This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3863156 Cotter Pin, manufactured by Cummins, is a specialized component designed for use in commercial trucks. Cummins, a well-established name in the commercial truck industry, produces a range of high-quality parts that ensure the reliability and efficiency of truck operations. This part is integral to various mechanical systems within trucks, providing secure fastening and preventing components from loosening under operational stress. Understanding the role of cotter pins in mechanical systems is fundamental to maintaining the integrity and performance of truck assemblies.

Basic Concepts of Cotter Pins

A cotter pin is a simple yet vital component used in mechanical assemblies to secure bolts, nuts, and other fasteners. Its basic design consists of a metal pin with a bent end, which is inserted through a hole in the fastener. Once in place, the bent end prevents the fastener from rotating or loosening. Cotter pins are typically made from materials such as steel or stainless steel, chosen for their durability and resistance to corrosion. These materials ensure that the cotter pin can withstand the rigors of truck operations without degrading over time 1.

Purpose of Cotter Pin 3863156 in Truck Operations

The 3863156 plays a specific role in the operation of commercial trucks by securing critical components that are subject to vibration and movement. It is commonly used in applications such as securing wheel bearings, locking castle nuts on steering components, and fastening brake components. By preventing these parts from loosening, the cotter pin ensures the safety and reliability of the truck’s mechanical systems 2.

Key Features of Cotter Pin 3863156

The 3863156 is characterized by its robust design and precise dimensions, which are tailored to fit specific applications within truck mechanics. Its unique attributes include a durable construction that resists wear and corrosion, ensuring long-term performance. The pin’s bent end is designed to provide a secure lock, enhancing its functionality in high-stress environments.

Benefits of Using Cotter Pin 3863156

Incorporating the 3863156 into truck maintenance and repair offers several advantages. Its reliability ensures that critical components remain securely fastened, reducing the risk of mechanical failure. The ease of use and cost-effectiveness of the cotter pin make it a practical choice for truck maintenance, allowing for quick and efficient fastening solutions. Additionally, its durability contributes to the overall longevity of truck components 3.

Installation and Usage Guidelines

Proper installation of the 3863156 is crucial for ensuring secure and effective use within truck components. To install, align the pin with the hole in the fastener and insert it until the bent end locks in place. It is important to ensure that the pin is fully seated and that the bent end is properly engaged to prevent rotation. Following these guidelines will help maintain the integrity of the fastening and the performance of the truck’s mechanical systems.

Troubleshooting and Maintenance

Common issues with cotter pins in truck applications include corrosion, bending, or breakage. Regular inspection for signs of wear or damage is important to identify potential problems early. Maintenance tips for the 3863156 include keeping it clean and free from debris, replacing it if it shows signs of wear, and ensuring proper installation to prevent loosening.

Safety Considerations

When working with cotter pins, it is important to follow safety guidelines to prevent accidents and ensure component integrity. This includes proper handling to avoid injury, correct installation to secure components effectively, and regular inspection to identify and address any issues promptly. Adhering to these practices will help maintain the safety and reliability of truck operations.

Cummins: Manufacturer Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its history of innovation, extensive product range, and reputation for quality. The company’s commitment to producing reliable and efficient components has made it a preferred choice for truck manufacturers and maintenance professionals. Cummins’ expertise in engine and component design ensures that its products, like the 3863156, meet the high standards required for commercial truck applications.

Engine Compatibility for Cotter Pin 3863156 by Cummins

The 3863156, manufactured by Cummins, is a crucial component in ensuring the securement and stability of various engine parts. This pin is designed to fit seamlessly within the engine systems of the following Cummins engines:

- 4B3.9

- 6B5.9

- B3.3

These engines, while differing in their specifications and applications, share a commonality in their requirement for reliable fastening mechanisms. The 3863156 is engineered to meet the stringent demands of these engines, providing a robust solution for maintaining the integrity of engine components.

In the 4B3.9 and 6B5.9 engines, the Cotter Pin is utilized in areas where secure locking is essential to prevent accidental disengagement of parts that could lead to engine failure. Its application in these engines ensures that critical components remain firmly in place under varying operational conditions.

Similarly, the B3.3 engine benefits from the use of this Cotter Pin, particularly in scenarios where high-stress environments necessitate a dependable fastening solution. The pin’s design allows it to withstand the rigors of engine operation, providing long-lasting performance and reliability.

By incorporating the 3863156 into their maintenance and repair protocols, operators of these Cummins engines can ensure enhanced safety and operational efficiency. This part’s compatibility across multiple engine models underscores its versatility and importance in the maintenance of Cummins engine systems.

Role of Part 3863156 Cotter Pin in Engine Systems

In the context of engine systems, the 3863156 is instrumental in ensuring the secure and reliable operation of various components.

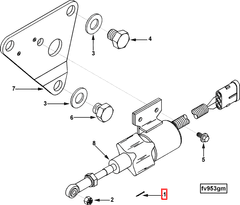

Fuel Shut-Off Valve

The Fuel Shut-Off Valve is a pivotal component in engine systems, tasked with controlling the flow of fuel to the engine. The 3863156 plays a significant role here by securing the linkage or actuator mechanism that operates the valve. This ensures that the valve remains in the desired position—whether open or closed—under varying operational conditions. The pin’s secure fit prevents any unintended movement that could lead to fuel flow irregularities.

Solenoid

Solenoids are electromagnetic devices used to control various functions within engine systems, including the activation of the Fuel Shut-Off Valve. The 3863156 is often used to secure the plunger within the solenoid, ensuring it operates smoothly and consistently. By maintaining the integrity of the solenoid’s mechanical components, the Cotter Pin contributes to the reliable activation and deactivation of the solenoid, which in turn ensures precise control over engine functions.

Valve

In a broader sense, valves within engine systems regulate the flow of fluids, gases, or other substances. The 3863156 is employed to secure various valve components, such as the stem or actuator linkage. This securement is essential for maintaining the valve’s position and ensuring it operates within specified parameters. Whether it’s a fuel valve, air intake valve, or exhaust valve, the Cotter Pin’s role is to provide a stable and reliable connection that withstands the dynamic forces encountered during engine operation.

Fuel Shutoff

The Fuel Shutoff mechanism is designed to stop the fuel supply to the engine in emergency situations or during maintenance. The 3863156 is utilized to secure the shutoff lever or linkage, ensuring that the mechanism can be engaged and disengaged reliably. This security is vital for safety and operational integrity, as it prevents any accidental fuel flow when the engine is not in operation or during critical situations.

Conclusion

In summary, the 3863156 is a small yet significant component that enhances the reliability and safety of engine systems by securing critical linkages and mechanisms across various components. Its role in preventing loosening and ensuring secure fastening is crucial for the operational integrity of commercial trucks and Cummins engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.