This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

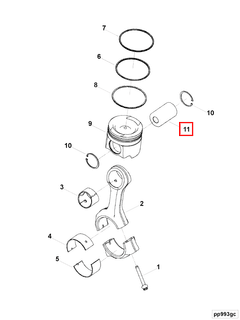

The 4975036 Piston Pin, manufactured by Cummins, is a component designed for use in heavy-duty truck engines. Cummins, a well-established name in the engine manufacturing industry, produces a range of parts that are integral to the performance and reliability of heavy-duty engines. This part is significant in this context as it plays a role in the efficient operation of truck engines by facilitating the connection between the piston and the connecting rod 4.

Basic Concepts of Piston Pins

A piston pin, also known as a wrist pin, is a component found in internal combustion engines. Its primary function is to connect the piston to the small end of the connecting rod, allowing the piston to move up and down within the cylinder while the connecting rod rotates at the crankshaft. There are two main types of piston pins: floating and fixed. Floating piston pins are free to move within the piston, which can help in reducing friction and wear. Fixed piston pins, on the other hand, are secured in place and do not move relative to the piston 2.

Purpose and Function of the 4975036 Piston Pin

This part serves to connect the piston to the connecting rod in a truck engine. This connection is vital for the reciprocating motion of the piston, which is necessary for the engine’s operation. By allowing the piston to move smoothly within the cylinder while the connecting rod rotates, the piston pin contributes to the engine’s ability to convert the linear motion of the piston into rotational motion at the crankshaft 3.

Key Features of the 4975036 Piston Pin

The 4975036 is designed with specific features that enhance its performance and durability. These include precise manufacturing tolerances to ensure a snug fit within the piston and connecting rod, surface treatments to reduce friction and wear, and the use of high-quality materials that can withstand the high stresses and temperatures encountered in heavy-duty applications 4.

Benefits of Using the 4975036 Piston Pin

Utilizing this Cummins part in heavy-duty truck engines can lead to several advantages. These include improved engine efficiency due to reduced friction, decreased wear on the piston and connecting rod, and enhanced reliability under demanding operating conditions. The design and materials used in this piston pin contribute to its ability to perform well in the challenging environment of a heavy-duty engine 4.

Installation and Maintenance

Proper installation of the 4975036 is important for ensuring optimal performance and longevity. This involves correctly positioning the pin within the piston and connecting rod, and securing it in place according to manufacturer specifications. Regular maintenance, including periodic inspection for signs of wear or damage, is recommended to ensure the piston pin continues to function effectively 1.

Troubleshooting Common Issues

Common issues associated with piston pins, such as excessive wear or failure, can often be traced back to installation errors, insufficient lubrication, or operational stresses beyond the component’s design limits. Troubleshooting these issues involves a systematic approach to identify the root cause, whether it be through inspection, analysis of operating conditions, or review of maintenance practices 2.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the heavy-duty truck and engine industry. The company’s product range includes engines for on-highway and off-highway applications, as well as components and systems that enhance engine performance and efficiency 4.

Cummins Piston Pin 4975036 Compatibility

The Cummins piston pin part number 4975036 is designed to fit a variety of Cummins engines, ensuring reliable performance and durability across different engine models. Here is a detailed look at the compatibility of this part with specific Cummins engines:

ISX12/ISX11.9 CM2250

The ISX12 and ISX11.9 CM2250 engines are part of Cummins’ heavy-duty lineup, known for their robust performance and efficiency. The piston pin 4975036 is engineered to fit these engines, providing the necessary stability and precision required for their high-power output.

ISZ13 CM2150 Z105

The ISZ13 CM2150 Z105 engine is another model in Cummins’ range, designed for medium-duty applications. The piston pin 4975036 is compatible with this engine, ensuring smooth operation and longevity.

QSZ13 CM2150 Z101 and QSZ13 CM2150 Z102

Both the QSZ13 CM2150 Z101 and QSZ13 CM2150 Z102 engines are part of Cummins’ medium-duty series. The piston pin 4975036 is suitable for these engines, providing the critical connection needed between the piston and the connecting rod.

Z13 Z108G

The Z13 Z108G engine is a medium-duty model that benefits from the precision and reliability of the piston pin 4975036. This part is designed to fit seamlessly into the engine, ensuring optimal performance and durability.

By ensuring compatibility with these engines, the Cummins piston pin 4975036 helps maintain the integrity and efficiency of the engine’s internal components, contributing to the overall reliability and performance of the vehicle 4.

Understanding the Role of Part 4975036 Piston Pin in Engine Systems

The part 4975036 is an essential component in the intricate dance of engine mechanics. It serves as the pivotal connection between the connecting rod and the piston, allowing for smooth and efficient transfer of force generated by the combustion process.

Interaction with the Connecting Rod and Piston

The Piston Pin facilitates the articulation of the connecting rod relative to the piston. As the piston moves up and down within the cylinder, the Piston Pin enables the connecting rod to pivot, translating the linear motion of the piston into the rotational motion of the crankshaft. This seamless interaction is fundamental to the engine’s operation, ensuring that the force generated by each combustion event is effectively harnessed to drive the vehicle 2.

Contribution to the Engine Piston Kit

Within the engine piston kit, the Piston Pin plays a supporting yet significant role. It is designed to withstand the high stresses and temperatures encountered within the engine, ensuring durability and reliability. The proper functioning of the Piston Pin is essential for the overall performance and longevity of the piston kit 4.

Relationship with the Cylinder and Cylinder Head

As the piston moves within the cylinder, the Piston Pin must maintain precise alignment to prevent excessive wear or damage to the cylinder walls. Additionally, the Piston Pin’s role extends to the interaction between the piston and the cylinder head. Proper alignment and movement of the piston, facilitated by the Piston Pin, are vital for maintaining the seal between the piston rings and the cylinder walls, which is crucial for compression and efficiency 3.

Impact on Injector Performance

The timing and precision of the piston’s movement, influenced by the Piston Pin, also affect the performance of the injector. Accurate piston positioning ensures that the injector delivers fuel at the optimal moment, contributing to efficient combustion and overall engine performance 2.

Influence on Camshaft Operation

Although indirectly, the Piston Pin’s role in ensuring smooth piston movement impacts the camshaft’s operation. The camshaft controls the opening and closing of the valves, which must be synchronized with the piston’s movement for efficient engine operation. Any irregularities in piston movement, potentially caused by issues with the Piston Pin, could disrupt this synchronization, affecting engine performance 3.

Conclusion

The reliability and performance of various engine parts are interconnected, and the Piston Pin is a key player in this network. Its role in facilitating the smooth operation of the connecting rod and piston directly influences the efficiency and performance of the entire engine system. Ensuring the Piston Pin is in optimal condition is therefore essential for maintaining the performance and reliability of the engine 4.

-

Cummins Inc. (n.d.). ISB5.9 CM2880 B149 Service Manual (5467237).

↩ -

Han, Z. (2022). Simulation and Optimization of Internal Combustion Engines. SAE International.

↩ ↩ ↩ ↩ -

Williams, D. (2022). Generalized Vehicle Dynamics. SAE International.

↩ ↩ ↩ -

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ ↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.