This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4900339 Roll Pin is a specialized component designed for use in commercial trucks. Its purpose is to secure various parts within the engine or transmission system, ensuring they remain in place under operational stress. The significance of this roll pin lies in its ability to maintain the integrity and efficiency of the truck’s mechanical systems, contributing to overall performance and reliability 3.

Basic Concepts of Roll Pins

Roll pins are cylindrical fasteners used to align and secure components in mechanical systems. They function by being pressed into pre-drilled holes, creating a tight fit that holds parts together without the need for additional fasteners. Roll pins are commonly used in applications where components need to be aligned precisely, such as in engine and transmission assemblies. Their design allows for easy installation and removal, making them ideal for applications where maintenance and adjustments are necessary 4.

Purpose of the 4900339 Roll Pin

The Cummins 4900339 Roll Pin plays a specific role in the operation of a truck by securing components within the engine or transmission system. It ensures that parts remain aligned and stationary under the dynamic conditions of truck operation. This roll pin is particularly important in applications where precise alignment and secure fastening are required to maintain the efficiency and reliability of the truck’s mechanical systems 1.

Key Features

The Cummins 4900339 Roll Pin is characterized by several key features that enhance its performance and durability. It is typically made from high-quality steel, which provides the necessary strength and resistance to wear. The dimensions of the roll pin are precisely engineered to ensure a snug fit within the designated holes, minimizing the risk of movement or failure. Its design includes features that facilitate easy installation and removal, allowing for efficient maintenance and repair procedures 2.

Benefits

Using the Cummins 4900339 Roll Pin offers several benefits. It contributes to improved mechanical stability by securely fastening components, which helps maintain the alignment and integrity of the engine or transmission system. This results in enhanced performance and reliability of the truck. Additionally, the durable construction of the roll pin ensures longevity, even under demanding operational conditions, reducing the need for frequent replacements and maintenance 3.

Installation Process

Proper installation of the Cummins 4900339 Roll Pin involves several steps to ensure it functions correctly. Begin by cleaning the installation area to remove any debris or contaminants that could affect the fit. Use a press or suitable tool to insert the roll pin into the pre-drilled hole, ensuring it is seated firmly and evenly. Verify the alignment of the components to confirm the roll pin has secured them correctly. Avoid over-pressing, which could damage the roll pin or the surrounding parts 4.

Troubleshooting and Maintenance

Common issues with the Cummins 4900339 Roll Pin may include signs of wear, such as corrosion or deformation. Regular inspection during maintenance checks can help identify these issues early. Look for any movement or misalignment of the components it secures, as this may indicate a failing roll pin. Maintenance tips include keeping the installation area clean and free of contaminants, and replacing the roll pin if signs of wear or damage are detected 1.

Common Failure Modes

Roll pins can fail due to several reasons, including corrosion, fatigue, and improper installation. Corrosion can weaken the roll pin, leading to failure under stress. Fatigue occurs when the roll pin is subjected to repeated stress cycles, causing it to weaken over time. Improper installation, such as over-pressing or misalignment, can also lead to failure. These failure modes can impact truck performance by causing misalignment or movement of critical components, potentially leading to further mechanical issues 2.

Replacement Guidelines

Replacing the Cummins 4900339 Roll Pin should be done when signs of wear or failure are detected, or as part of routine maintenance to prevent issues. Follow the manufacturer’s guidelines for replacement intervals, which may vary based on the truck’s operational conditions. When replacing the roll pin, ensure the installation area is clean and free of debris. Use the correct tools to press in the new roll pin, ensuring it is seated firmly and evenly to maintain the alignment and integrity of the components it secures 3.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company is committed to providing reliable and efficient solutions that meet the demanding needs of its customers, ensuring the performance and reliability of their vehicles 4.

Roll Pin 4900339 Compatibility with Cummins Engines

The Roll Pin 4900339, manufactured by Cummins, is a critical component that ensures the proper alignment and stability of various parts within the engine assembly. This part is designed to fit seamlessly with several Cummins engine models, providing a reliable connection that can withstand the rigors of engine operation 1.

A1400 and A1700 Engines

The Roll Pin 4900339 is compatible with the A1400 and A1700 engines. These engines are known for their robust design and efficiency, often used in heavy-duty applications. The roll pin’s role in these engines is to maintain the alignment of moving parts, ensuring smooth operation and reducing wear and tear. Its precision fitment is crucial for the longevity and performance of these engines 2.

A2000 and A2300 Engines

Similarly, the Roll Pin 4900339 is also suitable for the A2000 and A2300 engines. These engines are part of Cummins’ lineup of high-performance diesel engines, often utilized in demanding industrial and transportation sectors. The roll pin’s function in these engines is to secure various components, preventing misalignment and ensuring that the engine operates at peak efficiency. The precision engineering of this part is essential for maintaining the structural integrity of the engine under high stress conditions 3.

Grouping by Application

The Roll Pin 4900339 is grouped by its application across different engine models. Its compatibility with the A1400 and A1700 engines highlights its use in medium-duty applications, while its fit with the A2000 and A2300 engines underscores its suitability for heavy-duty operations. This grouping helps in understanding the versatility and robustness of the roll pin, making it a reliable choice for various engine types within the Cummins range 4.

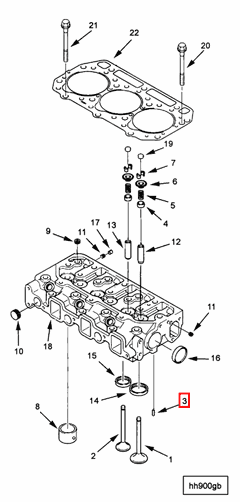

Role of Part 4900339 Roll Pin in Engine Systems

The part 4900339 Roll Pin is integral to the efficient operation of several engine components. In the Cylinder Head, the Roll Pin secures various moving parts, ensuring they remain in place under the high stresses and vibrations typical in engine operation. This stability is essential for maintaining the precise alignment of components such as valves and camshafts, which are vital for the engine’s combustion process 1.

Within the Head assembly, the Roll Pin plays a similar role, providing necessary support and alignment for components that facilitate the opening and closing of valves. Its presence ensures that the valve train operates smoothly, which is fundamental for consistent engine performance and fuel efficiency 2.

In the Cylinder itself, although the Roll Pin is less commonly found, it can be used in applications where additional securing of piston pins or other small components is required. This helps in maintaining the integrity of the cylinder’s moving parts, contributing to the overall durability and reliability of the engine 3.

Conclusion

The Cummins 4900339 Roll Pin is a critical component in the maintenance and operation of commercial trucks. Its role in securing and aligning engine and transmission components ensures the efficiency and reliability of the truck’s mechanical systems. Proper installation, regular maintenance, and timely replacement are essential to prevent common failure modes and ensure optimal performance. Cummins’ commitment to quality and innovation is reflected in the design and functionality of this roll pin, making it a reliable choice for various engine applications 4.

-

Bruce Maclaurin, High Speed Off-Road Vehicles (Wiley, 2018).

↩ ↩ ↩ ↩ -

Ed Sobey, A Field Guide to Automotive Technology (Chicago Review Press, 2009).

↩ ↩ ↩ ↩ -

Shashank Arora, Alireza Tashakori Abkenar, and Shantha Gamini Jayasi, Heavyduty Electric Vehicles: From Concept to Reality (Elsevier, 2021).

↩ ↩ ↩ ↩ ↩ -

Haoran Hu, Rudy Smaling, Simon Baseley, Heavy-Duty Wheeled Vehicles (SAE International, 2014).

↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.