Minimum Quantity 10

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

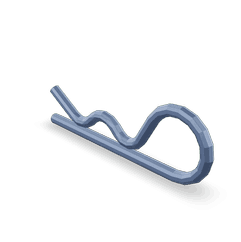

The 3919449 Cotter Pin, manufactured by Cummins, is a specialized fastener designed for use in commercial trucks. Cummins, a well-established name in the automotive industry, produces this cotter pin to meet the rigorous demands of heavy-duty applications. This component is integral to the secure operation of various truck systems, ensuring that connections remain intact under significant stress and vibration.

Basic Concepts of Cotter Pins

A cotter pin is a simple yet effective fastener used in mechanical systems to secure components that are subject to vibration or rotation. It consists of a metal pin with a bent end, which is inserted through a hole in the components to be joined. Once in place, the bent end prevents the pin from being removed, thereby securing the components together. Cotter pins are commonly used in applications where a non-permanent fastening method is required, allowing for easy disassembly when needed 1.

Purpose of Cotter Pin 3919449 in Truck Operation

The 3919449 plays a specific role in the operation and maintenance of commercial trucks. It is utilized in various truck systems where secure fastening is necessary to ensure safety and efficiency. This includes applications in the brake system, where it helps to keep components aligned and secure, and in the drivetrain, where it ensures that parts remain connected under operational stress. The pin’s design allows it to withstand the dynamic forces encountered in truck operations, contributing to the overall reliability of the vehicle 2.

Key Features of Cotter Pin 3919449

The design and material characteristics of the 3919449 are tailored to meet the demands of heavy-duty applications. Crafted from high-strength steel, this cotter pin offers durability and resistance to wear and corrosion. Its precise dimensions and bent end design ensure a secure fit, while the material’s flexibility allows it to accommodate minor misalignments without compromising the connection’s integrity. These features contribute to the effectiveness and longevity of the 3919449 in commercial truck environments 3.

Benefits of Using Cotter Pin 3919449

The use of the 3919449 provides several advantages in truck maintenance and operation. It enhances the security of connections, ensuring that components remain firmly in place under operational conditions. The design of the pin allows for easy installation and removal, facilitating quick maintenance procedures. Additionally, its contribution to overall system reliability helps to minimize downtime and reduce the risk of operational failures 4.

Installation and Usage Guidelines

Proper installation of the 3919449 is crucial for ensuring its effectiveness. To install, align the components to be joined and insert the pin through the designated hole. Ensure that the bent end of the pin is positioned to prevent removal. It is important to use the correct size of cotter pin for the application to ensure a secure fit. Common applications within truck maintenance include securing brake components and drivetrain parts.

Troubleshooting and Maintenance

Regular inspection of cotter pins is recommended to identify signs of wear or failure. Look for bending, corrosion, or any damage to the pin that could compromise its effectiveness. If a cotter pin shows signs of wear, it should be replaced to maintain the integrity of the connection. Proper maintenance practices, including regular inspections and timely replacements, ensure the longevity and performance of cotter pins in truck systems.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s commitment to excellence is reflected in its product range, which includes a variety of components designed to meet the demanding requirements of heavy-duty applications. Cummins’ focus on quality and innovation ensures that its products, like the 3919449, deliver reliable performance in commercial truck operations.

Cummins Engine Compatibility with Cotter Pin Part 3919449

The 3919449, a Cotter Pin, is designed to fit seamlessly within a range of Cummins engines. This part is essential for securing various components, ensuring the engine’s operational integrity and safety. Here is a detailed look at how this cotter pin fits with the specified engines:

4B3.9 and 6B5.9 Engines

The 4B3.9 and 6B5.9 engines, both part of Cummins’ lineup, share a commonality in their design that allows the 3919449 cotter pin to be used effectively. These engines are known for their robust construction and reliability, making them suitable for heavy-duty applications. The cotter pin is typically used in these engines to secure components such as valve train parts, ensuring they remain in place under high stress and vibration conditions.

6C8.3 and L8.9 Engines

The 6C8.3 and L8.9 engines, while distinct in their specifications, also benefit from the use of the 3919449 cotter pin. These engines are designed for durability and performance, often used in demanding environments. The cotter pin’s role in these engines is crucial for maintaining the alignment and stability of moving parts, which is vital for the engine’s longevity and efficiency.

Application Across Engine Models

The 3919449 cotter pin’s design ensures it is compatible with the specific requirements of each engine model. Its application across the 4B3.9, 6B5.9, 6C8.3, and L8.9 engines highlights its versatility and importance in maintaining the structural integrity of these engines. Whether securing valve train components or other critical parts, this cotter pin is engineered to perform reliably under the demanding conditions these engines operate in.

Cotter Pin Component Usage in Engine Systems

The 3919449 is instrumental in ensuring the secure assembly and operation of various engine components. In the context of fuel shutoff valve kits, the Cotter Pin plays a significant role in maintaining the integrity of the valve assembly. It secures the components together, preventing any unintended movement or separation that could lead to fuel leaks or improper valve function.

For the Chrysler 12V and 24V fuel shutoff kits, the Cotter Pin is used to lock the valve components in place, ensuring that the valve operates smoothly and reliably. This is particularly important in high-stress environments where vibrations and mechanical stresses could otherwise cause components to loosen.

In the Ford 12V and 24V fuel shutoff kits, the Cotter Pin serves a similar function, providing a secure connection between the valve components. This ensures that the fuel shutoff mechanism functions correctly, allowing for precise control over the fuel supply to the engine.

The solenoid kit also benefits from the use of the Cotter Pin. By securing the solenoid components, it ensures that the solenoid operates efficiently, providing reliable actuation of the fuel shutoff valve. This is essential for maintaining consistent engine performance and fuel delivery.

Overall, the Cotter Pin is a small yet vital component in the assembly and operation of fuel shutoff valve kits across various engine systems. Its role in securing components together cannot be overstated, as it contributes to the overall reliability and safety of the engine’s fuel management system.

Conclusion

The 3919449 Cotter Pin by Cummins is a critical component in the maintenance and operation of commercial trucks and engines. Its design, material, and application ensure secure fastening in various systems, contributing to the overall reliability and safety of the vehicle. Proper installation, regular maintenance, and timely replacement are essential practices to ensure the longevity and performance of this part in demanding environments.

-

Schuetz, T. (2016). Aerodynamics of Road Vehicles: Fifth Edition. SAE International.

↩ -

Singh, D. K. (2024). Dictionary of Mechanical Engineering. Springer Nature.

↩ -

Taghavifar, H., & Mardani, A. (2017). Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer.

↩ -

Pulkrabek, W. W. (2014). Engineering Fundamentals of the Internal Combustion Engine. Pearson Education.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.