This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

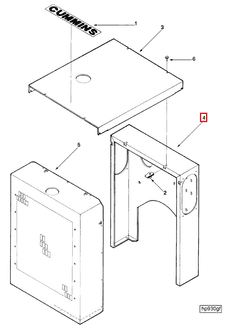

The Cummins 3922544 Back Panel is a component designed for commercial trucks, playing a significant role in the vehicle’s structural and functional integrity. This part is integral to the truck’s design, contributing to both the safety and efficiency of the vehicle.

Purpose and Function

The Cummins 3922544 Back Panel serves multiple functions within the truck’s structure. It provides a protective barrier for the rear of the engine compartment, shielding sensitive components from external elements such as debris, moisture, and impacts. Additionally, it contributes to the overall structural rigidity of the truck, ensuring that the chassis maintains its shape and strength under various driving conditions. This panel also plays a role in the truck’s aerodynamics, potentially influencing fuel efficiency by reducing air resistance 1.

Key Features

The Cummins 3922544 Back Panel is constructed from high-strength materials, ensuring durability and resistance to wear and tear. Its design incorporates precise engineering to fit seamlessly with the truck’s chassis, featuring mounting points and brackets that allow for secure installation. The panel is also designed with consideration for weight reduction, balancing the need for strength with the desire to minimize the truck’s overall weight for better fuel efficiency 2.

Benefits

One of the primary advantages of the Cummins 3922544 Back Panel is its contribution to the truck’s longevity and reliability. By protecting the engine compartment, it helps prevent damage that could lead to costly repairs or downtime. Additionally, the panel’s role in the truck’s aerodynamics can lead to slight improvements in fuel efficiency, offering potential cost savings over time. The robust construction of the panel also ensures that it can withstand the rigors of commercial use, providing fleet operators with a reliable component that requires minimal maintenance 3.

Installation Process

Installing the Cummins 3922544 Back Panel requires careful attention to detail to ensure proper fitment and functionality. The process involves securing the panel to the truck’s chassis using the provided mounting hardware. It is important to use the correct tools and follow safety precautions, such as wearing protective gear and ensuring the truck is securely supported during the installation process. Detailed instructions should be followed to avoid any potential issues with the installation.

Troubleshooting and Maintenance

Common issues with the Cummins 3922544 Back Panel may include damage from impacts or corrosion over time. Regular inspections can help identify any signs of wear or damage, allowing for timely repairs or replacements. Maintenance tips include keeping the panel clean and free from debris, as well as ensuring that all mounting hardware is secure and in good condition. Following these practices can help ensure the longevity and optimal performance of the panel.

Regulatory Compliance

The Cummins 3922544 Back Panel is designed to meet industry standards for safety and performance. It complies with relevant regulatory requirements, ensuring that it can be used with confidence in commercial applications. This compliance helps ensure that the panel not only protects the truck’s components but also contributes to the overall safety and reliability of the vehicle.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history of innovation and a strong reputation in the commercial truck industry, Cummins is known for producing high-quality components that enhance the performance and reliability of commercial vehicles. The company’s commitment to excellence is reflected in its products, including the Cummins 3922544 Back Panel.

Cummins Back Panel 3922544 Compatibility

The Cummins Back Panel, part number 3922544, is designed to fit seamlessly within a range of engine configurations. This component is integral to the structural integrity and operational efficiency of the engines it supports.

Engine Group: 4B3.9

The 4B3.9 engine series is one of the primary beneficiaries of the Back Panel 3922544. This part is engineered to align perfectly with the design specifications of the 4B3.9 engines, ensuring a secure fit and optimal performance. The back panel plays a role in protecting the internal components of the engine from external elements, thereby enhancing the longevity and reliability of the engine.

Engine Group: 6CT8.3

Similarly, the 6CT8.3 engine series also incorporates the Back Panel 3922544. This part is meticulously crafted to match the unique contours and requirements of the 6CT8.3 engines. The back panel’s precision fit ensures that it effectively shields the engine’s internals, contributing to the overall efficiency and durability of the engine.

Engine Group: QSK19

The QSK19 engine series is another beneficiary of the Back Panel 3922544. This part is designed to integrate smoothly with the QSK19 engines, providing a robust barrier against wear and tear. The back panel’s design ensures that it complements the engine’s architecture, facilitating smooth operation and maintenance.

Engine Group: L10

Lastly, the L10 engine series also utilizes the Back Panel 3922544. This part is engineered to fit the specific dimensions and needs of the L10 engines, ensuring that it provides the necessary protection and support. The back panel’s precision engineering guarantees that it aligns perfectly with the engine, contributing to its overall performance and lifespan.

Role of Part 3922544 Back Panel in Engine Systems

The back panel, identified by part number 3922544, serves as a foundational element in the assembly and operation of engine systems. It is integral to the structural integrity and functional efficiency of the enclosure, which houses various engine components.

Integration with the Enclosure

The back panel is meticulously designed to fit snugly within the enclosure, providing a secure backdrop for the installation of multiple engine components. Its placement ensures that the enclosure maintains its shape and structural stability, which is essential for the safe operation of the engine. The panel also aids in the organization of wiring and tubing, preventing potential tangling or damage that could lead to engine malfunction.

Support for Product Components

Within the enclosure, the back panel supports the mounting of various product components, such as sensors, control modules, and other electronic devices. These components rely on the back panel for a stable platform, ensuring they remain in the correct position and orientation. This stability is vital for the accurate reading and transmission of data, which is crucial for the engine’s performance and diagnostic capabilities.

Facilitation of Airflow and Cooling

The back panel also plays a role in the management of airflow within the enclosure. By providing a defined space and structure, it helps in directing air towards heat-generating components, aiding in their cooling. This is particularly important for maintaining optimal operating temperatures and preventing overheating, which can lead to reduced engine efficiency or failure.

Enhancement of Electrical Integrity

Electrical components within the engine system benefit from the back panel’s presence. It provides a grounded surface that can help in reducing electromagnetic interference (EMI), ensuring that sensitive electronic components function correctly. This is especially important in modern engines where electronic control units (ECUs) and other digital systems are prevalent.

Conclusion

In summary, the Cummins 3922544 Back Panel is a key component in the assembly and operation of engine systems, contributing to the structural integrity, component support, airflow management, and electrical integrity within the enclosure. Its robust construction, precise engineering, and compatibility with various engine configurations make it a reliable and essential part for commercial trucks.

-

Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles, Andrew Brown Jr, National Academy of Sciences, 2010.

↩ -

Controlling Noise and Vibration in Road Vehicles, Matthew Harrison, SAE International, 2004.

↩ -

Offroad Vehicle Dynamics Analysis Modelling and Optimization, Hamid Taghavifar and Aref Mardani, Springer, 2017.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.