This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4900284 Guide Pin is a component designed to facilitate the smooth operation of commercial trucks. Its role is integral to the mechanical systems of these vehicles, ensuring efficient and reliable performance. Understanding its purpose and significance can provide valuable insights into the maintenance and operation of commercial trucks.

Basic Concepts of Guide Pins

Guide pins are mechanical components used to align and stabilize moving parts within machinery. They play a role in ensuring precise movement and reducing friction between components. In the context of trucks, guide pins contribute to the smooth operation of various mechanical systems by maintaining alignment and minimizing wear on interacting parts 1.

Purpose of the 4900284 Guide Pin

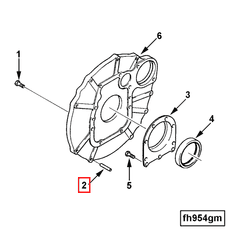

This Cummins part is specifically designed to support the operation of trucks by guiding and stabilizing certain mechanical components. It ensures that parts move correctly within the system, which is vital for the overall efficiency and reliability of the truck’s mechanical operations. This guide pin is part of a system that requires accurate alignment and smooth movement to function optimally 2.

Key Features

The 4900284 Guide Pin is characterized by its robust design and high-quality material composition. It is crafted from durable materials to withstand the rigors of commercial truck operations. Its design includes features that enhance its performance, such as a precise fit and smooth surface, which contribute to reduced friction and wear 3.

Benefits of Using the 4900284 Guide Pin

Incorporating this part into truck operations offers several advantages. It contributes to improved efficiency by ensuring components move smoothly and accurately. Its durable construction enhances the reliability of the truck’s mechanical systems, leading to reduced downtime and maintenance costs. Additionally, the guide pin’s design helps in prolonging the lifespan of interacting parts by minimizing wear.

Installation Process

Installing the 4900284 Guide Pin requires careful attention to detail to ensure proper alignment and function. The process involves preparing the area for installation, using appropriate tools to secure the guide pin in place, and verifying that it is correctly positioned. Safety precautions, such as wearing protective gear and ensuring the truck is securely supported, should be observed throughout the installation process.

Maintenance and Care

Regular maintenance and care of the 4900284 Guide Pin are crucial for ensuring its longevity and optimal performance. This includes routine cleaning to remove dirt and debris, periodic inspection for signs of wear or damage, and replacement when necessary. Proper maintenance helps in identifying potential issues early, thereby preventing more significant problems down the line.

Troubleshooting Common Issues

Common issues associated with guide pins, such as misalignment, wear, and damage, can affect the performance of truck mechanical systems. Addressing these problems involves identifying the root cause, whether it be improper installation, excessive wear, or external damage. Solutions may include realigning the guide pin, replacing worn components, or addressing external factors that contribute to damage.

Compatibility and Applications

The 4900284 Guide Pin is designed for use in specific types of trucks and models, demonstrating its versatility and widespread application in the industry. Its compatibility with various truck models underscores its importance in ensuring the smooth operation of commercial vehicles across different applications.

Cummins: A Brief Overview

Cummins Inc. is a renowned manufacturer in the commercial truck industry, known for its wide range of high-quality products. The company’s history of innovation and commitment to excellence is reflected in its product offerings, including the 4900284 Guide Pin. Cummins’ reputation for quality and reliability makes its components, like the 4900284 Guide Pin, a preferred choice for truck manufacturers and operators alike.

Role of Part 4900284 Guide Pin in Engine Systems

The 4900284 Guide Pin is an integral component in the synchronization and alignment of various engine parts, ensuring smooth operation and longevity of the engine system.

In the context of the crankshaft, the guide pin facilitates precise alignment during installation or maintenance, reducing the risk of misalignment which could lead to increased wear or failure. It ensures that the crankshaft is correctly positioned within the engine block, allowing for optimal performance and efficiency.

When considering the flywheel housing, the guide pin plays a significant role in maintaining the correct spacing and alignment between the flywheel and the crankshaft. This is essential for the efficient transfer of power from the engine to the transmission system. Proper alignment ensures that the flywheel engages smoothly with the crankshaft, minimizing vibrations and enhancing the overall stability of the engine.

Furthermore, in the engine as a whole, the guide pin contributes to the accurate assembly of components. It helps in maintaining the structural integrity of the engine by ensuring that all moving parts are correctly aligned. This not only enhances the engine’s performance but also extends its operational life by preventing premature wear and tear.

Conclusion

In summary, the 4900284 Guide Pin is a key component in the precise alignment and installation of critical engine parts, playing a significant role in the overall efficiency and reliability of the engine system. Its robust design, durable construction, and precise alignment capabilities make it an essential part for the smooth operation of commercial trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.