This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

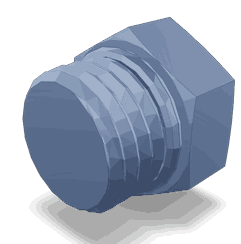

The Cummins 3863363 Pipe Plug is a component designed to ensure the integrity of fluid systems in commercial trucks. Its role is to prevent fluid leakage, thereby maintaining system efficiency and reliability. Understanding its function and significance is important for maintaining the operational standards of commercial vehicles.

Basic Concepts of Pipe Plugs

A pipe plug is a device used in fluid systems to seal openings and prevent the escape of fluids. It operates by fitting securely into a pipe or fitting, creating a barrier that stops fluid from leaking out. This is achieved through a tight seal, often enhanced by threading or other sealing mechanisms 1.

Purpose of the Cummins 3863363 Pipe Plug

The Cummins 3863363 Pipe Plug serves a specific function in the operation of trucks by sealing various fluid systems. It is applied in systems where fluid containment is necessary to maintain operational efficiency and prevent contamination. This includes applications in fuel, coolant, and hydraulic systems, where the integrity of the fluid path is crucial for system performance 2.

Key Features

The Cummins 3863363 Pipe Plug is characterized by several key features that enhance its performance. It is typically made from durable materials that resist corrosion and wear, ensuring long-term reliability. The design may include threading for a secure fit, and it could have a gasket or O-ring to improve the seal. These features contribute to its effectiveness in preventing fluid leakage 3.

Benefits

Using the Cummins 3863363 Pipe Plug offers several benefits. It contributes to improved system reliability by ensuring that fluid systems remain sealed and operational. The design of the plug facilitates ease of installation, reducing downtime during maintenance. Additionally, its durable construction ensures long-term performance, minimizing the need for frequent replacements.

Installation Process

Installing the Cummins 3863363 Pipe Plug involves several steps to ensure a secure fit. First, the fitting area should be cleaned to remove any debris or old sealant. The plug is then screwed into place, ensuring it is tightened to the manufacturer’s specifications to achieve a proper seal. Tools such as a torque wrench may be used to ensure the correct tightening force is applied.

Maintenance Tips

To maintain the Cummins 3863363 Pipe Plug, regular inspections are recommended. Look for signs of wear, corrosion, or damage that could compromise the seal. If the plug shows signs of deterioration or if a leak is detected, it should be replaced to prevent system failure. Keeping the area around the plug clean and free of debris can also extend its lifespan.

Troubleshooting Common Issues

Common issues with pipe plugs include leaks and corrosion. If a leak is detected, inspect the plug for proper seating and ensure there is no damage to the sealing surfaces. Corrosion can be addressed by cleaning the affected areas and applying a compatible sealant or replacing the plug if necessary. Regular maintenance can help identify and resolve these issues before they lead to system failure.

Compatibility and Applications

The Cummins 3863363 Pipe Plug is designed for use in various fluid systems within commercial trucks. Its applications include, but are not limited to, fuel, coolant, and hydraulic systems. Ensuring compatibility with the specific system and following manufacturer guidelines for use is important for optimal performance and reliability.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history spanning over a century, Cummins is renowned for its engines, filtration, and power generation products. The company’s commitment to innovation and quality has established it as a trusted name in the commercial truck industry, providing reliable components that contribute to the efficiency and durability of vehicles.

Role of Part 3863363 Pipe Plug in Engine Systems

The Cummins 3863363 Pipe Plug is an essential component in various engine systems, ensuring optimal performance and efficiency. It is strategically utilized in several key areas:

Turbocharger Arrangement

In turbocharger setups, the Pipe Plug is employed to seal off unused ports or passages. This helps maintain the integrity of the turbocharger’s air flow, ensuring that the system operates efficiently without leaks. It also aids in balancing the pressure within the turbocharger, contributing to consistent performance.

Camshaft and Cylinder Head

When integrated into the camshaft and cylinder head assemblies, the Pipe Plug serves to block off unnecessary channels. This is particularly important in engines with variable valve timing systems, where precise control over air and fuel mixture is vital. The Plug ensures that only the required pathways are open, enhancing the engine’s overall performance.

Exhaust Manifold and Head

In the exhaust manifold and cylinder head, the Pipe Plug is used to seal off coolant passages that are not in use. This prevents coolant leakage and maintains the thermal efficiency of the engine. Proper sealing is essential for consistent engine temperature, which directly impacts combustion efficiency and emissions.

Injector and Manifold

Within the fuel injector and intake manifold systems, the Pipe Plug is utilized to close off fuel lines or air passages that are not required during specific operating conditions. This helps in fine-tuning the air-fuel ratio, leading to improved fuel economy and reduced emissions.

Exhaust Recirculation Air

In systems involving exhaust gas recirculation (EGR), the Pipe Plug is used to manage the flow of recirculated exhaust gases. By sealing off certain pathways, it ensures that the EGR system operates within designed parameters, reducing nitrogen oxides (NOx) emissions and enhancing overall engine performance.

Turbocharger Location

At the turbocharger location, the Pipe Plug is often used to seal off boost pressure lines that are not in use. This maintains the desired boost levels and prevents any unwanted pressure drops, ensuring that the turbocharger delivers consistent performance across varying engine speeds.

Plumbing and Parts Performance

In the broader context of engine plumbing, the Pipe Plug is a versatile component that enhances the performance of various parts. By sealing off unnecessary passages, it contributes to the efficient operation of the engine, ensuring that all systems work in harmony to deliver optimal performance.

Conclusion

The Cummins 3863363 Pipe Plug plays a crucial role in maintaining the integrity and efficiency of fluid systems in commercial trucks. Its design and features ensure reliable sealing, contributing to the overall performance and reliability of the vehicle. Regular maintenance and proper installation are key to maximizing the benefits of this component.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.