This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Wiring harnesses are integral components in the electrical systems of vehicles, including commercial trucks. They serve as the organized assembly of wires, connectors, and terminals that facilitate the transmission of electrical power and signals between various components. In commercial trucks, wiring harnesses are particularly vital due to the complexity and scale of the electrical systems involved. They ensure that all electrical components, from the engine control unit to lighting and auxiliary systems, are properly connected and function cohesively 1.

Purpose of the 5341383 Wiring Harness

The 5341383 Wiring Harness by Cummins is designed to play a specific role in the electrical system of a truck. It integrates with other electrical components and systems to ensure seamless operation. This harness is responsible for routing power and signals to critical components, ensuring that they receive the necessary electrical input to function correctly. Its design allows for efficient management of the electrical connections, reducing the risk of shorts and improving overall system reliability 2.

Key Features of the 5341383 Wiring Harness

The 5341383 Wiring Harness incorporates several unique features that enhance its performance and reliability. It is constructed using high-quality materials that are resistant to wear, corrosion, and environmental factors commonly encountered in commercial truck operations. The design includes advanced technologies such as integrated circuit protection and optimized wire routing, which contribute to its durability and efficiency. These features ensure that the harness can withstand the rigors of heavy-duty use while maintaining optimal performance 3.

Benefits of Using the 5341383 Wiring Harness

Utilizing the 5341383 Wiring Harness offers several advantages. It contributes to improved efficiency by ensuring that electrical connections are secure and reliable, reducing the likelihood of power loss or signal interference. The harness also reduces maintenance needs due to its robust construction and advanced features, which minimize the occurrence of faults. Additionally, it enhances safety by providing a stable and consistent electrical supply to critical components, thereby supporting the overall performance and reliability of the truck 2.

Installation Considerations

When installing the 5341383 Wiring Harness, it is important to follow guidelines and best practices to ensure optimal functionality and longevity. Proper handling is crucial to avoid damage to the wires and connectors. Routing the harness correctly helps prevent interference with other components and reduces the risk of abrasion or chafing. Securing the harness in place with appropriate fasteners ensures that it remains stable and protected during operation. Attention to these details during installation contributes to the harness’s effectiveness and durability 1.

Troubleshooting Common Issues

Identifying and resolving common problems associated with the 5341383 Wiring Harness involves a systematic approach. Diagnostic tips include checking for signs of wear or damage on the wires and connectors, ensuring that all connections are secure, and verifying that the harness is routed correctly. Regular maintenance checks can help prevent future issues by allowing for early detection of potential problems. Addressing these issues promptly helps maintain the integrity of the electrical system and ensures continued reliable operation 3.

Regular Maintenance Practices

To keep the 5341383 Wiring Harness in optimal condition, routine maintenance is recommended. This includes regular inspection intervals to check for any signs of wear, corrosion, or damage. Cleaning the harness and its connections can prevent the buildup of dirt and debris, which may cause interference. Knowing when to consider replacements is also important, as prolonged use or exposure to harsh conditions can degrade the harness over time. Adhering to these maintenance practices helps ensure the longevity and reliability of the wiring harness 1.

Cummins: A Brief Overview

Cummins Inc. is a well-established manufacturer in the commercial truck industry, known for its commitment to quality and innovation. The company offers a wide range of products, including engines, filtration systems, and aftermarket parts. Cummins’ reputation is built on its dedication to producing reliable and high-performance components. The 5341383 Wiring Harness is a testament to this commitment, incorporating advanced design and materials to meet the demanding requirements of commercial truck applications 2.

Cummins Engine Wiring Harness 5341383

The Cummins Wiring Harness 5341383 is a critical component designed to integrate seamlessly with various Cummins engines, ensuring efficient and reliable electrical connectivity. This wiring harness is engineered to fit specific engine models, providing a robust solution for managing electrical systems within these engines.

QSB6.7 CM2350 B105

The QSB6.7 CM2350 B105 engine is one of the models that benefit from the 5341383 wiring harness. This engine is known for its durability and performance, often used in heavy-duty applications. The wiring harness is tailored to interface with the engine’s electrical architecture, ensuring that all necessary connections are made without compromising the engine’s operational integrity 2.

Grouping of Engines

The Cummins Wiring Harness 5341383 is designed to be compatible with a range of engines, including but not limited to the QSB6.7 CM2350 B105. This versatility allows for a standardized approach to wiring, simplifying maintenance and repair processes. By using a single wiring harness across multiple engine models, technicians can reduce inventory costs and streamline the repair process 2.

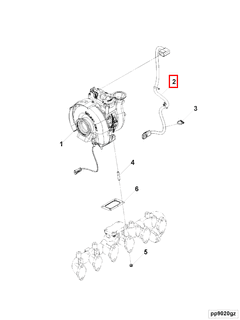

Role of Part 5341383 Wiring Harness in Engine Systems

The 5341383 Wiring Harness is an integral component in the electrical system of engine assemblies, particularly when integrated with a turbocharger. This wiring harness facilitates the connection between various electrical components and the engine control unit (ECU), ensuring seamless communication and operation 3.

Integration with Turbocharger

When paired with a turbocharger, the 5341383 Wiring Harness plays a significant role in managing the electrical signals that control the turbocharger’s operation. It connects sensors such as the turbocharger speed sensor and the boost pressure sensor to the ECU. These sensors provide real-time data on the turbocharger’s performance, allowing the ECU to make necessary adjustments to maintain optimal engine performance and efficiency 3.

Electrical Connections

The wiring harness also establishes connections to other critical components such as the wastegate actuator, which controls the turbocharger’s boost levels. By providing a reliable electrical pathway, the harness ensures that the wastegate actuator receives the correct signals from the ECU, enabling precise control over the turbocharger’s operation 3.

Sensor Integration

In addition to the turbocharger, the 5341383 Wiring Harness interfaces with various other sensors throughout the engine system. These include the mass airflow sensor, oxygen sensors, and manifold absolute pressure sensor. Each of these sensors plays a role in monitoring different aspects of engine performance, and the wiring harness ensures that the data from these sensors is accurately transmitted to the ECU 3.

Actuator Control

The harness also facilitates the control of actuators within the engine system. For instance, it connects to the fuel injectors, allowing the ECU to regulate fuel delivery based on the data received from the sensors. This ensures that the engine operates efficiently under varying conditions 3.

Overall System Reliability

By providing a robust and organized electrical connection system, the 5341383 Wiring Harness contributes to the overall reliability and performance of the engine. It reduces the risk of electrical faults and ensures that all components within the engine system can communicate effectively with the ECU 3.

Conclusion

The 5341383 Wiring Harness by Cummins is a critical component in the electrical systems of commercial trucks, ensuring efficient and reliable operation of various engine components. Its advanced design, high-quality materials, and integration capabilities make it an essential part of maintaining the performance and reliability of heavy-duty engines. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part, ensuring long-term durability and efficiency in commercial truck applications.

-

Bell, Joseph A. Modern Diesel Technology Electricity Electronics. Delmar Cengage Learning, 2014.

↩ ↩ ↩ -

Bennett, Sean, and Ian Andrew Norman. Heavy Duty Truck Systems Fifth Edition. Delmar Cengage Learning, 2011.

↩ ↩ ↩ ↩ ↩ -

Fijalkowski, BT. Automotive Mechatronics Operational and Practical Issues Volume 1. Springer, 2011.

↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.