The ISB5.9 CM2880 series engines, which include the B110, B140, and B149 variants, are designed for heavy-duty applications. The Pipe Plug 4093857 is compatible with these engines, providing a reliable seal that helps maintain the efficiency of the exhaust system.

ISB5.9G CM2180

The ISB5.9G CM2180 engine is another model that can utilize the Pipe Plug 4093857. This part is specifically designed to fit the unique design of this engine, ensuring that it performs optimally under various operating conditions.

QSB5.9 CM2880 B115 and QSB5.9G

The QSB5.9 CM2880 B115 and QSB5.9G engines are part of Cummins’ versatile lineup. The Pipe Plug 4093857 is engineered to fit these engines, providing a secure and reliable seal that helps maintain the efficiency and performance of the exhaust system.

By ensuring compatibility with these engines, the Cummins Pipe Plug 4093857 helps maintain the integrity of the exhaust system, contributing to the overall performance and longevity of the engine.

Component Usage

The 4093857 Pipe Plug is an essential component in various engine systems, ensuring the integrity and efficiency of the engine’s operation. Its role is multifaceted, contributing to the overall performance and reliability of the engine.

Engine Oil System

In the engine oil system, the Pipe Plug is utilized to seal off unused passages or ports within the engine block and cylinder head. This ensures that engine oil flows correctly through the designated channels, preventing leaks and maintaining optimal lubrication for moving parts. It is particularly important in the Engine Oil Cooler, where it helps maintain the correct oil temperature by sealing off any unnecessary pathways.

Fuel System

Within the fuel system, the Pipe Plug is employed to block off ports in the Fuel Pump and Fuel Pump Coupling. This ensures that fuel is directed efficiently through the system, preventing any potential leaks that could compromise engine performance or pose a safety risk. Additionally, in the Air Fuel Control Plumbing, the Pipe Plug helps maintain the precise air-fuel ratio by sealing off any extraneous passages.

Exhaust System

In the Exhaust Manifold, the Pipe Plug is used to seal off any unused ports, ensuring that exhaust gases are directed efficiently out of the engine. This not only improves engine performance but also reduces emissions by preventing any escape of exhaust gases through unintended routes.

Cooling System

The Pipe Plug plays a significant role in the cooling system by sealing off ports in the Cylinder Head and Cylinder Block. This ensures that coolant flows correctly through the Engine Coolant passages, maintaining the engine’s operating temperature and preventing overheating.

Lubrication System

In the Lubricating Oil Filter Head, the Pipe Plug is used to block off any unnecessary passages, ensuring that oil is filtered efficiently before being circulated back into the engine. This contributes to the longevity of engine components by maintaining clean and effective lubrication.

Engine Control Module

The Pipe Plug is also utilized in the Engine Control Module (ECM) arrangement to seal off any unused sensor or actuator ports. This ensures that the ECM receives accurate data from the engine’s various systems, allowing for precise control and optimization of engine performance.

Turbocharger System

In turbocharger applications, the Pipe Plug is used to seal off any unused ports in the Turbocharger and Exhaust Manifold. This ensures that boost pressure is maintained efficiently, contributing to improved engine performance and responsiveness.

Conclusion

The Cummins 4093857 Pipe Plug, through its various applications across different engine systems, plays a significant role in ensuring the engine’s efficiency, reliability, and safety. Its ability to seal off unused passages and ports contributes to the optimal functioning of the engine’s oil, fuel, exhaust, cooling, lubrication, and control systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.