5341385

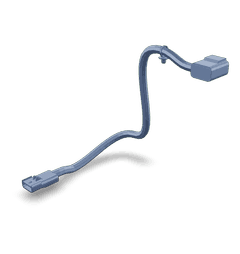

Wiring Harness

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 5341385 Wiring Harness, manufactured by Cummins, is a vital component in the electrical system of commercial trucks. Cummins, a well-established name in the commercial truck industry, produces a range of high-quality parts designed to enhance the performance and reliability of heavy-duty vehicles. This part ensures the efficient and safe transmission of electrical power and signals throughout the vehicle.

Basic Concepts of Wiring Harnesses

A wiring harness is an assembly of wires, connectors, and sometimes switches and relays that transmit electrical power and signals between various components of a vehicle. It consists of multiple wires bundled together, often secured with tape or conduit, and includes connectors that link to different parts of the vehicle’s electrical system. The primary function of a wiring harness is to organize and protect the wires, ensuring they are routed correctly and remain secure, which is crucial for the proper operation of the vehicle’s electrical systems 1.

Role of the 5341385 Wiring Harness in Truck Operation

The 5341385 Wiring Harness plays a specific role in the electrical system of a commercial truck by facilitating the connection between the engine control module (ECM) and various sensors and actuators. It ensures that electrical signals are accurately transmitted, allowing the ECM to monitor and control engine functions. This harness interacts with other components such as the fuel injectors, throttle position sensor, and other critical systems, contributing to the overall performance and efficiency of the truck 2.

Key Features of the 5341385 Wiring Harness

The 5341385 Wiring Harness is designed with several key features that enhance its functionality and durability. It is constructed using high-quality materials that are resistant to wear, corrosion, and environmental factors commonly encountered in commercial truck operations. The harness is engineered to meet stringent industry standards, ensuring reliable performance. Additionally, it includes robust connectors and terminals that provide secure and stable connections, minimizing the risk of electrical faults 3.

Benefits of Using the 5341385 Wiring Harness

Utilizing the 5341385 Wiring Harness offers several benefits in truck operations. It contributes to improved efficiency by ensuring that electrical signals are transmitted accurately and promptly. This results in better engine performance and fuel efficiency. The harness also enhances reliability by reducing the likelihood of electrical failures, which can lead to downtime and increased maintenance costs. Furthermore, it improves safety by maintaining stable and secure electrical connections, which is critical in preventing accidents caused by electrical malfunctions.

Installation Considerations

Proper installation of the 5341385 Wiring Harness is crucial for its effective functioning. It is important to follow the manufacturer’s guidelines to ensure that the harness is correctly routed and secured within the truck. This may involve using specific tools and ensuring that all connections are tight and free from damage. Additionally, it is advisable to perform a thorough inspection of the harness before installation to check for any defects or issues that could affect its performance.

Maintenance and Troubleshooting

Regular maintenance of the 5341385 Wiring Harness is important to ensure its longevity and reliable operation. This includes periodic inspections for signs of wear, corrosion, or damage. Any issues should be addressed promptly to prevent further deterioration. Common troubleshooting steps involve checking the connections for tightness and inspecting the wires for any signs of fraying or damage. Preventive measures such as keeping the harness clean and protected from environmental factors can also help maintain its condition.

Compatibility and Applications

The 5341385 Wiring Harness is designed for specific types of trucks and engines, ensuring optimal performance and compatibility. It is suited for use in various commercial truck applications, providing the necessary electrical connections for efficient operation. Understanding the specific applications and compatibility of the harness is important for ensuring it is used correctly and effectively in the intended vehicle.

Safety Precautions

When working with the 5341385 Wiring Harness, it is important to observe several safety precautions. Electrical safety practices should be followed to prevent the risk of electrical shock or injury. This includes ensuring that the vehicle’s battery is disconnected before beginning any work on the harness. Additionally, using insulated tools and wearing appropriate personal protective equipment (PPE) can help mitigate risks associated with electrical work.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its high-quality engines and components. Founded in 1919, Cummins has a long history of innovation and excellence, producing a wide range of products that enhance the performance and reliability of heavy-duty vehicles. The company is renowned for its commitment to quality and customer satisfaction, making it a trusted name in the industry.

Cummins Wiring Harness 5341385 Compatibility

The Cummins Wiring Harness part number 5341385 is designed to integrate seamlessly with specific engine models, ensuring reliable electrical connectivity and optimal performance. This wiring harness is compatible with the following Cummins engines:

- QSB6.7 CM2350 B105

- QSL9 CM2350 L102

These engines, while distinct in their applications and configurations, share a commonality in their electrical systems, which allows the 5341385 wiring harness to be universally applicable across both models. The harness is engineered to meet the stringent requirements of these engines, providing a robust and dependable solution for maintaining electrical integrity and facilitating smooth operation.

The compatibility of the 5341385 wiring harness with these engines underscores Cummins’ commitment to offering parts that are both versatile and reliable, ensuring that users can maintain their equipment with confidence.

Role of Part 5341385 Wiring Harness in Engine Systems

The part 5341385 Wiring Harness is an essential component that facilitates the electrical connections within various engine systems. Its primary function is to ensure reliable and efficient communication between the engine control unit (ECU) and other critical components.

Integration with the Turbocharger

When integrated with a turbocharger, the 5341385 Wiring Harness plays a significant role in managing the electrical signals that control the turbocharger’s operation. It connects the turbocharger’s actuator, which may be either electric or pneumatic, to the ECU. This connection allows the ECU to monitor and adjust the turbocharger’s performance in real-time based on engine load, RPM, and other operating conditions.

The harness ensures that the turbocharger receives the correct voltage and current, enabling it to respond swiftly to changes in engine demand. This results in optimized air intake, improved combustion efficiency, and ultimately, enhanced overall engine performance.

Additional Component Interactions

Beyond the turbocharger, the 5341385 Wiring Harness also interfaces with several other engine components:

-

Sensors: It connects various sensors, such as the mass airflow sensor, oxygen sensor, and manifold absolute pressure sensor, to the ECU. This allows the ECU to gather precise data on air-fuel mixture, exhaust emissions, and engine pressure, enabling it to make accurate adjustments.

-

Actuators: The harness links actuators like the fuel injectors, idle air control valve, and variable valve timing solenoid to the ECU. This ensures that the ECU can control fuel delivery, idle speed, and valve timing with precision.

-

Ignition System: It provides the necessary connections for the ignition coils and spark plugs, allowing the ECU to manage ignition timing and ensure optimal combustion.

-

Emission Control Systems: The harness facilitates the operation of components like the EGR (Exhaust Gas Recirculation) valve and catalytic converter, helping the engine meet emissions standards while maintaining performance.

In summary, the 5341385 Wiring Harness is a fundamental element in the electrical architecture of modern engine systems, ensuring seamless communication and control across a variety of components.

Conclusion

The 5341385 Wiring Harness by Cummins is a critical component in the electrical systems of commercial trucks, ensuring efficient and reliable operation. Its design, featuring high-quality materials and robust connectors, contributes to the overall performance and safety of the vehicle. Proper installation, regular maintenance, and adherence to safety precautions are essential for maximizing the benefits of this Cummins part. Understanding its compatibility and role within engine systems further highlights its importance in modern automotive applications.

-

Fehan, Douglas R. Design of Racing and High-Performance Engines 2004-2013. SAE International, 2013.

↩ -

Hilgers, Michael and Achenbach, Wilfried. Vocational Vehicles and Applications. Springer Vieweg, 2021.

↩ -

Sully, F. K. Motor Vehicle Mechanics Textbook, Fifth Edition. Heinemann Professional Publishing, 1998.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.