This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

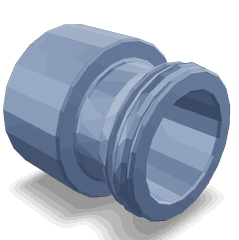

The Cummins 3682542 Plain Pipe Coupling is a component designed for use in commercial truck operations. Its purpose is to facilitate the secure connection of pipes within fluid transfer systems. This coupling plays a role in the efficient and reliable operation of various truck systems by maintaining the integrity of fluid pathways.

Basic Concepts of Plain Pipe Couplings

Plain pipe couplings are mechanical devices used to join two sections of pipe together. They function by aligning the pipes and securing them in place, allowing for the continuous flow of fluids such as fuel, coolant, or hydraulic fluid. These couplings are commonly employed in systems where flexibility and ease of assembly are required. They are typically used in applications where the pipes may need to be disconnected for maintenance or repair 1.

Purpose of the Cummins 3682542 Plain Pipe Coupling

The Cummins 3682542 Plain Pipe Coupling serves to connect pipes in a truck’s fluid transfer systems. It ensures a leak-free connection, which is vital for the proper functioning of the truck. By facilitating the transfer of fluids, this coupling helps maintain the operational efficiency of the truck’s systems, such as the fuel delivery or hydraulic systems.

Key Features

The Cummins 3682542 Plain Pipe Coupling is characterized by several key features that enhance its performance. It is constructed from durable materials that can withstand the pressures and temperatures encountered in truck fluid systems. The design includes elements that ensure a tight seal between connected pipes, minimizing the risk of leaks. Additionally, it may feature unique characteristics such as corrosion resistance or ease of installation, which contribute to its reliability and functionality 2.

Benefits

The Cummins 3682542 Plain Pipe Coupling offers several advantages. Its durable construction ensures long-term reliability, even under demanding conditions. The ease of installation reduces downtime during maintenance procedures. Furthermore, its reliable performance contributes to the overall efficiency of the truck’s fluid systems, enhancing operational effectiveness.

Common Applications

In commercial trucks, the Cummins 3682542 Plain Pipe Coupling is typically used in various fluid transfer systems. These may include fuel lines, coolant systems, and hydraulic circuits. Its versatility makes it suitable for a wide range of applications where secure and flexible pipe connections are required.

Installation Process

Installing the Cummins 3682542 Plain Pipe Coupling involves several steps. First, ensure that the pipes to be connected are clean and free of debris. Align the pipes and insert them into the coupling until they are fully seated. Use the appropriate tools to secure the coupling, ensuring a tight and leak-free connection. It may be necessary to use additional components, such as gaskets or seals, to enhance the connection’s integrity.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 3682542 Plain Pipe Coupling, regular maintenance is recommended. This includes periodic inspections to check for signs of wear or damage. Cleaning the coupling and its surrounding areas can prevent the buildup of contaminants that may affect its performance. Additionally, ensuring that the coupling remains properly secured can help maintain a leak-free connection.

Troubleshooting Common Issues

Frequent problems with plain pipe couplings may include leaks, difficulty in installation, or corrosion. To address these issues, inspect the coupling for any signs of damage or wear. Ensure that the pipes are properly aligned and seated within the coupling. Applying a compatible sealant can help prevent leaks. In cases of corrosion, replacing the coupling may be necessary to restore system integrity 3.

Safety Considerations

When installing, maintaining, or troubleshooting the Cummins 3682542 Plain Pipe Coupling, it is important to observe safety guidelines. This includes wearing appropriate personal protective equipment, such as gloves and safety glasses. Ensure that the truck’s systems are depressurized before beginning any work to prevent injury from fluid spray. Follow all manufacturer recommendations for installation and maintenance procedures to ensure safe and effective use of the coupling.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company offers a wide range of products designed to meet the demanding requirements of commercial vehicle operators, ensuring reliable and efficient performance 4.

Cummins Plain Pipe Coupling 3682542 in Engine Applications

The Cummins Plain Pipe Coupling 3682542 is a component in the assembly of various engine systems, ensuring seamless connections between pipes and hoses. This coupling is designed to provide a reliable and durable connection, crucial for maintaining the integrity of the engine’s exhaust and fluid systems.

ISX CM870 Engine

In the ISX CM870 engine, the Plain Pipe Coupling 3682542 is integral to the engine’s exhaust system. It connects various sections of the exhaust piping, ensuring that the exhaust gases flow efficiently from the turbocharger to the muffler. This coupling’s robust design helps to withstand the high temperatures and pressures typical in diesel engines, ensuring longevity and performance.

Grouping of Engines

The Plain Pipe Coupling 3682542 is not limited to the ISX CM870 engine alone. It is also used in other Cummins engines within the same family or similar applications. These engines often share design philosophies and component compatibility, making the 3682542 a versatile part across multiple engine models. This commonality allows for easier maintenance and repair, as technicians can use the same part across different engine types, reducing inventory needs and simplifying the repair process.

Importance in Engine Systems

The coupling’s role in the engine’s overall system is vital. It ensures that connections between pipes and hoses are secure and leak-free, which is essential for the engine’s operational efficiency and safety. The durability and precision of the 3682542 coupling help in maintaining the performance standards expected from Cummins engines, contributing to their reputation for reliability and efficiency.

Role of Part 3682542 Plain Pipe Coupling in Engine Systems

In the context of engine systems, the part 3682542 Plain Pipe Coupling is instrumental in ensuring the seamless operation of various components.

Integration with Recirculation Systems

When incorporated into recirculation systems, the Plain Pipe Coupling facilitates the smooth transfer of fluids or gases between different sections of the system. This is particularly important in systems where recirculation of exhaust gases is employed to reduce emissions and improve fuel efficiency. The coupling ensures that the recirculated gases are effectively channeled back into the intake system without any significant loss of pressure or efficiency.

Functionality in Exhaust Systems

In exhaust systems, the Plain Pipe Coupling plays a role in connecting various exhaust components such as the exhaust manifold, catalytic converter, and muffler. By providing a secure and leak-proof connection, it helps maintain the integrity of the exhaust flow. This is essential for optimal engine performance and compliance with emission standards. The coupling also aids in absorbing vibrations and reducing noise, contributing to a more efficient and quieter exhaust system.

Conclusion

Overall, the Plain Pipe Coupling is a fundamental component that enhances the reliability and efficiency of both recirculation and exhaust systems in engine operations. Its robust design, ease of installation, and maintenance benefits make it a critical part in ensuring the seamless and efficient operation of commercial truck engines.

-

Wilfried J Bartz, Engine Oils and Automotive Lubrication Mechanical Engineering Book 80, CRC Press, 2019.

↩ -

Alan Robinson and Andrew Livesey, The Repair of Vehicle Bodies Fifth Edition, Elsevier, 2006.

↩ -

Karsten Berns et al., Proceedings of the 5th Commercial Vehicle Technology Symposium CVT, Springer, 2018.

↩ -

Tigran Parikyan Ed, Advances in Engine and Powertrain Research and Technology, Springer Nature, 2022.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.