This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

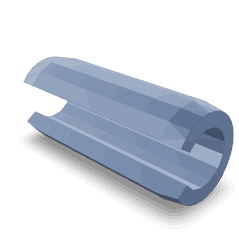

The Cummins 4989847 Roll Pin is a specialized component designed for use in commercial truck operations. Its purpose is to secure various mechanical components in place, ensuring the smooth and reliable operation of the truck. This part is integral to maintaining the structural integrity and functionality of certain truck parts, contributing to the overall efficiency and performance of commercial vehicles.

Basic Concepts of Roll Pins

Roll pins are cylindrical fasteners used in mechanical systems to hold components together. They function by being pressed into pre-drilled holes, creating a secure fit that prevents movement between parts. Roll pins are commonly used in applications where components need to be aligned precisely and held firmly in place without the use of threads or adhesives. Their design allows for easy installation and removal, making them a versatile choice for various mechanical assemblies 1.

Purpose of the Cummins 4989847 Roll Pin

The Cummins 4989847 Roll Pin plays a specific role in the operation of commercial trucks by securing components such as gears, shafts, and other mechanical parts. Its application ensures that these components remain aligned and stationary during operation, which is vital for the proper functioning of the truck’s engine and transmission systems. By maintaining the correct positioning of parts, this roll pin helps to prevent wear, misalignment, and potential failure of critical truck components 2.

Key Features

The Cummins 4989847 Roll Pin is characterized by several key features that enhance its performance and durability. It is made from high-quality materials, typically steel, which provides strength and resistance to wear. The roll pin has precise dimensions to ensure a snug fit in the designated holes, and its smooth surface finish reduces friction and the risk of galling. These design characteristics contribute to the roll pin’s reliability and longevity in demanding commercial truck applications.

Benefits

Using the Cummins 4989847 Roll Pin offers several benefits. It provides improved mechanical stability by securely holding components in place, which is crucial for the smooth operation of truck systems. The roll pin’s durable construction ensures enhanced longevity, reducing the need for frequent replacements. Additionally, its reliable performance under stress contributes to the overall efficiency and safety of commercial trucks.

Installation Process

Proper installation of the Cummins 4989847 Roll Pin is crucial for its effective function. The process involves using appropriate tools such as a press or hammer to insert the roll pin into the pre-drilled holes. It is important to ensure that the holes are clean and free of debris to achieve a secure fit. The roll pin should be driven in until it is flush with the surrounding surface, ensuring that it is properly seated and aligned with the components it is securing.

Troubleshooting Common Issues

Common issues associated with roll pins include misalignment and wear. Misalignment can occur if the roll pin is not properly seated or if the holes are not drilled accurately. Wear may result from excessive movement or inadequate material quality. To address these issues, it is important to inspect the roll pin and surrounding components regularly. If misalignment is detected, the roll pin should be re-seated or replaced. Signs of wear may indicate the need for replacement to maintain optimal performance.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 4989847 Roll Pin, regular maintenance is recommended. This includes periodic inspection of the roll pin and the components it secures to check for signs of wear or damage. Cleaning the roll pin and its surrounding areas can prevent debris buildup, which may affect its function. Following manufacturer guidelines for replacement intervals can help maintain the reliability of the truck’s mechanical systems.

Role in Truck Performance

The Cummins 4989847 Roll Pin contributes to the overall performance and reliability of commercial trucks by ensuring that critical components remain securely in place. Its role in maintaining the alignment and stability of parts within the engine and transmission systems is vital for the efficient operation of the truck. By preventing movement and wear, the roll pin helps to enhance the durability and performance of these systems, ultimately contributing to the truck’s reliability and efficiency on the road.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and related technologies. With a strong reputation in the commercial truck industry, Cummins is known for its high-quality products and innovative solutions that enhance the performance and reliability of commercial vehicles. The company’s commitment to excellence and customer satisfaction has established it as a trusted name in the industry.

Cummins Engine Roll Pin 4989847

The Cummins engine part 4989847, identified as a Roll Pin, is a critical component in the assembly of various Cummins engines. This roll pin is integral to the engine’s structural integrity and operational efficiency. It is designed to secure different parts within the engine, ensuring that they remain in place under the high stress and dynamic conditions of engine operation.

Application in Cummins Engines

The Roll Pin 4989847 is utilized across multiple Cummins engine models, including but not limited to:

- B3.3 Series

- The B3.3 engine series benefits from the roll pin’s ability to maintain alignment and stability in critical engine components. This ensures smooth operation and longevity of the engine.

Importance of the Roll Pin

The roll pin’s role in engine assembly cannot be overstated. It provides:

- Secure Fastening: By locking parts in place, it prevents unwanted movement that could lead to mechanical failure.

- Load Distribution: It helps in distributing loads evenly, reducing wear and tear on engine parts.

- Ease of Maintenance: The roll pin allows for easy disassembly and reassembly, facilitating maintenance and repair processes.

Compatibility and Usage

The Roll Pin 4989847 is engineered to fit seamlessly within the specified engine models. Its design ensures compatibility with the engine’s architecture, providing a reliable connection point for various components. This compatibility is crucial for maintaining the engine’s performance and reliability.

Role of Part 4989847 Roll Pin in Engine Systems

The part 4989847 Roll Pin is an essential component in ensuring the smooth operation of various engine systems. In the Housing, the Roll Pin secures components in place, allowing for precise alignment and reducing the risk of misalignment during engine operation. This is particularly important in maintaining the integrity of the housing’s structural components.

In conjunction with the Front Gear, the Roll Pin facilitates the proper meshing of gear teeth. This ensures efficient power transmission from the gear to other engine components, contributing to the overall performance and reliability of the engine system.

Within the Long Block, the Roll Pin plays a significant role in maintaining the alignment of rotating components. By securing these parts in place, it helps to ensure consistent engine performance and reduces wear on other components, thereby enhancing the longevity of the engine.

Conclusion

The Cummins 4989847 Roll Pin is a vital component in the operation and maintenance of commercial trucks and Cummins engines. Its role in securing critical components, ensuring alignment, and contributing to the overall performance and reliability of these systems cannot be overstated. Regular maintenance and proper installation are key to maximizing the benefits of this part, ensuring the longevity and efficiency of commercial vehicles.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.