This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

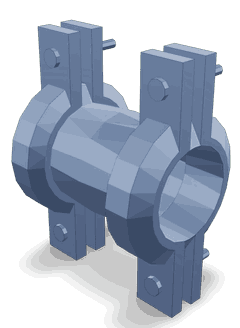

The Cummins 3872284 Pipe Connector is a component designed for use in commercial trucks, contributing to the overall operation and efficiency of the vehicle. Manufactured by Cummins Inc., this part is part of a broader range of products that enhance the performance and reliability of commercial vehicles 1.

Basic Concepts of Pipe Connectors

Pipe connectors are components used in fluid systems to join pipes and facilitate the transfer of liquids or gases. In automotive applications, they ensure the smooth operation of various systems by providing secure and leak-proof connections. These connectors are designed to withstand the pressures and temperatures associated with automotive fluid systems, ensuring reliable performance over time 2.

Purpose of the 3872284 Pipe Connector

The 3872284 Pipe Connector is designed to provide a secure connection between pipes, allowing for the efficient transfer of fluids. This connector is integral to maintaining the integrity of the fluid system, ensuring that fluids are delivered to their intended destinations without leaks or interruptions 3.

Key Features

The 3872284 Pipe Connector features a design that includes durable materials and precise engineering to enhance its performance and longevity. Its material composition is chosen to resist corrosion and wear, ensuring it can withstand the harsh conditions often encountered in commercial truck operations. The design attributes of this connector, such as its threading and sealing mechanisms, are tailored to provide a secure fit and prevent leaks 4.

Benefits

The use of the 3872284 Pipe Connector offers several advantages. It contributes to improved efficiency within the truck’s fluid systems by ensuring secure and leak-proof connections. This reliability can lead to cost savings for fleet operators by reducing the need for frequent repairs and maintenance. Additionally, the durability of this connector means it can withstand the rigors of commercial use, providing long-term value 5.

Installation Process

Installing the 3872284 Pipe Connector requires following a step-by-step process to ensure a secure fit. This involves preparing the connection points, applying any necessary sealants, and using the appropriate tools to tighten the connector. Best practices include checking for proper alignment and ensuring that all connections are tight to prevent leaks. Detailed instructions and any required tools should be referenced for a successful installation 6.

Maintenance Tips

Regular maintenance of the 3872284 Pipe Connector is recommended to ensure its longevity and optimal performance. This includes periodic inspections for signs of wear or damage, cleaning the connector and surrounding areas to prevent buildup, and tightening connections as needed. Adhering to these maintenance practices can help prevent issues and ensure the connector continues to function effectively 7.

Troubleshooting Common Issues

Common problems associated with pipe connectors, such as leaks or corrosion, can often be addressed through troubleshooting. Identifying the source of a leak may involve checking the connections for tightness and inspecting the connector for signs of damage. Corrosion can be mitigated by ensuring the connector is made from materials resistant to the fluids it contacts and by applying protective coatings where appropriate 8.

Safety Considerations

When working with the 3872284 Pipe Connector, it is important to observe safety guidelines and precautions. This includes wearing appropriate personal protective equipment, ensuring the truck’s engine is off and cool before beginning work, and following handling procedures to avoid injury. Being aware of potential hazards, such as fluid leaks or sharp edges, can help ensure a safe working environment 9.

Environmental Impact

The design and materials used in the 3872284 Pipe Connector are considered with environmental impact in mind. Efforts are made to use eco-friendly materials where possible and to design the connector in a way that minimizes waste and maximizes durability. This approach helps reduce the environmental footprint of the component over its lifecycle 10.

About Cummins

Cummins Inc. is a leader in the automotive industry, known for its wide range of products that power commercial vehicles around the world. With a history of innovation and a commitment to quality, Cummins has established itself as a trusted provider of components that enhance the performance and reliability of vehicles. The company’s product range includes engines, filtration systems, and aftermarket parts, all designed with the aim of meeting the demanding needs of commercial fleets 11.

Compatibility

The Cummins Pipe Connector part number 3872284 is designed to fit seamlessly with a variety of Cummins engines, ensuring efficient fluid transfer and system integrity. This part is compatible with the following engines:

- 6C8.3

- K19

- K38

- K50

- N14 G

- NH/NT 855

- QSK50 CM2150 MCRS

- QST30 CM552

For the engines K19, K38, and K50, the pipe connector 3872284 is engineered to integrate smoothly, providing a reliable connection for fluid lines. This ensures that the engines maintain optimal performance and longevity.

Similarly, the N14 G engine benefits from this connector, which is crucial for maintaining the integrity of the engine’s cooling and fuel systems. The connector’s design ensures a secure fit, minimizing the risk of leaks and other fluid-related issues.

The NH/NT 855 engine also relies on the 3872284 pipe connector for its fluid management systems. This part is critical in ensuring that the engine operates efficiently and reliably.

For the QSK50 CM2150 MCRS and QST30 CM552 engines, the pipe connector 3872284 is essential for maintaining the fluid pathways that are integral to the engine’s operation. Its precision fit and robust construction make it a vital component in these high-performance engines.

Role of the 3872284 Pipe Connector in Engine Systems

The 3872284 Pipe Connector is integral to the seamless operation of various engine systems by facilitating the secure and efficient transfer of fluids. This component is designed to interface with multiple systems, ensuring that each operates within optimal parameters.

Integration with Cooling Systems

In cooling systems, the Pipe Connector is utilized in the radiator plumbing and aftercooler water plumbing. It ensures a reliable connection between the radiator and the water pump kit, allowing coolant to circulate effectively. Additionally, it plays a role in the aftercooler by connecting the aftercooler water plumbing to the coolant piping, which is essential for maintaining the temperature of the compressed air in turbocharged engines.

Heat Exchanger Applications

The Pipe Connector is also vital in heat exchanger applications. It is used in the connection heat exchanger and heat exchanger connection, linking the cooler to the engine oil system. This ensures that the heat exchanger can effectively dissipate heat from the engine oil, contributing to the overall efficiency and longevity of the engine.

Intercooler and Plumbing Systems

In intercooler systems, the Pipe Connector is employed in the intercooler assembly and intercooler plumbing. It connects the intercooler to the engine installation kit, allowing for the efficient cooling of intake air, which is crucial for performance and reliability.

Auxiliary and Vent Systems

For auxiliary cooling and vent systems, the Pipe Connector is part of the auxiliary cooling setup and the vent system kit. It ensures that these systems can operate effectively, helping to manage temperatures and pressures within the engine compartment.

Specialized Connections

The Pipe Connector is also used in specialized connections such as the mounting connection aftercooler and the exchanger heat mounting. These connections are critical for securing components in place and ensuring that they function as intended within the engine system.

Comprehensive System Integration

Overall, the 3872284 Pipe Connector is a versatile component that enhances the functionality of various engine systems. Whether it’s part of the radiator parts, plumbing aftercooler, or engine installation kit, its role in maintaining fluid dynamics and system integrity is indispensable.

Conclusion

The Cummins 3872284 Pipe Connector is a critical component in the fluid systems of commercial trucks, ensuring efficient and reliable operation. Its design, compatibility with various Cummins engines, and role in multiple engine systems highlight its importance in maintaining vehicle performance and reliability.

-

Sclar, Deanna. Auto Repair for Dummies: 2nd Edition. For Dummies, 2008.

↩ -

Singh, D. K. Dictionary of Mechanical Engineering. Springer Nature, 2024.

↩ -

Kasab, John, and Andrea Strzelec. Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International, 2020.

↩ -

Norman, Andrew. Diesel Technology Fundamentals Service Repair Eighth Edition. The Goodheart-Willcox Company Inc, 2016.

↩ -

Sclar, Deanna. Auto Repair for Dummies: 2nd Edition. For Dummies, 2008.

↩ -

Singh, D. K. Dictionary of Mechanical Engineering. Springer Nature, 2024.

↩ -

Kasab, John, and Andrea Strzelec. Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International, 2020.

↩ -

Norman, Andrew. Diesel Technology Fundamentals Service Repair Eighth Edition. The Goodheart-Willcox Company Inc, 2016.

↩ -

Sclar, Deanna. Auto Repair for Dummies: 2nd Edition. For Dummies, 2008.

↩ -

Kasab, John, and Andrea Strzelec. Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International, 2020.

↩ -

Norman, Andrew. Diesel Technology Fundamentals Service Repair Eighth Edition. The Goodheart-Willcox Company Inc, 2016.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.