This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

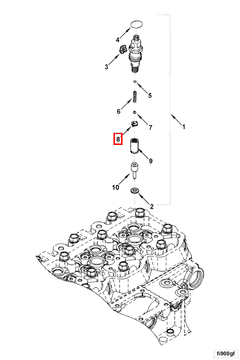

The Cummins 3917946 Pressure Spindle is a specialized component utilized in commercial truck engines. Its role within the fuel system is to regulate and maintain pressure, contributing to the engine’s performance and efficiency. Understanding its function and operation is essential for maintaining and optimizing truck engines.

Basic Concepts of Pressure Spindles

A pressure spindle is a mechanical component that regulates and maintains pressure within an engine system by controlling the flow of fuel or other fluids. This regulation is crucial for maintaining consistent power output and fuel efficiency, ensuring the engine operates optimally 1.

Purpose of the Cummins 3917946 Pressure Spindle

This Cummins part is integral to the fuel system of a truck engine, regulating the pressure of the fuel delivered to the injectors. Proper pressure regulation ensures that the fuel is atomized correctly, which is necessary for efficient combustion, affecting the engine’s power output and fuel economy 2.

Key Features

The Cummins 3917946 Pressure Spindle is characterized by its robust design and the use of high-quality materials, contributing to its durability and performance. It is engineered to withstand high pressures and temperatures within the engine compartment, ensuring reliable operation over the long term. Precision machining ensures accurate pressure regulation 3.

Benefits

Utilizing the Cummins 3917946 Pressure Spindle in a truck’s engine system offers several benefits, including improved engine efficiency by ensuring fuel is delivered at the optimal pressure. This can lead to better fuel economy and reduced emissions. Additionally, the spindle’s reliable operation enhances the overall reliability of the engine, reducing the likelihood of unexpected failures.

Installation and Integration

When installing the Cummins 3917946 Pressure Spindle, it is important to follow the manufacturer’s guidelines to ensure proper integration within the engine system. This may involve specific prerequisites, such as ensuring the engine is clean and free of debris, and that all connections are secure. Proper installation is key to ensuring the spindle functions correctly and contributes to the engine’s performance.

Troubleshooting and Maintenance

To maintain the Cummins 3917946 Pressure Spindle and ensure its longevity, regular maintenance is recommended. This includes inspecting the spindle for signs of wear or damage, and replacing it if necessary. Troubleshooting common issues may involve checking for leaks in the fuel system or ensuring that the spindle is correctly installed and functioning as intended. Regular inspections can help identify potential problems before they lead to more significant issues.

Cummins Overview

Cummins Inc. is a well-established manufacturer in the automotive industry, known for producing high-quality engine components. With a history of innovation and a commitment to excellence, Cummins has built a reputation for reliability and performance. The company’s engine components, including the Cummins 3917946 Pressure Spindle, are designed with precision and durability in mind, reflecting Cummins’ dedication to quality and customer satisfaction.

Role of 3917946 Pressure Spindle in Engine Systems

The 3917946 Pressure Spindle is integral to the efficient operation of various engine systems, particularly when integrated with injectors and injector kits. This spindle is designed to maintain consistent pressure within the fuel system, ensuring optimal performance of the injectors.

When installed in conjunction with an injector, the Pressure Spindle helps regulate the fuel pressure delivered to the combustion chamber. This regulation is essential for precise fuel delivery, which directly impacts the engine’s efficiency and power output. The spindle’s ability to maintain stable pressure conditions allows the injector to atomize fuel more effectively, leading to better combustion and reduced emissions.

In injector kits, the Pressure Spindle plays a similar role but on a broader scale. These kits often include multiple injectors designed to work in unison. The spindle ensures that each injector receives the same pressure, promoting uniform fuel distribution across all cylinders. This uniformity is vital for balanced engine performance and longevity.

For performance parts, the 3917946 Pressure Spindle is often a key upgrade. High-performance engines demand precise fuel delivery to maximize power and efficiency. The spindle’s role in maintaining consistent pressure becomes even more significant in these applications, as even minor fluctuations can lead to decreased performance and potential engine damage.

Conclusion

The Cummins 3917946 Pressure Spindle is a fundamental component in ensuring that injectors and injector kits operate within their designed parameters, thereby enhancing the overall performance and reliability of engine systems. Its role in maintaining consistent pressure within the fuel system is crucial for efficient combustion, improved fuel economy, and reduced emissions. Regular maintenance and proper installation are key to ensuring the longevity and effectiveness of this part in engine systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.