This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

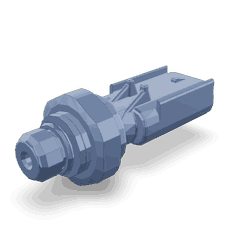

The Cummins 4358810 Pressure Sensor is designed to monitor and measure pressure levels within various systems of a commercial truck. It provides accurate pressure readings that contribute to the efficient and safe operation of the vehicle. This sensor is significant in commercial truck operations for delivering precise data that aids in maintaining optimal performance and ensuring the longevity of the truck’s systems.

Basic Concepts of Pressure Sensors

A pressure sensor measures pressure exerted by gases or liquids, converting it into an electrical signal for interpretation by electronic systems. It operates using a diaphragm or piezoelectric material that deforms under pressure, generating a measurable signal. Types of pressure sensors include absolute, gauge, differential, and compound sensors, each suited for specific applications across industries such as automotive, aerospace, and manufacturing 1.

Role of the 4358810 Pressure Sensor in Truck Operations

The Cummins 4358810 Pressure Sensor monitors pressure levels in critical systems such as the fuel system, brake system, and engine compartments. It provides data that helps maintain optimal performance by ensuring pressure levels remain within specified parameters. This data is essential for the truck’s electronic control unit (ECU) to make adjustments and maintain efficiency 2.

Key Features of the 4358810 Pressure Sensor

The Cummins 4358810 Pressure Sensor features a robust design built to withstand harsh commercial truck environments. Constructed using high-quality materials, it ensures durability and reliability. Technological advancements enhance its performance, providing accurate and consistent pressure readings, contributing to its effectiveness in demanding truck operations 3.

Benefits of Using the 4358810 Pressure Sensor

Incorporating the Cummins 4358810 Pressure Sensor into truck systems offers several advantages. It improves efficiency by ensuring systems operate within optimal pressure ranges. Enhanced safety is another benefit, as accurate pressure monitoring helps prevent system failures that could lead to accidents. Additionally, the use of this sensor can result in potential cost savings for fleet operators by reducing the need for frequent maintenance and repairs due to system malfunctions 4.

Installation and Integration

Proper installation and integration of the Cummins 4358810 Pressure Sensor into truck systems are vital for its optimal performance. Correct placement and secure connection are necessary to ensure accurate pressure readings. Guidelines for installation should be followed to avoid issues that could affect the sensor’s functionality and the overall performance of the truck 5.

Troubleshooting and Maintenance

Common issues with the Cummins 4358810 Pressure Sensor include inaccurate readings or sensor failure. Troubleshooting steps may involve checking connections, inspecting for physical damage, and ensuring the sensor is correctly installed. Regular maintenance, such as cleaning and inspecting the sensor for wear, can help ensure its longevity and reliable operation.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality in manufacturing automotive components, Cummins plays a significant role in the automotive and commercial truck industry. The company’s commitment to advancing technology and improving product performance is evident in its wide range of components, including the 4358810 Pressure Sensor.

Applications and Use Cases

The Cummins 4358810 Pressure Sensor is utilized in various commercial truck applications, including monitoring fuel system pressure, brake system pressure, and engine compartment pressure. Real-world scenarios demonstrate its effectiveness in ensuring systems operate efficiently and safely, contributing to the overall performance and reliability of commercial trucks.

Future Developments and Innovations

Advancements in pressure sensor technology may further enhance truck performance and efficiency. Potential future developments could include improved accuracy, increased durability, and integration with advanced diagnostic systems. These innovations aim to provide even greater benefits to commercial truck operators, including enhanced safety, improved efficiency, and reduced maintenance costs.

Cummins Pressure Sensor 4358810 Compatibility

The Cummins Pressure Sensor part number 4358810 is designed to fit a variety of Cummins engines, ensuring precise monitoring of pressure levels critical for engine performance and safety. This sensor is compatible with the following engine models:

15N Series

- 15N CM2380 M104B

6C Series

- 6C8.3

B Series

- B4.5 CM2350 B129B

- B5.6 CM2670 B152B

- B5.9 GAS PLUS CM556

- B6.7 CM2350 B135B

- B6.7 CM2670 B153B

- B6.7 CM2670 B164C

- B6.7 G CMOH6.0 B125

D Series

- D4.0 CM2620 D103B

F Series

- F3.8 CM2620 F137B

- F4.5 CM2620 F139B

ISB/ISD Series

- ISB/ISD4.5 CM2150 B119

- ISB/ISD6.7 CM2150 SN

- ISB3.9 CM2220 B107

- ISB4.5 CM2350 B104

- ISB5.9 CM2880 B127

- ISB5.9G CM2180

ISBE Series

- ISBE CM2150

- ISBE4 CM850

ISC Series

- ISC CM2150

- ISC CM850

- ISC8.3 CM2250

ISD Series

- ISD4.5 CM2220 D108

ISG Series

- ISG11 CM2880 G108

This sensor plays a role in maintaining the operational integrity of these engines by providing accurate pressure readings, which are essential for the engine control unit (ECU) to adjust fuel injection, timing, and other parameters for optimal performance.

Role of Part 4358810 Pressure Sensor in Engine Systems

The Part 4358810 Pressure Sensor is a component in maintaining the optimal performance of various engine systems. Its primary function is to monitor and relay pressure data within the engine oil and engine oil cooler systems.

Engine Oil System

In the engine oil system, the pressure sensor continuously measures the pressure of the engine oil. This data is vital for ensuring that the oil is circulating at the correct pressure, which is necessary for proper lubrication of engine components. Inadequate oil pressure can lead to increased friction and wear on engine parts, potentially resulting in severe engine damage. The sensor sends real-time data to the Engine Control Module (ECM), allowing for immediate adjustments to maintain optimal oil pressure.

Engine Oil Cooler

The engine oil cooler is another system where the pressure sensor plays a significant role. By monitoring the pressure within the cooler, the sensor helps ensure that the oil is effectively cooled before it is recirculated through the engine. This is particularly important in high-performance or high-stress engines where oil temperatures can rise quickly. The pressure data from the sensor allows the ECM to make necessary adjustments to the oil flow, ensuring that the oil remains within the desired temperature range.

Oil Cooler

Similarly, in the oil cooler system, the pressure sensor ensures that the oil is cooled efficiently. The sensor’s readings help in detecting any anomalies in the cooling process, such as blockages or leaks, allowing for timely intervention to prevent engine overheating.

Engine Control Module (ECM)

The ECM relies heavily on the data provided by the pressure sensor to make informed decisions about engine operation. By integrating pressure data with other sensor inputs, the ECM can optimize fuel injection, ignition timing, and other critical parameters. This results in improved engine efficiency, reduced emissions, and enhanced overall performance.

Conclusion

The Cummins 4358810 Pressure Sensor is a key component in the engine oil, engine oil cooler, and oil cooler systems. Its accurate pressure readings enable the ECM to make real-time adjustments, ensuring that the engine operates within safe parameters. This not only enhances engine performance but also contributes to the longevity and reliability of the engine.

-

Hiereth, H., Prenninger, P., & Drexl, K. W. (2010). Charging the Internal Combustion Engine. Springer.

↩ -

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩ -

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ -

Eret, A. (2024). Dynamic and Fatigue Assessment of Heavy-Duty Engine Valves. Springer Nature.

↩ -

Cummins Inc. (n.d.). Owners Manual. Bulletin Number 5504513.

↩

SPECIFICATIONS

BILL OF MATERIALS

| Name | Quantity | Part Number |

|---|---|---|

| O Ring Seal | 1 | 4010519 |

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.