This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

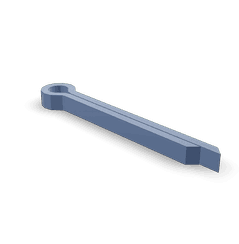

The 4944456 Cotter Pin Fastener, manufactured by Cummins, is a specialized component designed for use in commercial truck applications. Cummins, a well-established name in the automotive industry, is known for its commitment to quality and innovation. This Cummins part is significant in the realm of truck maintenance and operation, providing a reliable solution for securing various components within the vehicle.

Basic Concepts of Cotter Pin Fasteners

A cotter pin fastener is a simple yet effective mechanical device used to secure components by preventing them from loosening or disconnecting. Typically made of metal, cotter pins are inserted through holes in connected parts and then bent to create a secure fit. This mechanism ensures that the components remain in place under operational stress, contributing to the overall safety and efficiency of the machinery 1.

Purpose of the 4944456 Cotter Pin Fastener in Truck Operations

The 4944456 Cotter Pin Fastener plays a specific role in the operation and maintenance of commercial trucks. It is utilized in various applications where secure fastening is required, such as in the attachment of wheel bearings, securing bolts, and other critical components. Its function is to maintain the integrity of these connections, ensuring that they do not loosen during operation, which could lead to potential safety hazards or mechanical failures 2.

Key Features of the 4944456 Cotter Pin Fastener

The 4944456 Cotter Pin Fastener is characterized by several key features that enhance its performance and reliability. It is constructed from high-quality materials, ensuring durability and resistance to wear and corrosion. The design specifications of this fastener include precise dimensions and a robust structure, allowing it to withstand the rigors of commercial truck operations. Additionally, the fastener may possess unique attributes such as a pre-bent shape for easier installation or a coated surface to further protect against environmental factors 3.

Benefits of Using the 4944456 Cotter Pin Fastener

Utilizing the 4944456 Cotter Pin Fastener offers several advantages. Its durable construction ensures long-term reliability, reducing the need for frequent replacements. The ease of installation is another benefit, as the fastener can be quickly and securely fitted without the need for complex tools. Furthermore, by maintaining secure connections, the 4944456 Cotter Pin Fastener contributes to the overall integrity of the truck’s systems, enhancing safety and performance 4.

Installation and Usage Guidelines

Proper installation of the 4944456 Cotter Pin Fastener involves a few straightforward steps. First, ensure that the components to be fastened are correctly aligned. Insert the cotter pin through the designated holes, making sure it passes completely through. Using pliers, bend the ends of the pin to secure it in place, ensuring that the bend is tight and secure. It is important to use the correct tools and follow best practices to ensure a secure fastening 5.

Troubleshooting Common Issues

Common issues with cotter pin fasteners include loosening over time or corrosion, which can compromise their effectiveness. To address these problems, regular inspections should be conducted to check for any signs of wear or damage. If a fastener is found to be loose, it should be replaced immediately. Corrosion can be mitigated by using fasteners made from corrosion-resistant materials or by applying a protective coating 6.

Maintenance Tips

Regular maintenance of the 4944456 Cotter Pin Fastener is crucial to ensure its continued effectiveness. Inspections should be performed at regular intervals to check for any signs of wear, damage, or corrosion. Cleaning the fastener and its surrounding area can help prevent the buildup of dirt and debris, which can contribute to corrosion. If any issues are detected, the fastener should be replaced to maintain the integrity of the connection 7.

Safety Considerations

When working with the 4944456 Cotter Pin Fastener, it is important to observe certain safety guidelines. Always wear appropriate personal protective equipment (PPE) to protect against injury. Ensure that the truck is securely parked and the engine is off before beginning any maintenance or installation work. Follow all manufacturer guidelines and best practices to ensure the safety of personnel and the integrity of the truck’s components 8.

Compatibility of Part 4944456 with Cummins Engines

The 4944456, a Cotter Pin Fastener manufactured by Cummins, is designed to be compatible with a range of Cummins engines. This part is integral in securing various components within the engine, ensuring stability and safety during operation. Here is a detailed look at its compatibility with specific engine models:

B3.3 Engine

The B3.3 engine is a compact, reliable power source often used in various applications. The Cotter Pin Fastener 4944456 is engineered to fit seamlessly within the B3.3 engine, providing a secure fastening solution for critical components. This ensures that parts remain in place under the stress of engine operation, contributing to the engine’s overall durability and performance.

QSB3.3 CM2150 and QSB3.3 CM2250 EC Engines

The QSB3.3 CM2150 and QSB3.3 CM2250 EC engines are part of Cummins’ QSB series, known for their robust design and efficiency. The Cotter Pin Fastener 4944456 is specifically designed to meet the stringent requirements of these engines. It is used in various applications within the engine, including securing belts, brackets, and other movable parts. This ensures that the engine operates smoothly and efficiently, with all components held firmly in place.

The EC variant of the QSB3.3 CM2250 engine, which is equipped with an electronic control system, also benefits from the precise fit and function of the Cotter Pin Fastener 4944456. This part’s compatibility with the electronic control system ensures that the engine’s advanced features are not compromised, maintaining the integrity of the engine’s performance.

Role of Part 4944456 Cotter Pin Fastener in Engine Systems

In the context of engine systems, the 4944456 Cotter Pin Fastener is instrumental in ensuring the secure assembly and operation of various components. Specifically, it plays a significant role in the lubricating oil pump and its associated parts.

Lubricating Oil Pump

The lubricating oil pump is a vital component responsible for circulating oil throughout the engine to reduce friction and wear on moving parts. The 4944456 Cotter Pin Fastener is used to secure the lubricating oil pump to its mounting points, ensuring that it remains firmly in place during operation. This stability is essential for the pump to function correctly, delivering consistent oil pressure to critical engine components.

Lubricating Oil Pump Cover

The lubricating oil pump cover encases the pump mechanism, protecting it from contaminants and ensuring that oil is directed efficiently. The 4944456 Cotter Pin Fastener is employed to fasten the cover to the pump body. This connection must be secure to prevent any oil leaks, which could lead to insufficient lubrication and potential engine damage.

Pump Assembly

Within the pump assembly, various shafts and gears work in unison to create the necessary oil pressure. The 4944456 Cotter Pin Fastener is often used to secure these internal components, ensuring they remain aligned and function smoothly. Proper alignment and secure fastening are essential for the efficient operation of the pump.

Lubricating Oil System

The overall lubricating oil system relies on the integrity of each component to maintain optimal engine performance. The 4944456 Cotter Pin Fastener contributes to this by providing a reliable means of fastening critical parts together. Its role in securing the lubricating oil pump and cover ensures that the system operates as intended, delivering the necessary lubrication to engine components under various operating conditions.

Conclusion

The 4944456 Cotter Pin Fastener is a crucial component in the maintenance and operation of commercial trucks and Cummins engines. Its durable construction, ease of installation, and reliable performance make it an essential part for securing various components within the vehicle. Regular maintenance and proper installation are key to ensuring the continued effectiveness of this fastener, contributing to the overall safety and efficiency of the machinery.

References

-

Schuetz, T. (2016). Aerodynamics of Road Vehicles: Fifth Edition. SAE International.

↩ -

Hiereth, H., Prenninger, P., & Drexl, K. W. (2010). Charging the Internal Combustion Engine. Springer.

↩ -

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩ -

Fischer, R., Kucukay, F., Jurgens, G., Najork, R., & Pollak, B. (2015). The Automotive Transmission Book Powertrain. Springer.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for 6.7N CM2380 D109B. Bulletin Number 5676938.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for 6.7N CM2380 D109B. Bulletin Number 5676938.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for 6.7N CM2380 D109B. Bulletin Number 5676938.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for 6.7N CM2380 D109B. Bulletin Number 5676938.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.